Pillow type packaging machine cleaning device and cleaning method thereof

A technology of pillow packaging machine and cleaning device, which is applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., and can solve problems such as the inability to realize the filling production of low-temperature live fungus products and the lack of CIP cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

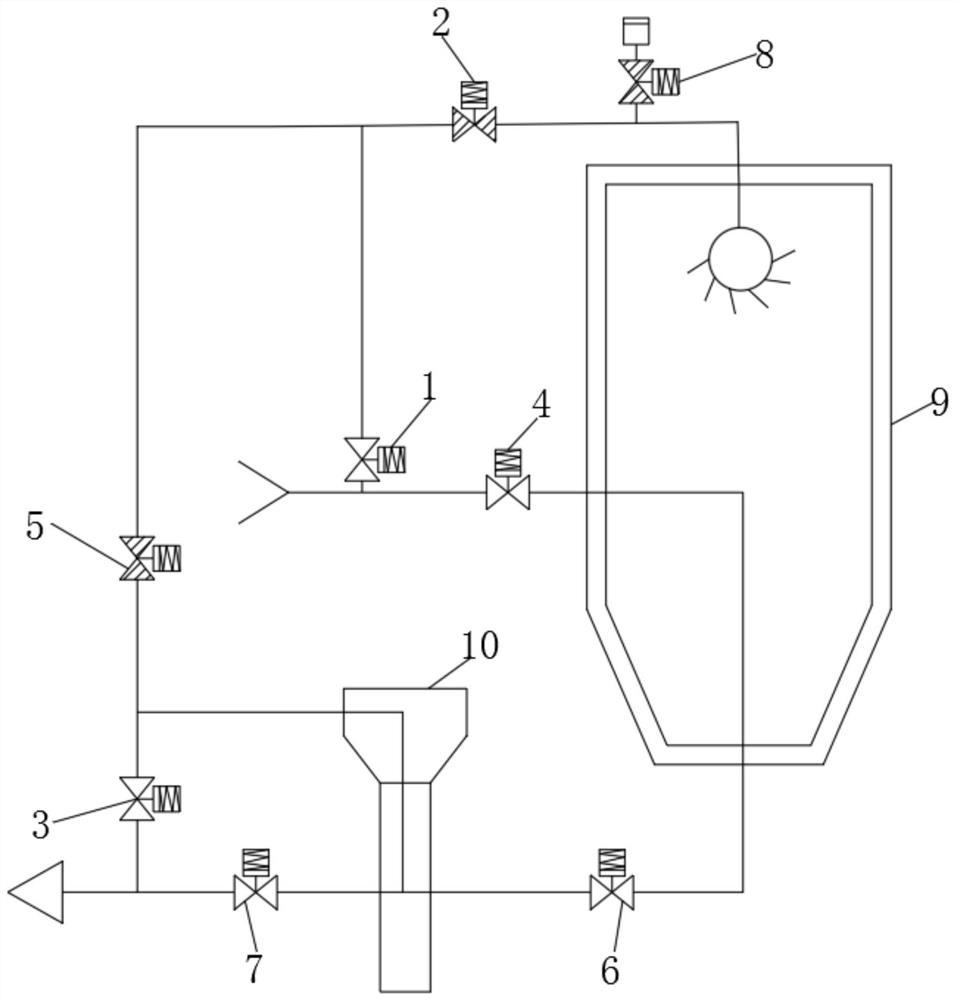

[0027] like figure 1 Shown: a pillow packaging machine cleaning device, including: a first tank 9 and a second tank 10, the top of the first tank 9 runs through a pipeline, and the pipeline communicates with a breathing cap 8 and a spray head 2, The spray head 2 is connected with the CIP main valve 1 through the pipeline, the CIP main valve 1 is connected with the feed valve 4 through the pipeline, the bottom of the first tank body 9 is connected with the piston inlet valve 6 through the pipeline, and the spray head 2 is connected with the feed valve 4 through the pipeline. Positive flushing valve 5, positive flushing valve 5 is connected with backflush valve 3 through pipeline, backflush valve 3 is connected with piston outlet valve 7 through pipeline, piston inlet valve 6 is connected with piston outlet valve 7 through pipeline, and feed valve 4 is connected with piston outlet valve 7 through pipeline. The inlet valve 6 is communicated with the pipeline, and the breathing ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com