Tempered glass high-temperature continuous baking bending equipment and working method thereof

A tempered glass, high temperature technology, applied in the field of high temperature continuous bending equipment for tempered glass, can solve problems such as glass deviation, local overheating, heating transition, etc., to ensure quality and accuracy, avoid rapid cooling and stiffness, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

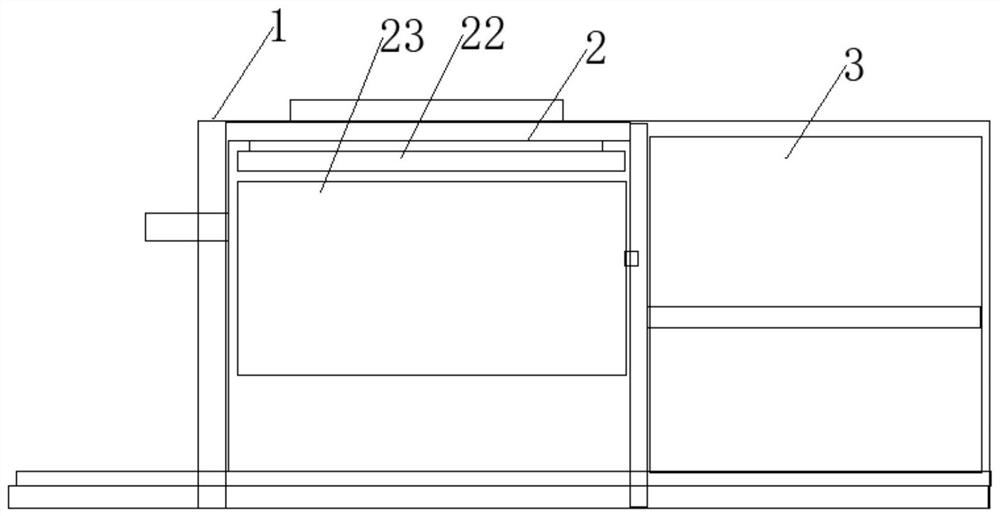

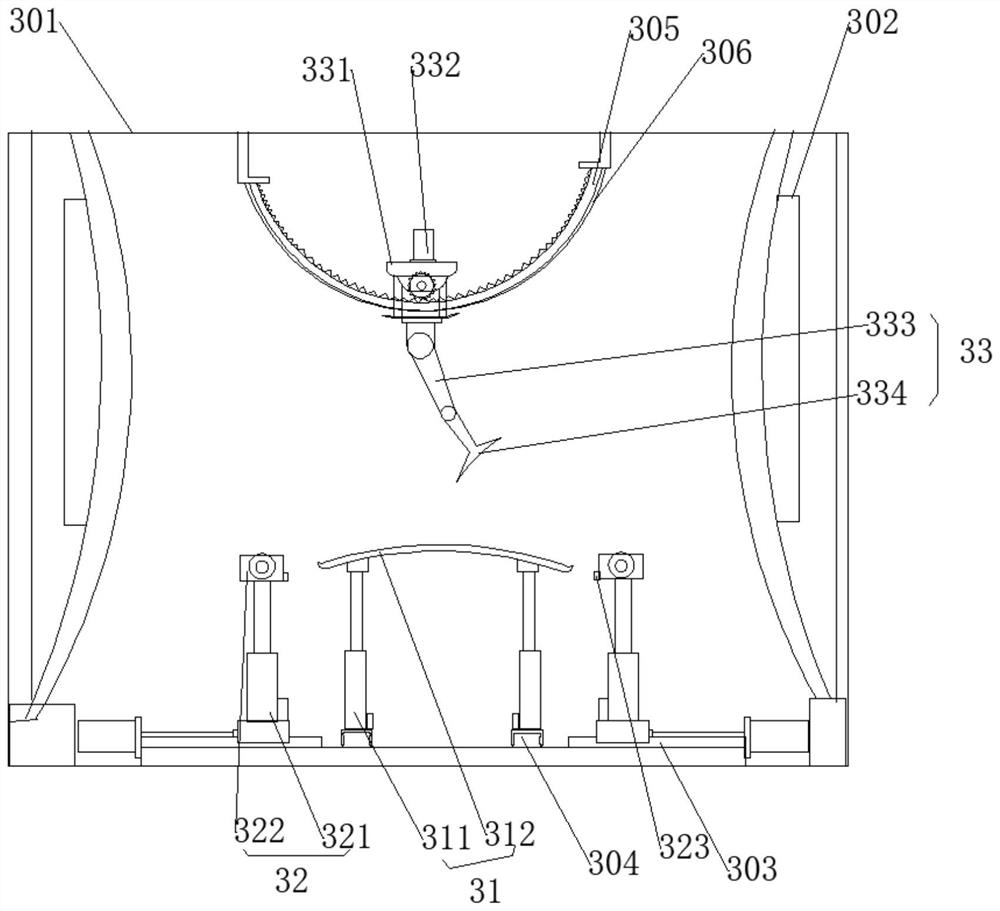

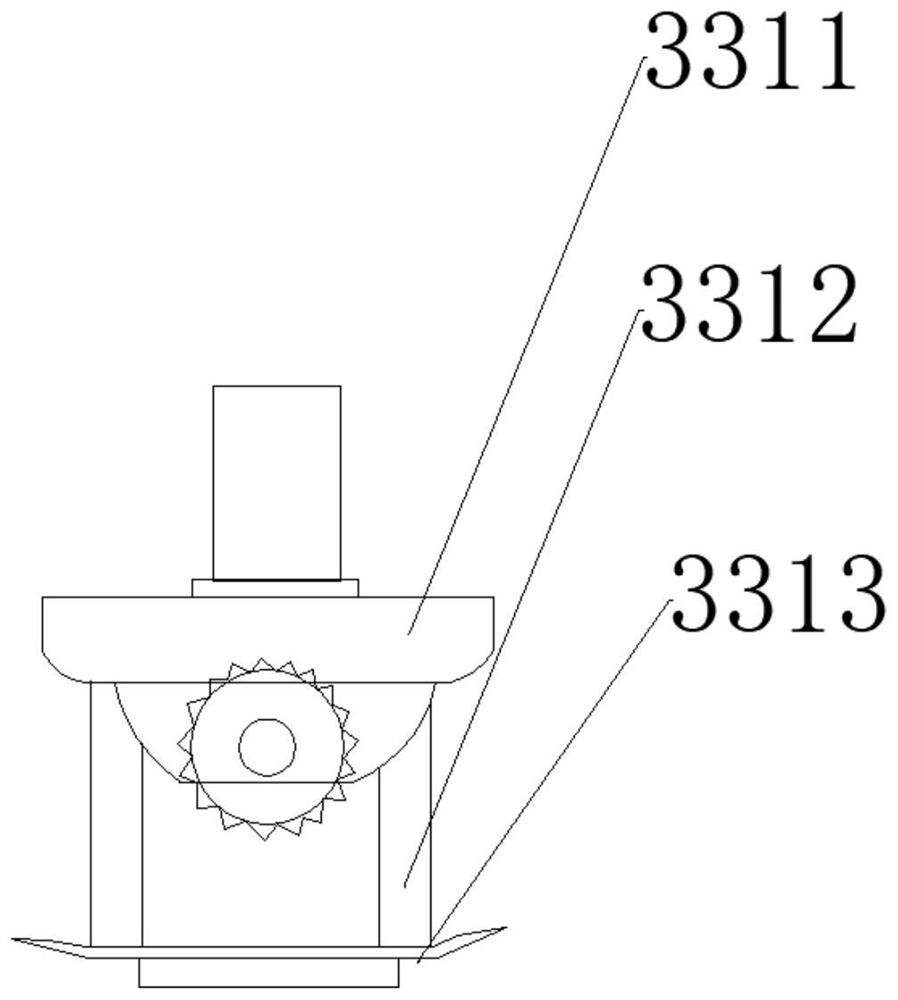

[0045] As shown in the figure, a tempered glass high-temperature continuous baking and bending equipment includes: a working chamber 1, a first heating chamber 2, and a bending processing chamber 3, and the first heating chamber 2 and bending processing chamber 3 are both located in the working chamber 1 Inside, and the bending processing chamber 3 is arranged behind the first heating chamber 2, wherein, the bending processing chamber 3 is provided with a set of adjustable support frames 31, a set of deformation support parts 32 and a set of adsorption and shaping mechanisms 32 , the adjustable support frame 31 is arranged at the bottom of the bending processing chamber 3, the deformation support part 32 is arranged at the bottom of the bending processing chamber 3, and is arranged on both sides of the adjustable support frame 31, and the adsorption setting mechanism 32 It is located on the top of the bending processing chamber 3, and the two are connected movably.

[0046] In...

Embodiment 2

