Independent transmission lifting mechanism of spinning frame

An independent transmission and lifting mechanism technology, applied in textiles and papermaking, etc., can solve problems such as unstable yarn tension, reduced spinning efficiency, and inability to realize variable range and step-up movement of the yarn guide plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

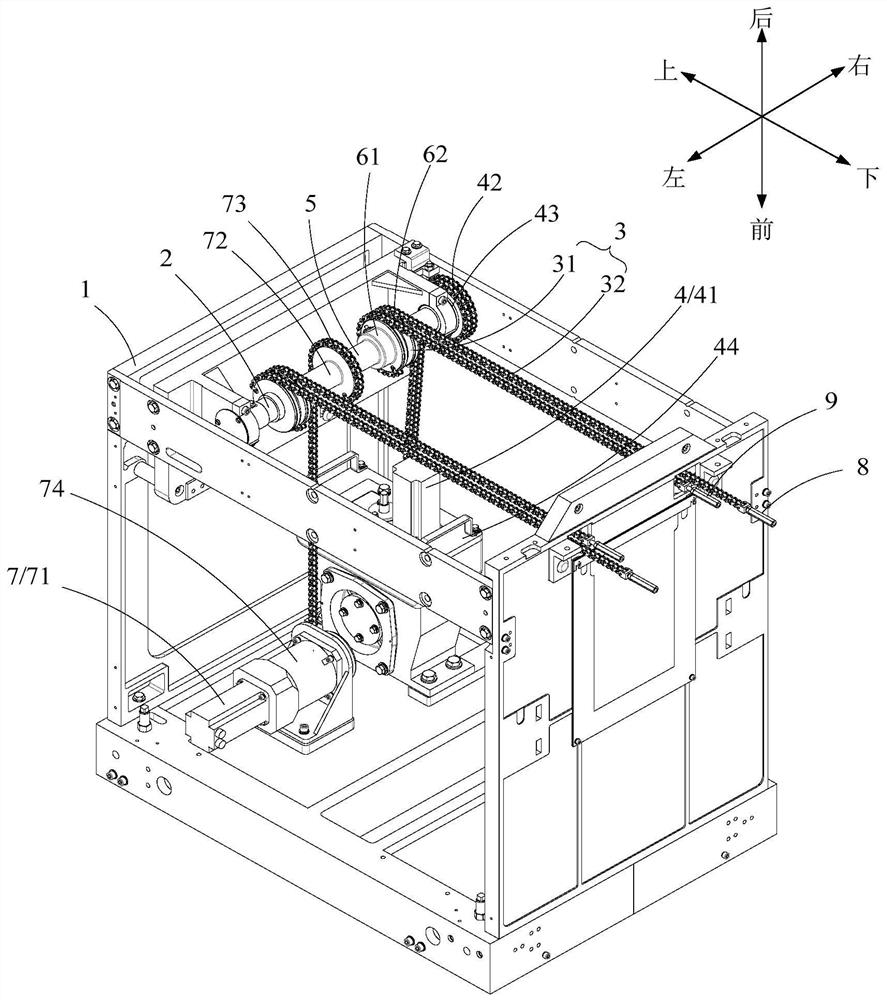

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

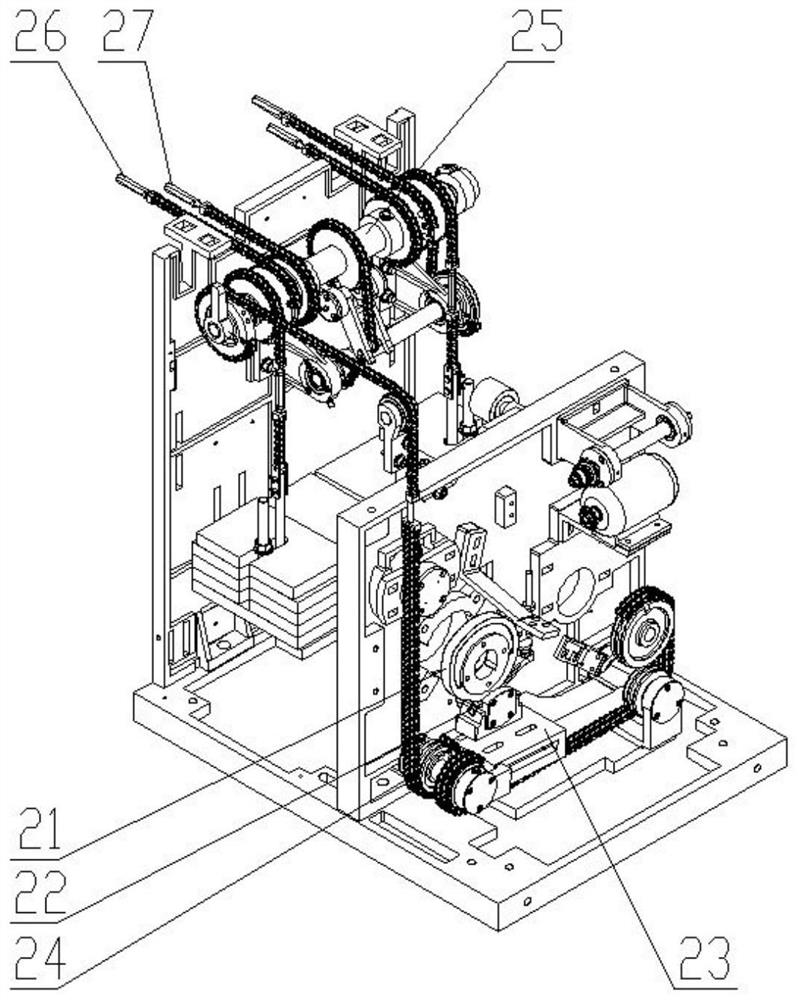

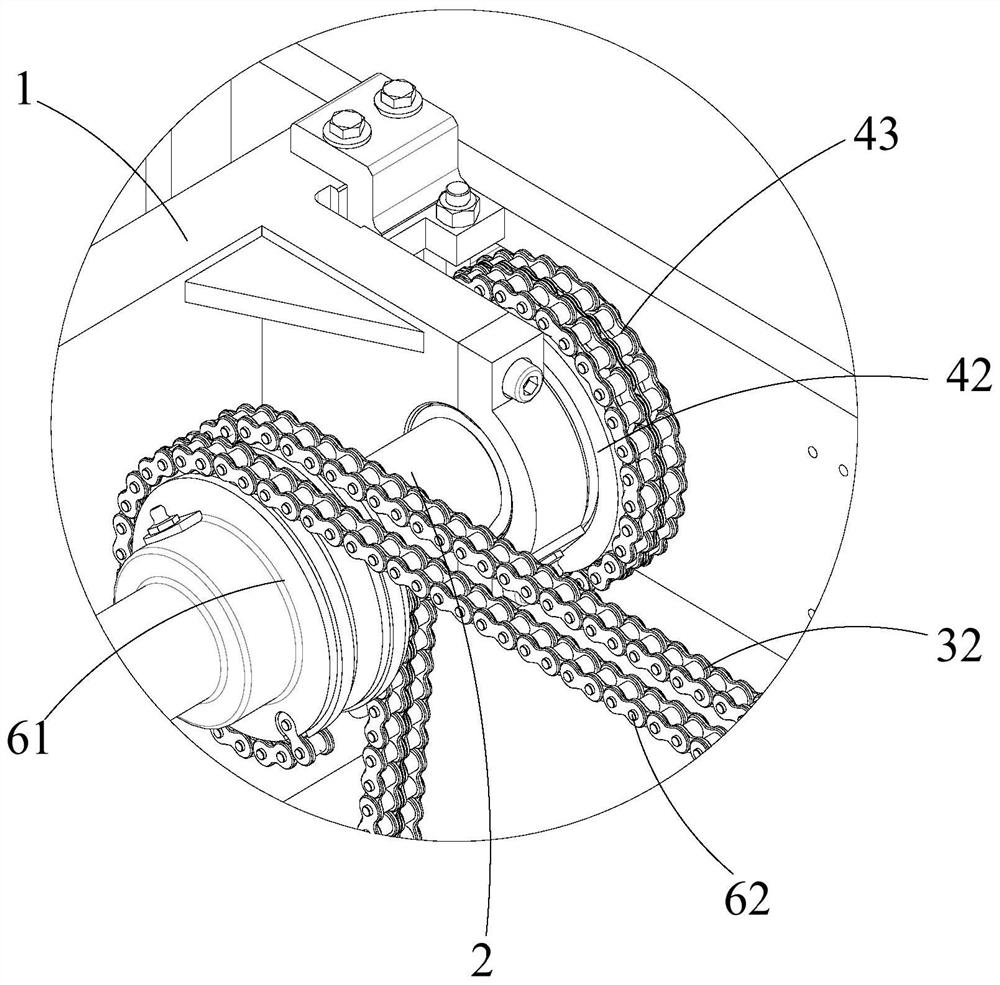

[0034] See figure 2 , the embodiment of the present invention provides an independent transmission and lifting mechanism for spinning frames, including a headstock frame 1, a rotating shaft 2, a ring plate connector 3, a ring plate drive mechanism 4, a rotating cylinder 5, and a yarn guide plate connector 6 And the yarn guide plate driving mechanism 7.

[0035] The rotating shaft 2 extends along the left and right directions, and is axially rotatable and installed on the head frame 1; the upper end of the ring plate connector 3 is flexible, wound on the rotating shaft 2, and fixedly connected with the rotating shaft 2, and the lower end Used for fixed connection with the ring plate, in this embodiment, the lower end is fixedly connected with the ring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com