Novel bone fracture plate for tibia posterior lateral plateau

A bone plate, posterolateral technology, applied in the field of new tibial posterolateral platform plate, can solve the problems of increasing the risk of secondary fractures, unfavorable distal temporary fixation, determining the position of the bone plate, unfavorable bone and bone plate fitting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

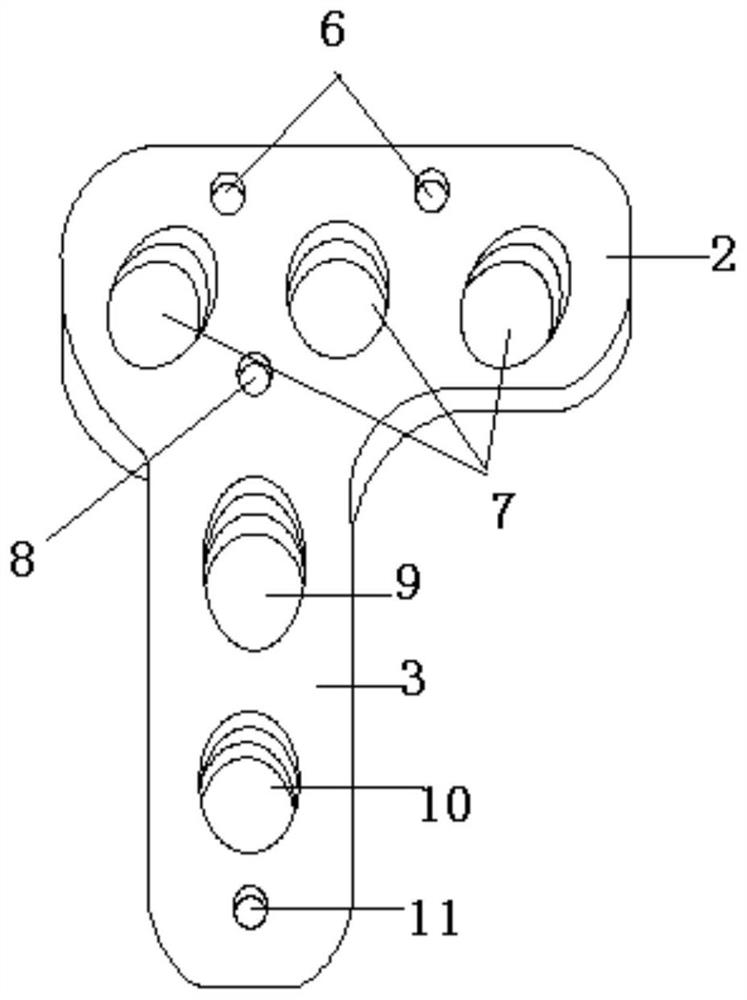

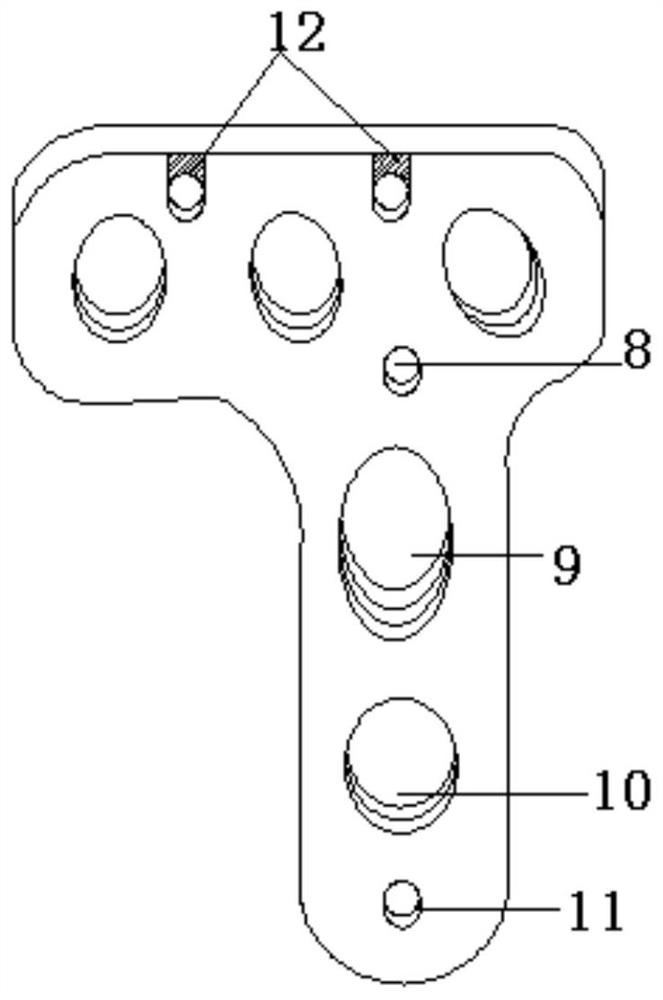

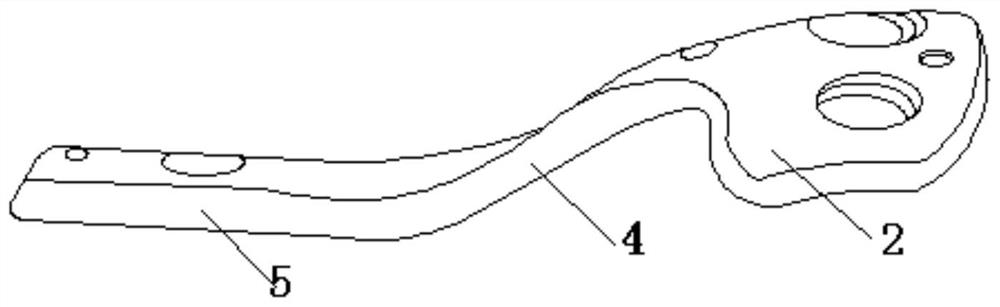

[0018] like Figure 1 - Figure 3 A novel tibia rear outer platform bone plate, including a bone plate body 1, and the bone plate body 1 is integrally being L-shaped, divided into near-platform segments 2 and the remote stage 3, the bone plate body thickness of 2 -2.5MM, the length is 3.3-5.3 cm, the width is 0.8-3.3cm, the near platform segment 2 is a curved curved arch structure, in line with the inside of the tibia, and the far platform section 3 adopts a bevel Structure 4 and the planar structure 5, the bevel structure 4 is smoothly connected to the near-platform segment 2, and the near platform segment 2 has near to bottom, and the near-platform lock hole 6 and the near-platform lock hole 7 are seated from top to bottom. The platform lock hole 7 has a plurality of arrangement along the near stage segment 2, and the far platform segment 3 opens from top to bottom, and the upper platform is on the upper platform on the upper platform, the upper platform is locked. 9, The remote l...

Embodiment 2

[0020] like Figure 1 - Figure 3 A new type of tibia, a rear outer platform, including a bone plate body 1, and the bone plate body 1 is integrally in shape, and the bone plate body 1 is close to the tibial platform portion according to the position when the bone plate body 1 is used. For near platform 2, it is far from the tibial platform portion as a remote platform section 3, and the edge of the bone plate body 1 is a smooth curved surface structure, which can reduce tendon, ligament, soft tissue friction damage and foreign body sensing, the bone plate body thickness. It is 2-2.5 mm, the length is 3.3-5.3cm, the width is 0.8-3.3cm, the near platform 2 is a curved curved curved curved structure, which is in line with the inside of the tibia, and the near platform 2 2 The thin design is thinner, the thinner is 2mm, which can reduce the friction damage of tendons, ligaments, soft tissues, which uses a slope structure 4 and a planar structure 5 to facilitate the insertion of the bon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com