PVC wear-resistant leather and preparation method thereof

A PVC resin and leather technology, applied in textiles and papermaking, etc., can solve the problems of PVC leather or leather wear, wear-resistant protective layer failure, poor wear resistance of PVC leather, etc., to improve PVC performance, reduce friction damage, Effect of improving dispersion uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

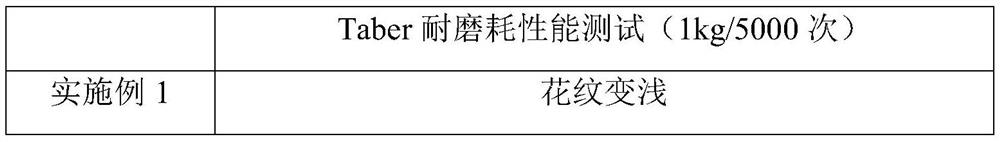

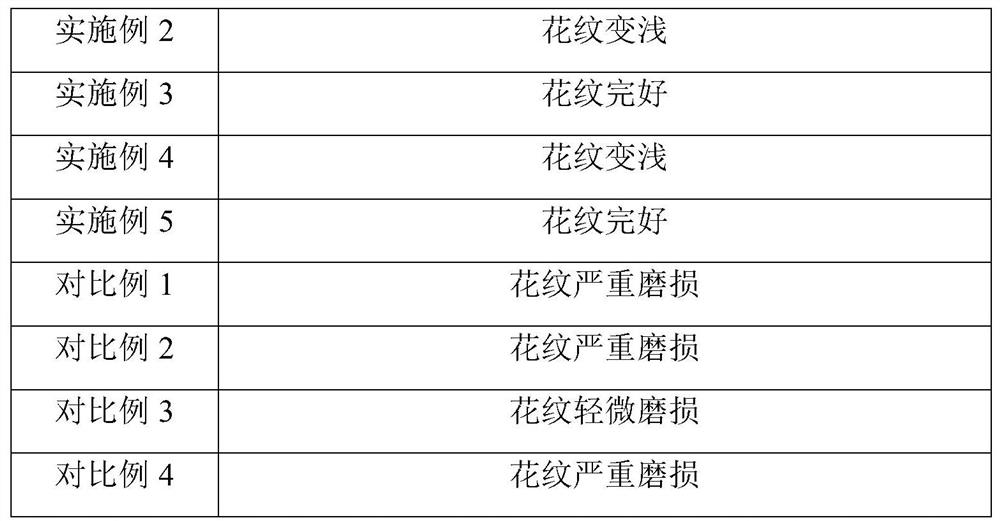

Examples

Embodiment 1

[0025] A kind of PVC wear-resistant leather and preparation method thereof

[0026] PVC wear-resistant leather, including the following raw materials in parts by weight: 50 parts of PVC resin, 1 part of methyltriethylsilane, 10 parts of epoxy soybean oil, 1 part of polyurethane, 2 parts of tributyl citrate, modified 10 parts of permanent alumina, 3 parts of silicon carbide, 1 part of antistatic agent, 5 parts to 8 parts of wear agent, and 1 part to 5 parts of foaming agent; the wear agent is polyvinyl chloride powder.

[0027] The preparation of the modified alumina comprises the following steps:

[0028] S1. Put the alumina into a pulverizer and grind it to an alumina powder with an average particle size of 40 μm, add it to absolute ethanol, stir it ultrasonically until it is evenly dispersed, then add magnesium aluminate and 10% ammonia solution in sequence After ultrasonic dispersion, add polyethylene glycol solution with a concentration of 10%, stir until gel appears, con...

Embodiment 2

[0035] A kind of PVC wear-resistant leather and preparation method thereof

[0036] PVC wear-resistant leather, including the following raw materials in parts by weight: 55 parts of PVC resin, 1.5 parts of methyltriethylsilane, 12 parts of epoxy soybean oil, 1.5 parts of polyurethane, 2.5 parts of tributyl citrate, modified 12 parts of permanent alumina, 4 parts of silicon carbide, 1.2 parts of antistatic agent, 6 parts of anti-wear agent, and 2 parts of foaming agent; the anti-wear agent is polyvinyl chloride powder.

[0037] The preparation of the modified alumina comprises the following steps:

[0038] S1. Put the alumina into a pulverizer and grind it to an alumina powder with an average particle size of 40 μm, add it to absolute ethanol, stir it ultrasonically until it is evenly dispersed, then add magnesium aluminate and 10% ammonia solution in sequence After ultrasonic dispersion, add polyethylene glycol solution with a concentration of 10%, stir until gel appears, con...

Embodiment 3

[0045] A kind of PVC wear-resistant leather and preparation method thereof

[0046] PVC wear-resistant leather, including the following raw materials in parts by weight: 60 parts of PVC resin, 2 parts of methyltriethylsilane, 17 parts of epoxy soybean oil, 3 parts of polyurethane, 2 parts of tributyl citrate, modified 15 parts of permanent alumina, 5 parts of silicon carbide, 2 parts of antistatic agent, 5 parts of anti-wear agent, and 3 parts of foaming agent; the anti-wear agent is polyvinyl chloride powder.

[0047] The preparation of the modified alumina comprises the following steps:

[0048] S1. Put the alumina into a pulverizer and grind it to an alumina powder with an average particle size of 40 μm, add it to absolute ethanol, stir it ultrasonically until it is evenly dispersed, then add magnesium aluminate and 10% ammonia solution in sequence After ultrasonic dispersion, add polyethylene glycol solution with a concentration of 10%, stir until gel appears, continue to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com