Ulna far-end inner side bone fracture plate

A bone plate and ulna technology, applied in the field of medical devices, can solve problems such as inability to fit the bone to the bone plate, inability to fix comminuted fractures or fixed reduction of small bone fragments, and long operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

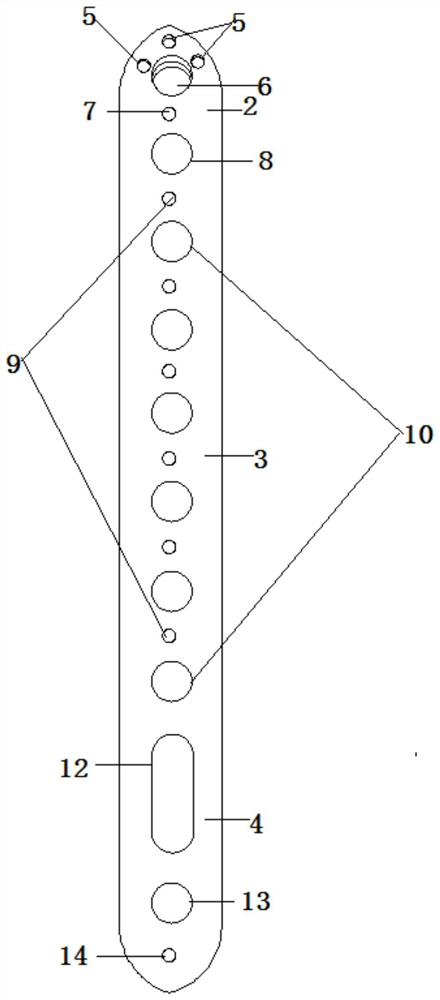

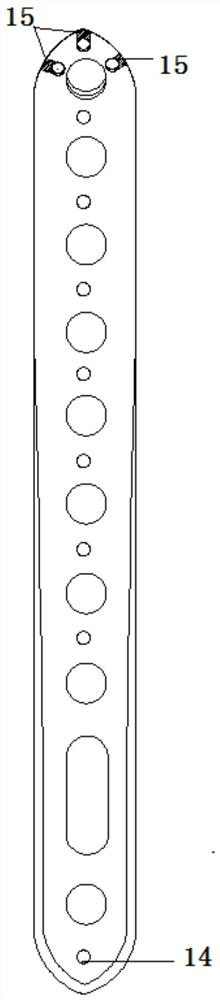

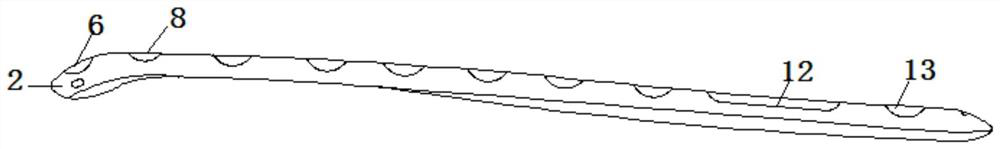

[0017] Such as Figure 1-Figure 3 A bone plate at the medial distal end of the ulna is shown, comprising a bone plate 1, the bone plate 1 has a thickness of 1.5-2.5 mm, a length of 2.5-9 cm, and a width of 0.5-0.9 cm, and the bone plate 1 is divided into proximal The wrist joint part 2, the middle section 3 and the distal wrist joint part 4, the proximal wrist joint part 2 is an arc-shaped structure, with both sides curved inwardly, conforming to the anatomical structure characteristics of the ulnar styloid process, and the proximal wrist joint part 2 is from top to bottom There are near wrist Kirschner hole 5, near wrist locking hole 6, near wrist lower Kirschner hole 7 and near wrist lower locking hole 8, said near wrist Kirschner hole 7 is provided with 3, is located in near wrist Above and on the left and right sides of the locking hole 6, the sections of the middle section 3 and the distal wrist joint part 4 are arc-shaped, conforming to the anatomical structure of the ul...

Embodiment 2

[0019] Such as Figure 1-Figure 3 A bone plate at the medial end of the distal ulna is shown, comprising a bone plate 1, the thickness of the bone plate 1 is 1.5-2.5mm, the length is 2.5-9cm, and the width is 0.5-0.9cm, and the edge of the bone plate 1 is smooth Curved surface structure, reducing tendons, ligaments, soft tissue friction damage and foreign body sensation. The bone plate 1 is divided into a proximal part 2, a middle part 3 and a distal part 4. The proximal part 2 is an arc structure. The two sides are curved inwardly and are designed to be thinner, conforming to the anatomical characteristics of the ulnar styloid process, and can reduce the friction damage of tendons, ligaments, and soft tissues. Wrist locking hole 6, near wrist lower Kirschner hole 7 and near wrist lower locking hole 8, said near wrist Kirschner hole 7 is provided with 3, is positioned at near wrist locking hole 6 top and left and right sides, said near wrist K-wire hole 5 in the wrist and K-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com