Climbing operation maintenance platform for comprehensive distribution box

A technology for overhauling platforms and distribution boxes, applied in electrical components, switchgear and other directions, can solve the problems of low work efficiency, troublesome maintenance personnel carrying climbing tools, and high installation height, and achieve the effect of improving safety and saving manpower and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

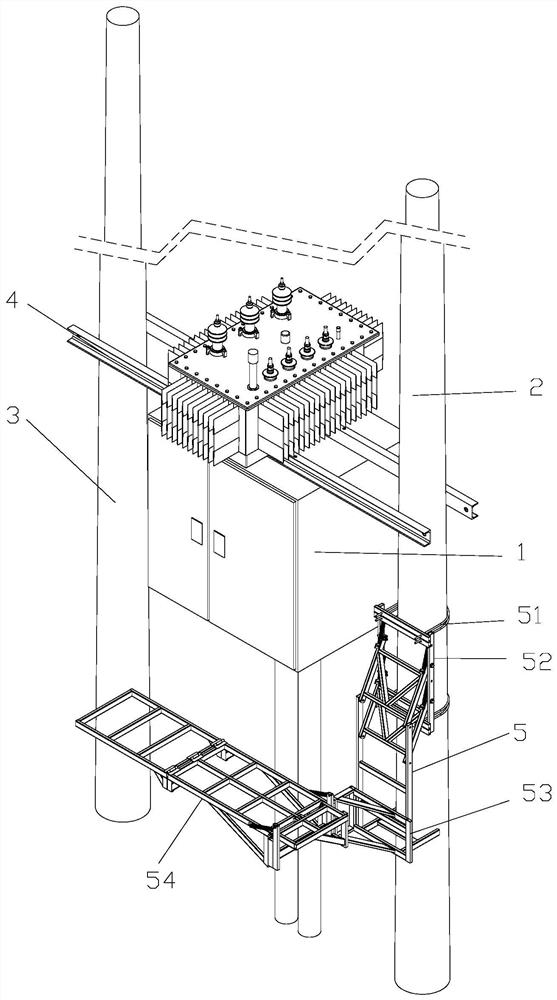

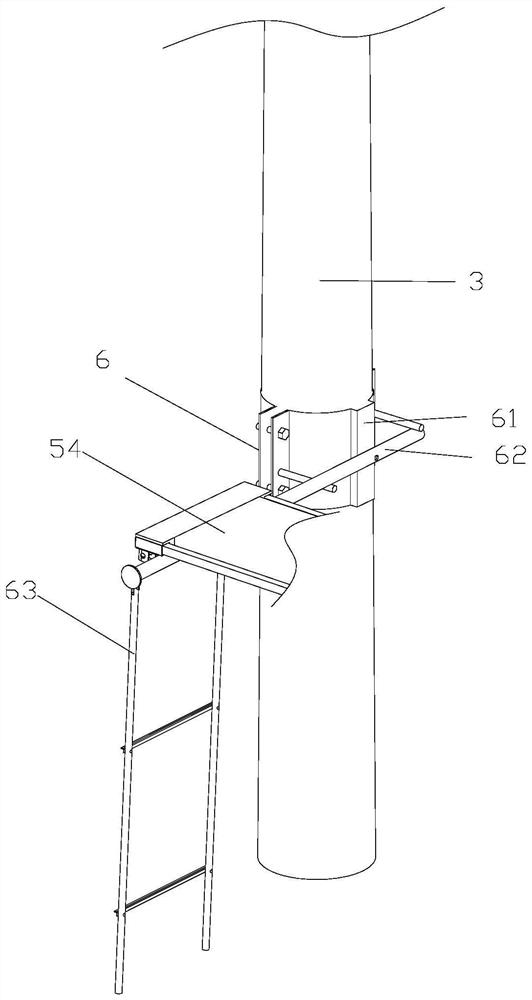

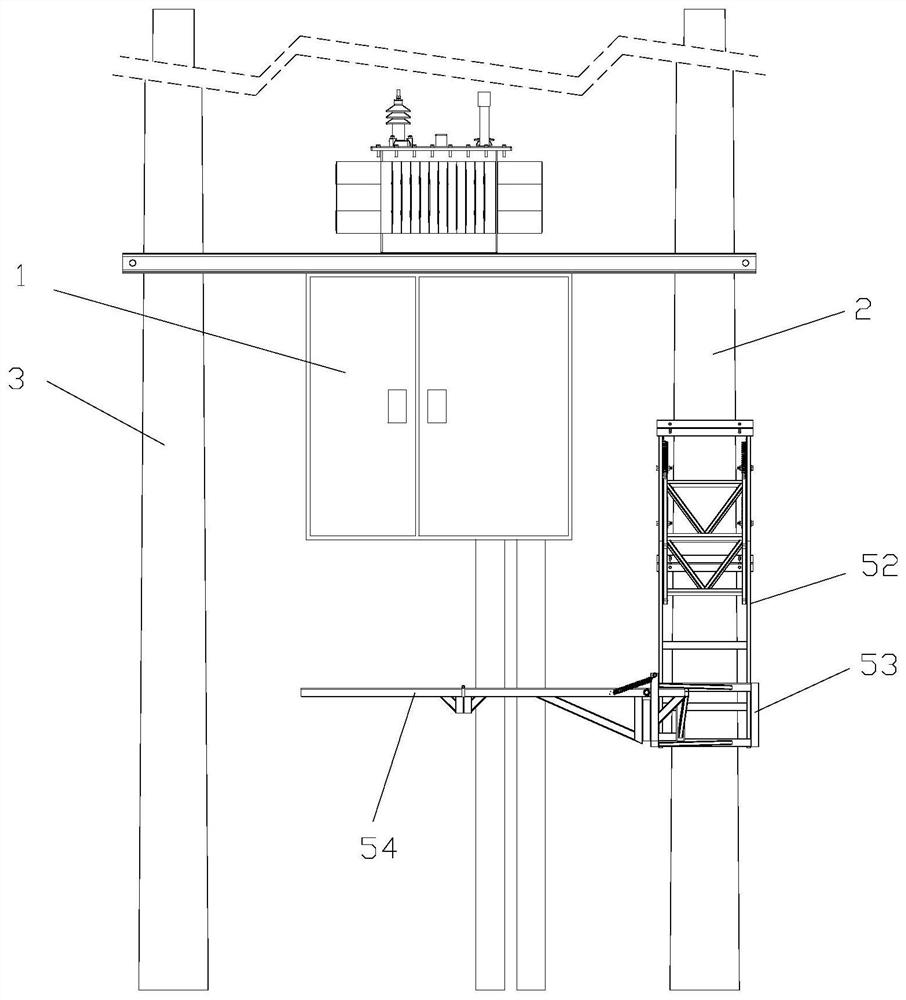

[0040] The present invention as Figure 1-6 As shown, the distribution box 1 is arranged on the cross arm 4 between the first pole 2 and the second pole 3, and the first pole is parallel to the second pole; the maintenance platform includes a platform assembly 5 and auxiliary supports component 6,

[0041] The platform assembly 5 is arranged on the pole one 2, and the platform assembly 5 includes a pair of upper support group 51, lifting group 52, lower support group 53 and telescopic platform 54 arranged up and down;

[0042] The upper support group 51 includes a hoop 511 and a cross bar 512, the hoop is U-shaped, a pair of perforations are provided on the cross bar, the pole is located in the hoop, and the two ends of the hoop have External threads, the two ends of the hoop respectively pass through a pair of through holes of the cross bar and connect with nuts;

[0043] The lifting group 52 includes a pair of parallel upper links 521 and a pair of parallel lower links 522...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com