Distal humerus posterior-lateral bone fracture plate

A bone plate and posterolateral technology, which is applied in the field of posterolateral bone plate at the distal end of the humerus, can solve the problems of few Kirschner wire holes in the bone plate, complex and variable elbow fractures, inconvenient fixation and positioning, etc., to prevent bone necrosis, Highly repeatable, non-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

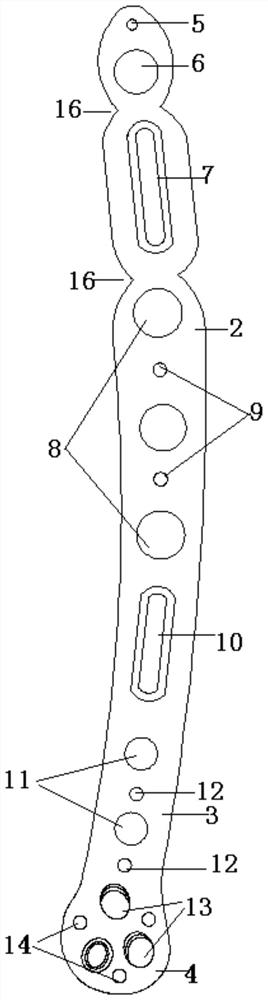

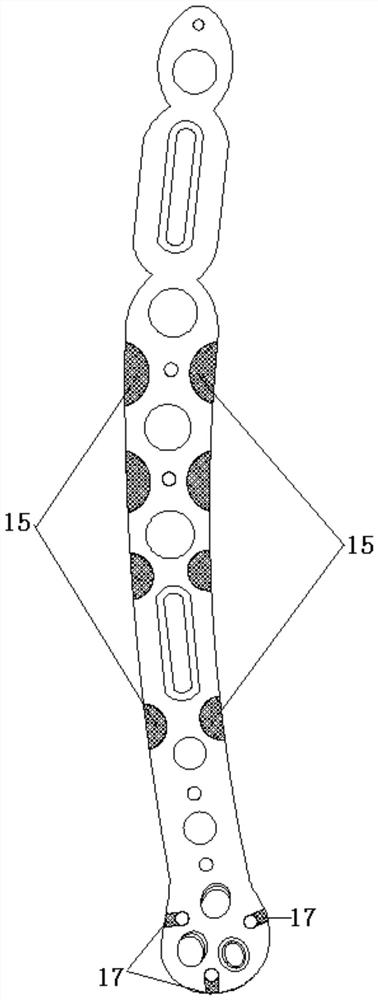

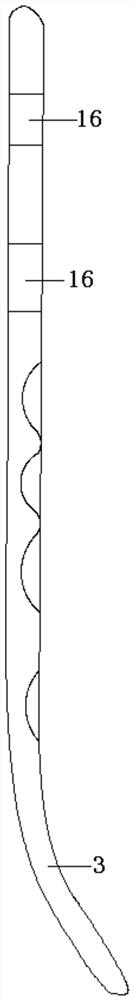

[0022] Such as Figure 1-Figure 3 A posterolateral bone plate of the distal end of the humerus shown includes a bone plate 1, the bone plate 1 has a thickness of 0.2-0.3cm, a length of 8-20cm, and a width of 1.1-1.5cm, and the bone plate 1 is divided into The proximal end 2 of the bone plate and the distal end 3 of the bone plate. The proximal end 2 of the plate is provided with a proximal Kirschner wire hole 5, a proximal locking hole 6, a proximal sliding hole 7 and a proximal lower locking hole 8 from top to bottom, and the proximal lower locking hole 8 is provided with a plurality of There is a proximal lower Kirschner wire hole 9 between adjacent proximal lower locking holes 8, and the distal end 3 of the bone plate is sequentially provided with a distal sliding hole 10, a distal locking hole 11, a distal End Kirschner wire holes 12 and distal lower locking holes 13, the distal locking holes 11 and the distal Kirschner wire holes 12 are all provided with a plurality of t...

Embodiment 2

[0024] Such as Figure 1-Figure 3 A posterolateral bone plate of the distal end of the humerus shown includes a bone plate 1, the bone plate 1 has a thickness of 0.2-0.3cm, a length of 15-20cm, and a width of 1.1-1.5cm, and the edge of the bone plate 1 is Smooth curved surface structure, the bone plate 1 is divided into a proximal end 2 of the bone plate and a distal end 3 of the bone plate, the lower end of the distal end 3 of the bone plate is an enlarged structure 4, and the distal end 3 of the bone plate is relatively close to the bone plate. The end 2 is curved inward, and the proximal end 2 of the bone plate is sequentially opened with a proximal Kirschner wire hole 5 with a diameter of 1.5 mm, a proximal locking hole 6 with a diameter of 3.5 mm, and a proximal sliding hole. 7 and a proximal lower locking hole 8 with a diameter of 3.5mm. The proximal lower locking holes 8 are provided with 3 and distributed equidistantly. Between adjacent proximal lower locking holes 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com