Prestressed anchor bolt mounting structure and mounting method

A technology of installation structure and installation method, applied in infrastructure engineering, construction and other directions, can solve problems such as hidden safety hazards of anchor bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

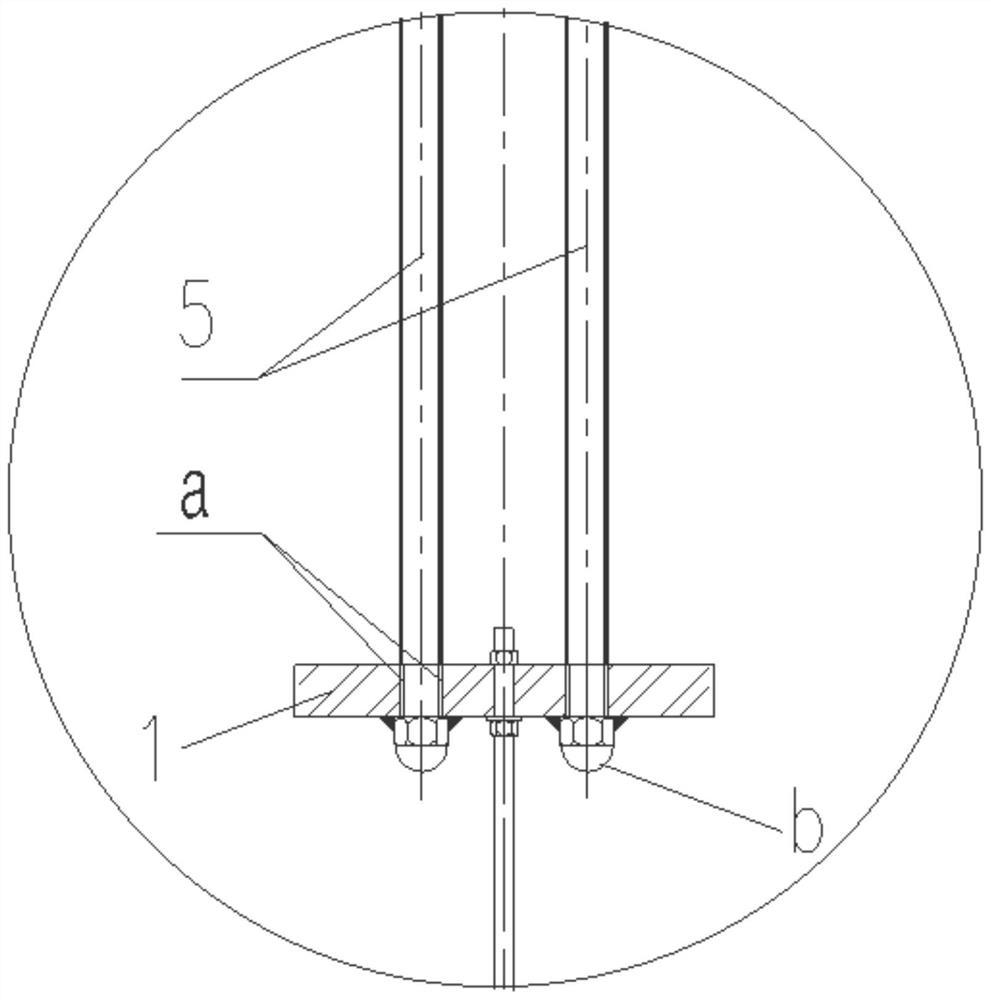

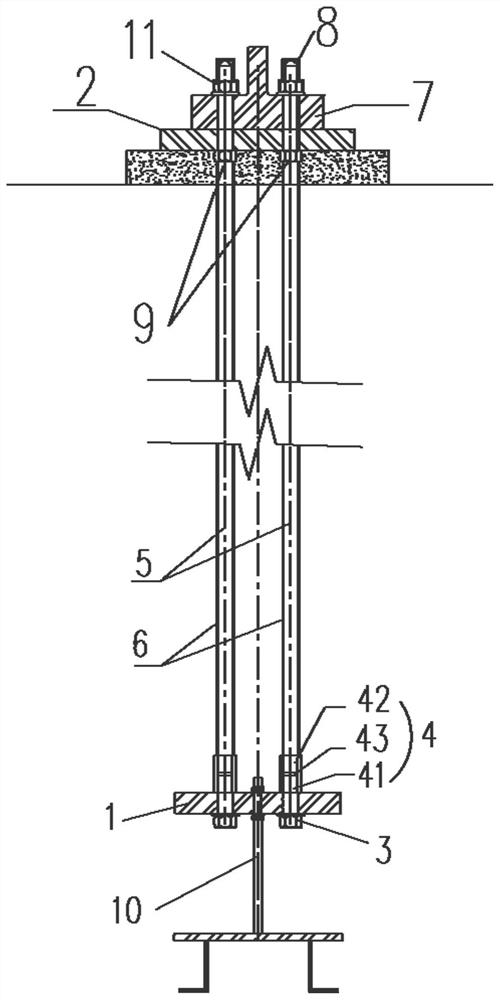

[0034] This embodiment provides a prestressed anchor bolt installation structure, such as figure 2 shown, including:

[0035] The lower anchor plate 1 is provided with a plurality of first through holes;

[0036] The upper anchor plate 2 is set corresponding to the lower anchor plate, and the upper anchor plate 2 is correspondingly provided with a plurality of second through holes;

[0037] Specifically, the upper anchor plate 2 and the lower anchor plate 1 extend along the horizontal direction, so as to play a stabilizing action in concrete. Meanwhile, the upper anchor plate 2 and the lower anchor plate 1 are made of technical materials, such as steel, respectively. The shapes of the first through hole and the second through hole are not limited, and their function is to realize the connection action. In this embodiment, as figure 2 As shown, the first through hole is arranged below the second through hole, and the first through hole and the second through hole are arran...

Embodiment 2

[0058] This embodiment provides a method for installing prestressed anchor bolts, including the following steps:

[0059] Install the threaded sleeve 4 and the bottom bolt 3 on the lower anchor plate 1, so that the bottom bolt 3 is connected to one end of the threaded sleeve 4 through the lower anchor plate 1;

[0060] One end of the anchor bolt 5 is connected to the upper anchor plate 2, and the other end is connected to the other end of the threaded sleeve 4 to form 5 anchor bolt frames;

[0061] Concrete is poured on the 5 anchor bolts, and the concrete is poured to the position below the upper anchor plate 2.

[0062] When the anchor bolt 5 breaks, the upper anchor bolt 5 is taken out, and then the remaining anchor bolt 5 heads are removed from the threaded sleeve 4 by a spark machine, and the complete anchor bolt is installed on the On the threaded sleeve 4.

[0063] After pouring the concrete, the figure 2 As shown, the position of the concrete will extend to the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com