Bone fracture plate for tibia posterior medial plateau

A bone plate and posteromedial technology, applied in the field of tibial posteromedial plate bone plate, can solve the problems of bone plate length, wound infection, and many locking nail holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

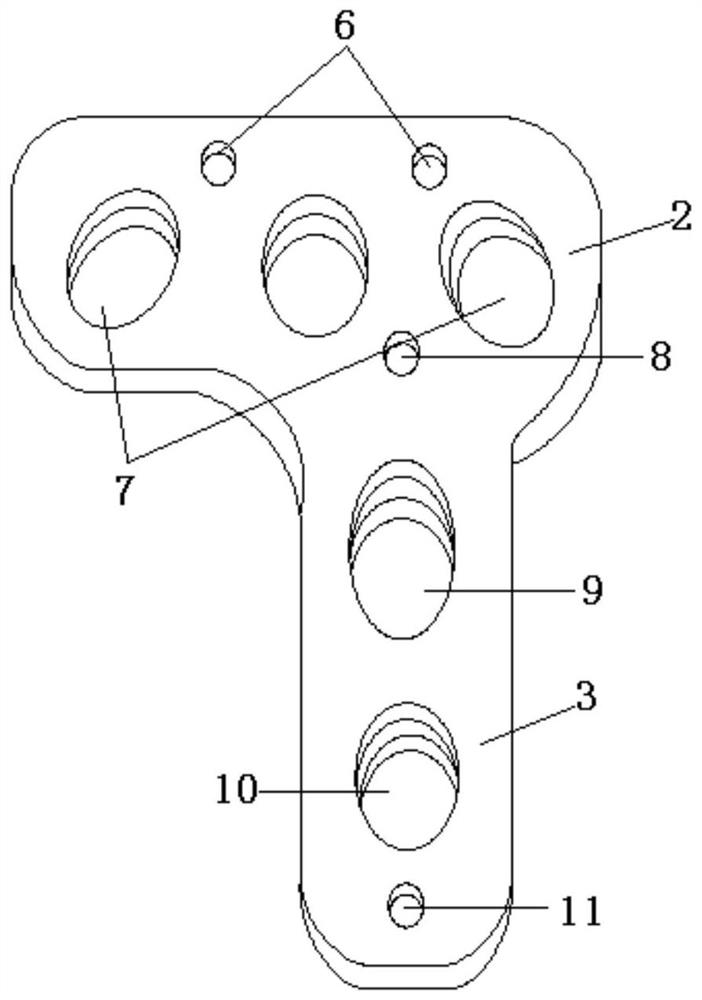

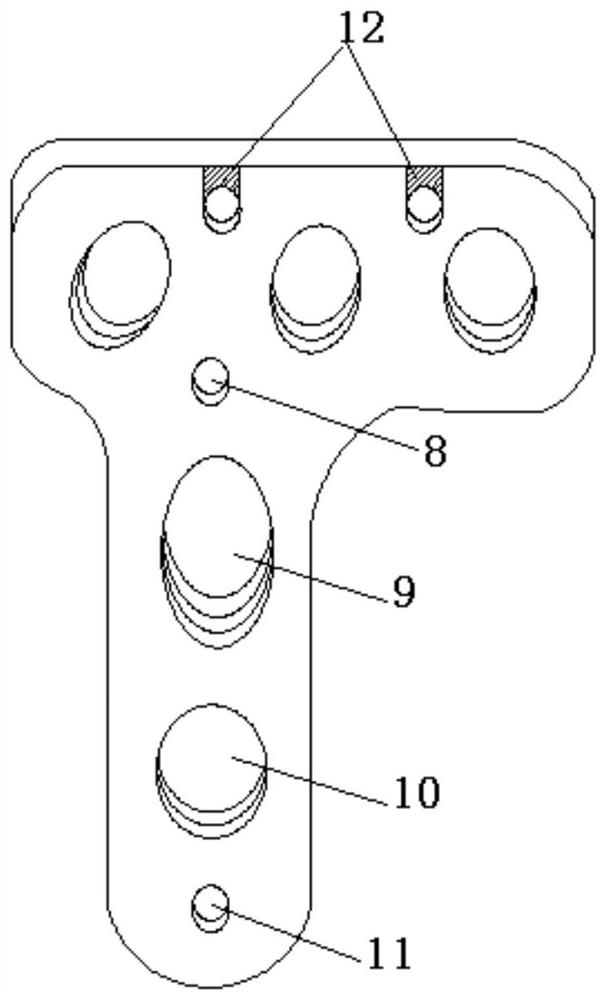

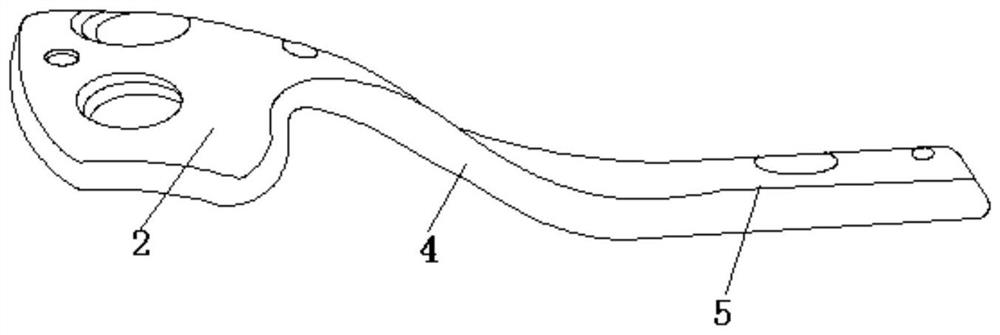

[0018] Such as Figure 1-Figure 3 A posteromedial tibial plate bone plate is shown, which includes a bone plate body 1. The bone plate body 1 is L-shaped as a whole, and is divided into a proximal platform segment 2 and a distal platform segment 3. The bone plate body 1 has a thickness of 2 -2.5mm, the length is 3.3-5.5cm, and the width is 0.8-3.4cm. The proximal platform section 2 is an inwardly curved arc surface structure, which conforms to the anatomical structure characteristics of the posteromedial platform of the tibia. The distal platform section 3 adopts a slope Structure 4 and planar structure 5, the slope structure 4 is smoothly connected with the near-platform section 2, and the near-platform section 2 is sequentially provided with a near-platform Kirschner hole 6 and a near-platform locking hole 7 from top to bottom. The platform locking holes 7 are provided with a plurality of them, and are arranged in a row along the near platform section 2, and the said far pla...

Embodiment 2

[0020] Such as Figure 1-Figure 3 A posteromedial tibial plateau bone plate is shown, which includes a bone plate body 1, which is L-shaped as a whole. According to the position of the bone plate body 1 when it is used, the part of the bone plate body 1 close to the tibial plateau is set as The proximal platform segment 2 and the part away from the tibial plateau are set as the distal platform segment 3. The edge of the bone plate body 1 is a smooth arc surface structure, which can reduce frictional damage and foreign body sensation of tendons, ligaments, and soft tissues. The thickness of the bone plate body 1 is It is 2-2.5mm, the length is 3.3-5.5cm, and the width is 0.8-3.4cm. The near-platform section 2 is an inwardly curved arc surface structure, which conforms to the anatomical characteristics of the posteromedial tibial platform. The near-platform section 2 The design is relatively thin, and the thinnest part is 2 mm. The distal platform section 3 adopts a slope struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com