Crop stalk conveying device for test bed

A technology of conveying device and test bench, applied in the field of agricultural machinery, can solve the problems of poor versatility, fixed and unadjustable height of the stalk conveying device, inability to realize stalk cutting test, etc., and achieves the effect of convenient adjustment and avoiding stalk pinching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

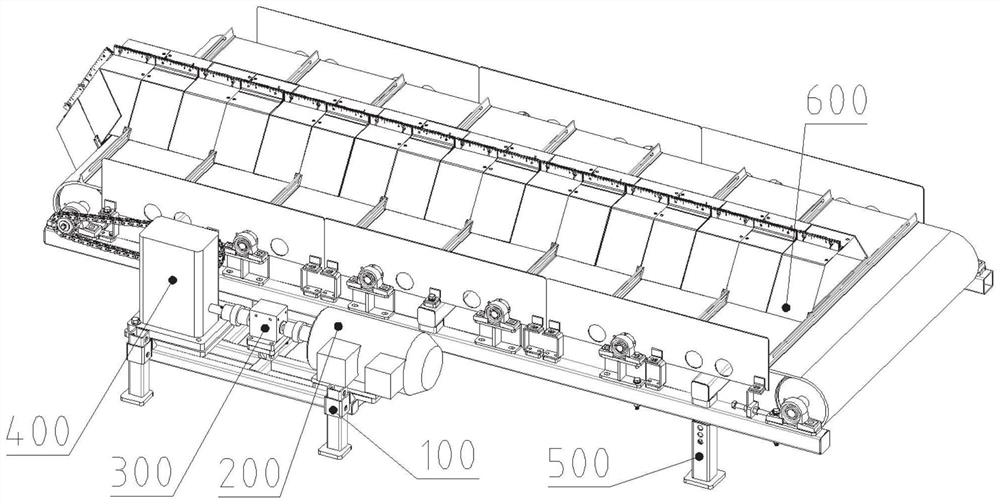

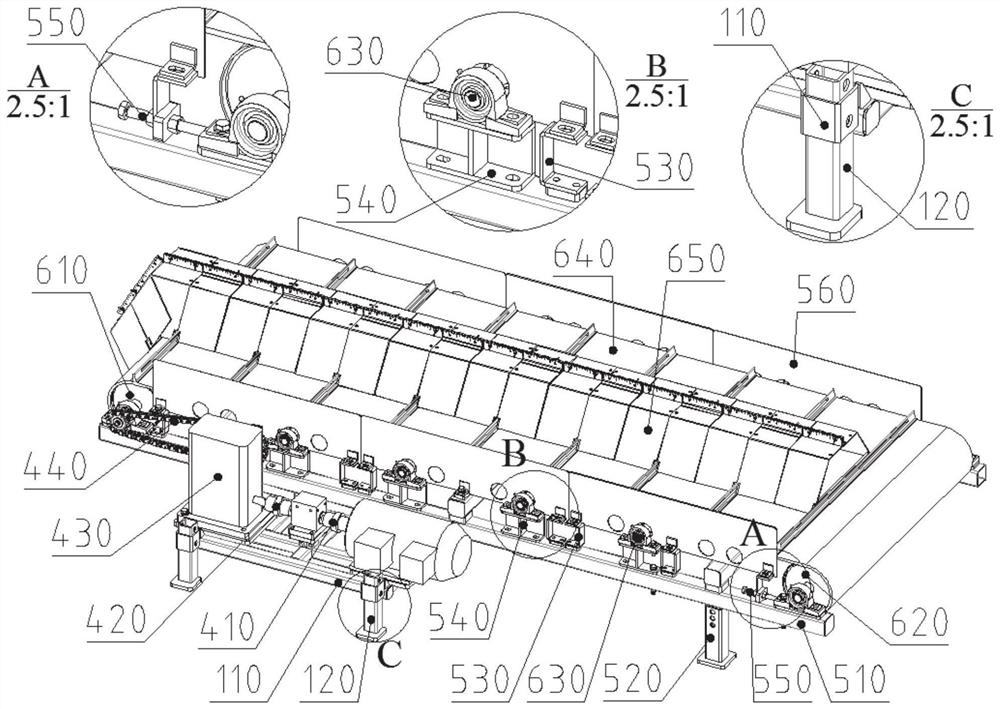

[0039] Such as figure 1 As shown, in a typical embodiment of the present invention, a test bench is disclosed as a crop stalk conveying device, including a first frame 100, a second frame 500, a driving mechanism 200, a torque sensor 300, and a transmission mechanism 400 , the stalk conveying mechanism 600, the stalk clamping mechanism. The drive mechanism 200, the torque sensor 300, and a part of the transmission mechanism 400 are fixedly installed in sequence on the first frame 100; the stalk conveying mechanism 600 and the stalk clamping mechanism are fixedly installed on the second frame 500, wherein the drive mechanism 200 passes The transmission mechanism 400 is connected to the stem conveying mechanism, and the driving mechanism 200 and / or the transmission mechanism 400 is also connected to the torque sensor 300, wherein the stem conveying mechanism is also connected to the stem clamping mechanism, and the stem clamping mechanism can clamp the crop stem.

[0040] In ye...

Embodiment 2

