Buffering device

A buffer device and buffer tube technology, applied in the direction of coil springs, shock absorbers, springs, etc., can solve the problems of poor vibration reduction effect and low specific damping coefficient, and achieve good energy dissipation effect, large specific damping coefficient, The effect of good mechanical properties and energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

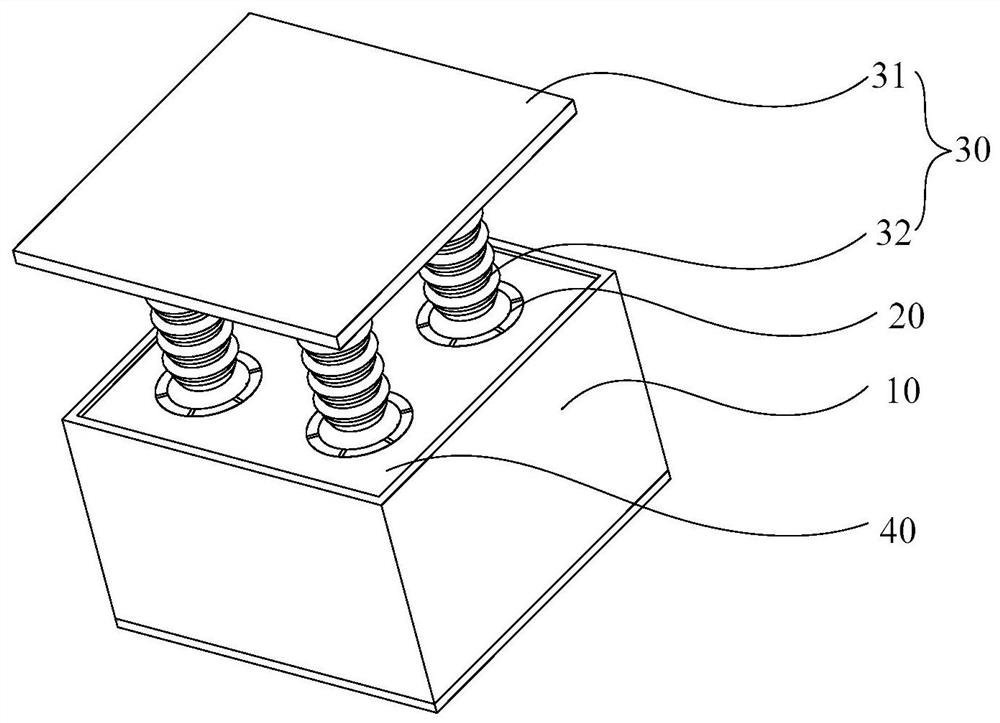

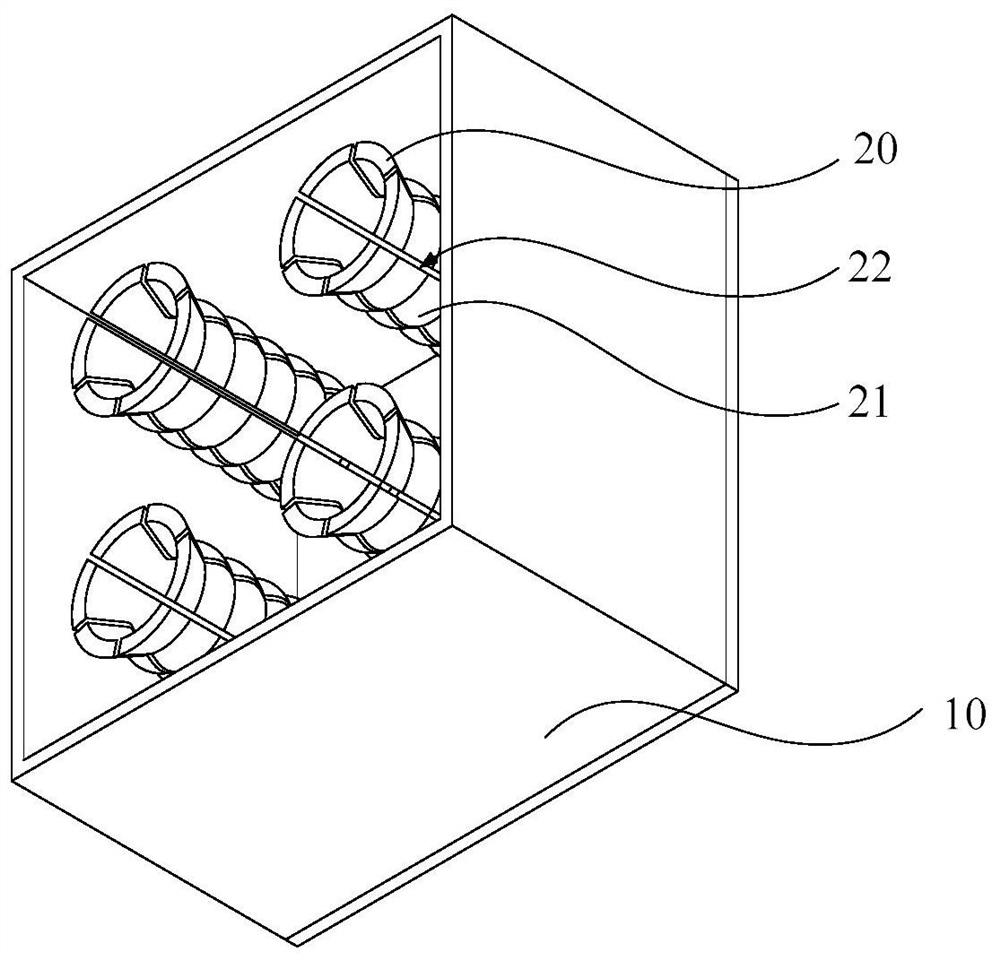

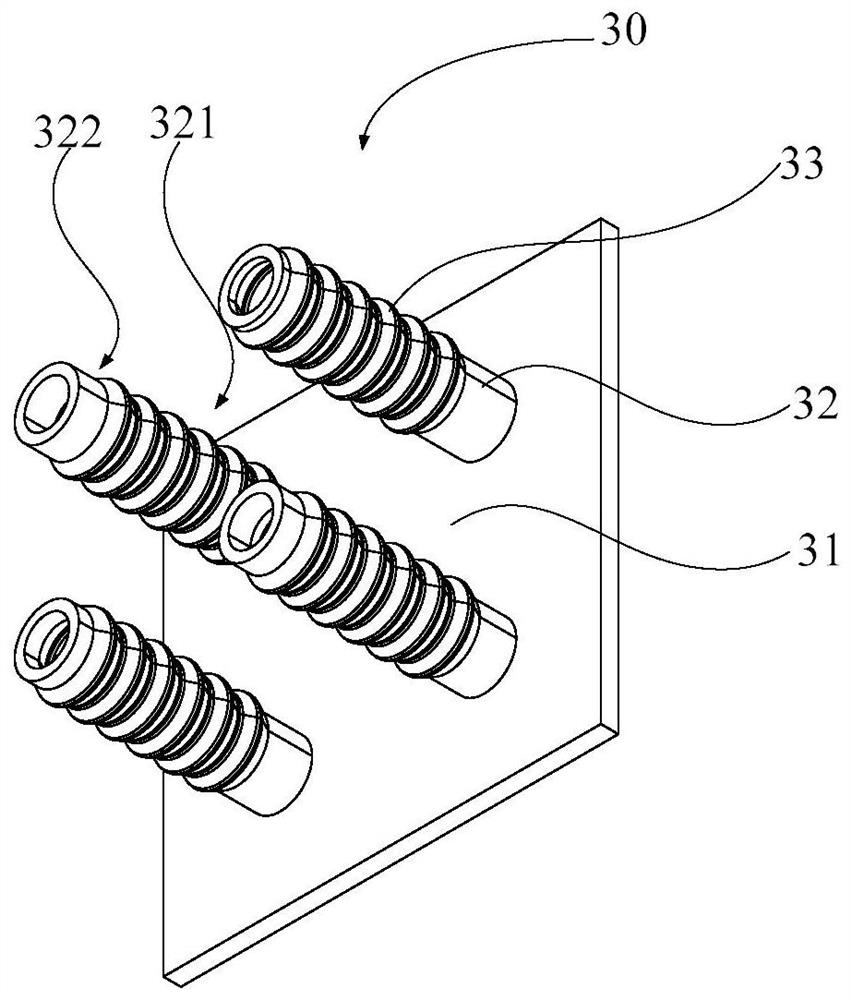

[0075] The buffer device includes: housing 10, four buffer tube 20, support member 30, elastic portion 40, and a resilient support. The support 30 includes four support columns 32 and support plates 31, and the length of the four support post 32 is four, and the length of the support tail section 322 is 5 mm, 3.75 mm, 2.5 mm, 1.25 mm, respectively. The phase difference between the support tail section 322 is 1.25 mm. This buffer device is from 1 to 2-3-4 structures.

example 2

[0077]The buffer device includes: housing 10, four buffer tube 20, support member 30, elastic portion 40, and a resilient support. The support member 30 includes four support columns 32 and support plates 31, and the length of the four support posts 32 is two, and the length of the support tail section of the two support post 32 is different, and the support tail section 322 The length is 5 mm, 2.5 mm, respectively. The phase difference between the support tail section 322 is 2.5 mm. The buffer device is from 1 to 3-1-3 structures.

[0078] Contrast 1

[0079] The buffer device includes a housing 10, a buffer tube 20, a support member 30, an elastic portion 40, and an elastic support. The support member 30 includes a support post 32 and a support plate 31 that support the support post 32 of 5 mm. This buffer device is a single cell structure

[0080] Contrast 2

[0081] The buffer device includes: housing 10, four buffer tube 20, support member 30, elastic portion 40, and a resili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com