[0052] As shown in the figure, a tempered glass high-temperature continuous baking and bending equipment includes: a working chamber 1, a first heating chamber 2, and a bending processing chamber 3, and the first heating chamber 2 and bending processing chamber 3 are both located in the working chamber 1 Inside, and the bending processing chamber 3 is arranged behind the first heating chamber 2, wherein, the bending processing chamber 3 is provided with a set of adjustable support frames 31, a set of deformation support parts 32 and a set of adsorption and shaping mechanisms 32 , the adjustable support frame 31 is arranged at the bottom of the bending processing chamber 3, the deformation support part 32 is arranged at the bottom of the bending processing chamber 3, and is arranged on both sides of the adjustable support frame 31, and the adsorption setting mechanism 32 It is located on the top of the bending processing chamber 3, and the two are connected movably.

[0053] In...

Embodiment 3

[0062] As shown in the figure, a tempered glass high-temperature continuous baking and bending equipment includes: a working chamber 1, a first heating chamber 2, and a bending processing chamber 3, and the first heating chamber 2 and bending processing chamber 3 are both located in the working chamber 1 Inside, and the bending processing chamber 3 is arranged behind the first heating chamber 2, wherein, the bending processing chamber 3 is provided with a set of adjustable support frames 31, a set of deformation support parts 32 and a set of adsorption and shaping mechanisms 32 , the adjustable support frame 31 is arranged at the bottom of the bending processing chamber 3, the deformation support part 32 is arranged at the bottom of the bending processing chamber 3, and is arranged on both sides of the adjustable support frame 31, and the adsorption setting mechanism 32 It is located on the top of the bending processing chamber 3, and the two are connected movably.

[0063]In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com