Light source shaping and adjusting system

A technology for adjusting the system and light source, applied in optics, optical components, instruments, etc., can solve the problems of loss of light source, low brightness of light source, etc., achieve the effect of parallel light, improve light quality, and increase light source brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-5 The application is described in further detail.

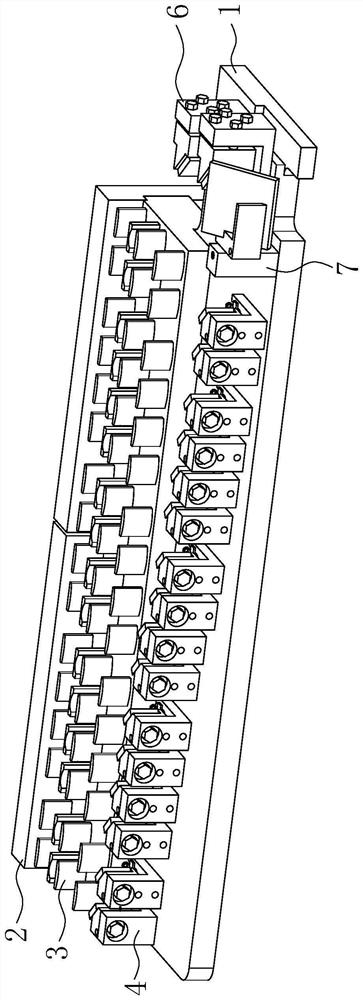

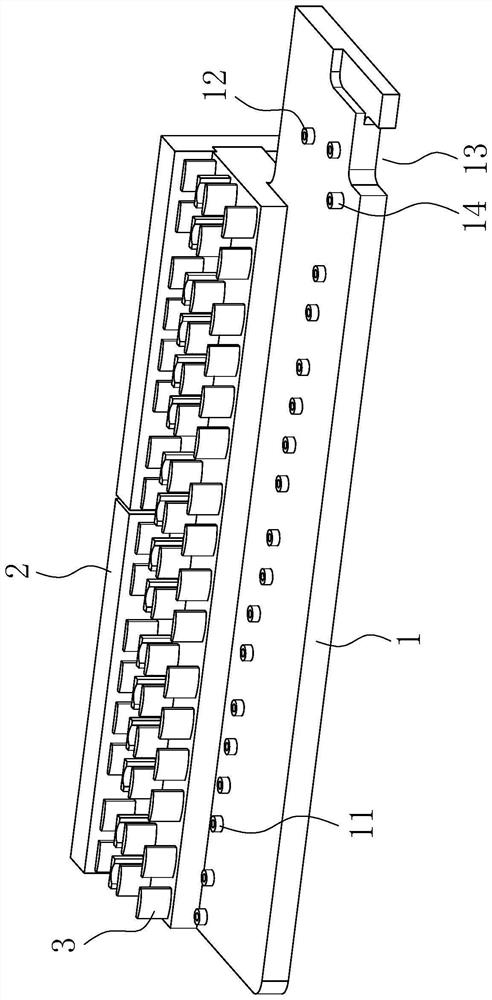

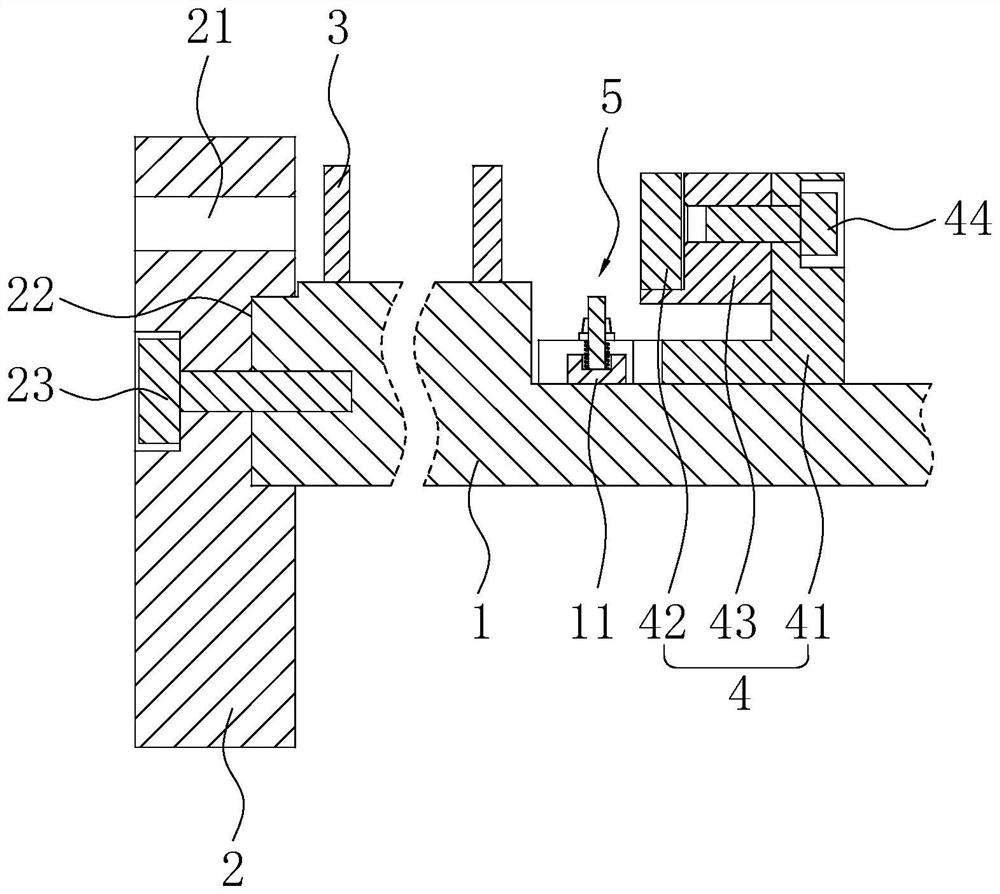

[0037] The embodiment of the present application discloses a light source shaping and adjusting system. refer to figure 1 , The light source shaping and adjusting system includes a workbench 1, a light source launching platform 2, a first adjustment seat 4, a second adjustment seat 6, and a third adjustment seat 7.

[0038] refer to figure 1 and figure 2 , the back side of the upper surface of the workbench 1 is fixed with multiple groups of plastic lenses 3 evenly arranged from left to right, and the front side of the upper surface of the workbench 1 is fixed with a plurality of first limiting columns 11 arranged obliquely from left to right and forward , the number of the first limiting columns 11 is the same as the number of groups of the plastic lens 3 and the left and right positions are opposite, and the front side of the workbench 1 is fixed with two second limiting colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com