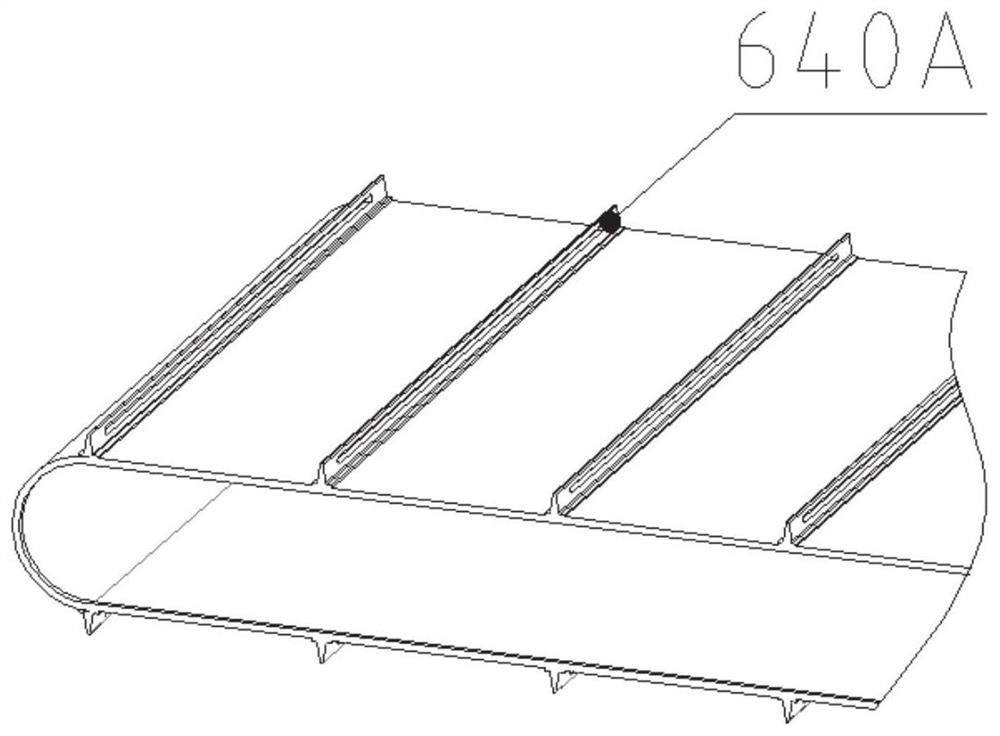

[0065] In yet another embodiment, such as Figure 6 and Figure 7 As shown, the test bench is used as a crop stalk conveying device and also includes a second clamping mechanism 700 detachably installed on the baffle plate 640A of the conveyor belt 640, including a square washer 710 for channel steel, a third connecting plate 720, a second fixing The clamping part 730 and the second movable clamping part 740 .

[0066] The square-inclined washers 710 for the channel steel include multiple ones, two of which are welded on the third connecting plate 720 with the square-inclined washers 710 for the channel steel, and two of which are welded on the channel steel with the square-inclined washers 710 for the channel steel.

[0067] Such as Figure 6 As shown, the second fixed clamping member 730 is a channel steel, one side of the channel steel is provided with two threaded holes for assembling to the conveyor belt baffle, and the other side is provided with a threaded hole for in...

Embodiment 3

[0070] In yet another embodiment, the crop stalk conveying device used on the test bench also includes a controller and a display; the controller is used to control the driving mechanism, and the torque sensor 300 and the servo motor provide real-time feedback on the transmission power, transmission speed and other operations during the test process. parameter, and display the parameter value on the display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com