A kind of artificial stone and preparation method thereof

A technology of artificial stone and quartz, which is applied in the field of artificial stone and its preparation, can solve the problems of weak impermeability and moisture resistance, poor antibacterial function of stone, and high production process cost, so as to enhance moisture, improve gloss, and improve health performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

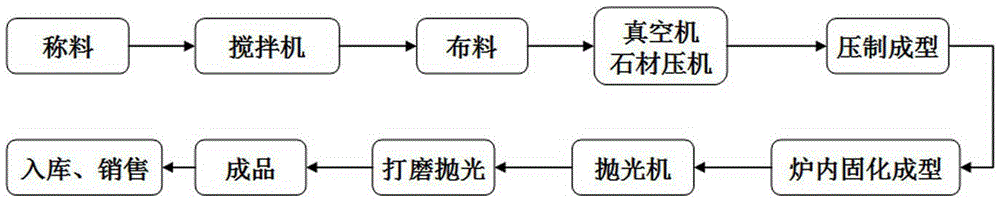

[0035] according to figure 1 Schematic diagram of the implementation. Weigh the raw materials according to the weight of each component specified in Table 1 below, the specification of the quartz used is 1000 mesh, the specification of the cullet is 4~6 mesh, the curing agent used is benzoyl peroxide, and the coupling agent is silane coupling agent. The heavy metals used for alloy resin and alloy powder are iron and zinc, the resin used for alloy resin is polyethylene resin, and the gel used for alloy powder is polyacrylamide gel. Mix the raw materials evenly with a mixer, and then put them in the mold Cloth, get the blank, use a vacuum machine to extract the air in the blank to a vacuum degree of -0.1MPa, use a stone press to press the blank into shape, and the pressing specification is 50 tons / m 2 , the pressing time is 20 minutes, and then it is solidified and formed in the furnace, the solidification temperature is 60°C, the solidification time is 120 minutes, and the gre...

Embodiment 2

[0037] according to figure 1 Schematic diagram of the implementation. Weigh raw materials according to the weight of each component specified in Table 1 below, the specification of quartz used is 800 mesh, the specification of cullet is 8~16 mesh, the curing agent used is methyl ethyl ketone peroxide, and the coupling agent is silane coupling agent , the heavy metals used for alloy resin and alloy powder are copper and lead, the resin used for alloy resin is polypropylene resin, the gel used for alloy powder is agarose gel, the raw materials are mixed evenly with a mixer, and then clothed in a mold to obtain For the billet, use a vacuum machine to extract the air in the billet to a vacuum degree of -0.02MPa, and use a stone press to press the billet into shape, and the pressing specification is 100 tons / m 2 , the pressing time is 10 minutes, and then it is solidified and formed in the furnace. The solidification temperature is 120° C., and the solidification time is 30 minute...

Embodiment 3

[0039] according to figure 1 Schematic diagram of the implementation. Weigh the raw materials according to the weight of each component specified in Table 1 below, the specification of the quartz used is 600 mesh, the specification of the cullet is 26~40 mesh, the curing agent used is tert-butyl peroxybenzoate, and the coupling agent is Silane coupling agent, heavy metals for alloy resin and alloy powder are cadmium and nickel, resin for alloy resin is polystyrene resin, gel for alloy powder is polystyrene gel, mix the raw materials evenly with a mixer, and then Spread the material in the mold to obtain the blank, use a vacuum machine to extract the air in the blank to a vacuum degree of -0.06MPa, and use a stone press to press the blank into shape, and the pressing specification is 200 tons / m 2 , the pressing time is 3 minutes, and then it is solidified and formed in the furnace. The solidification temperature is 80° C., and the solidification time is 100 minutes. The green ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com