Rubber tire processing technology

A technology of rubber tires and processing technology, applied in the field of rubber tire manufacturing and processing, can solve the problems of high risk of manual hand-held scrapers, inability to completely scrape burrs, and hidden dangers of operation safety, so as to improve the efficiency of burr scraping and improve efficiency , Reduce the effect of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

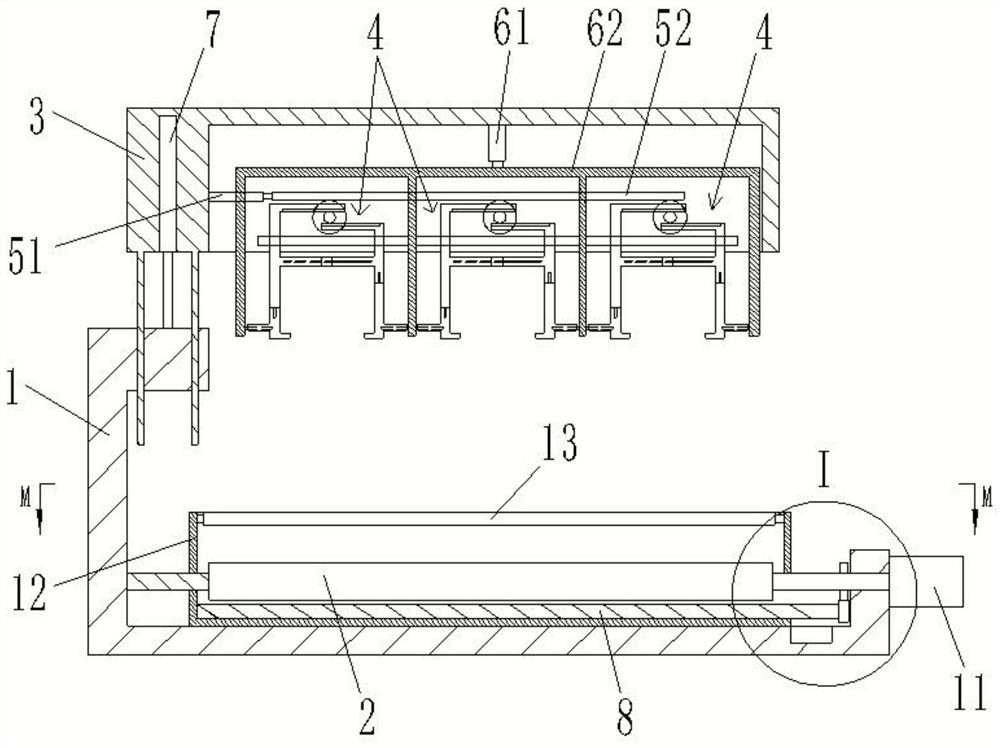

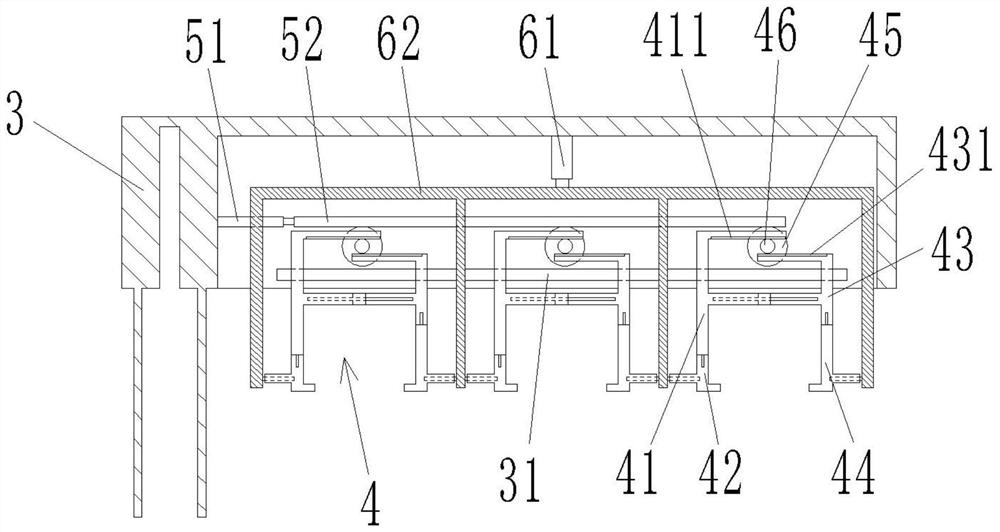

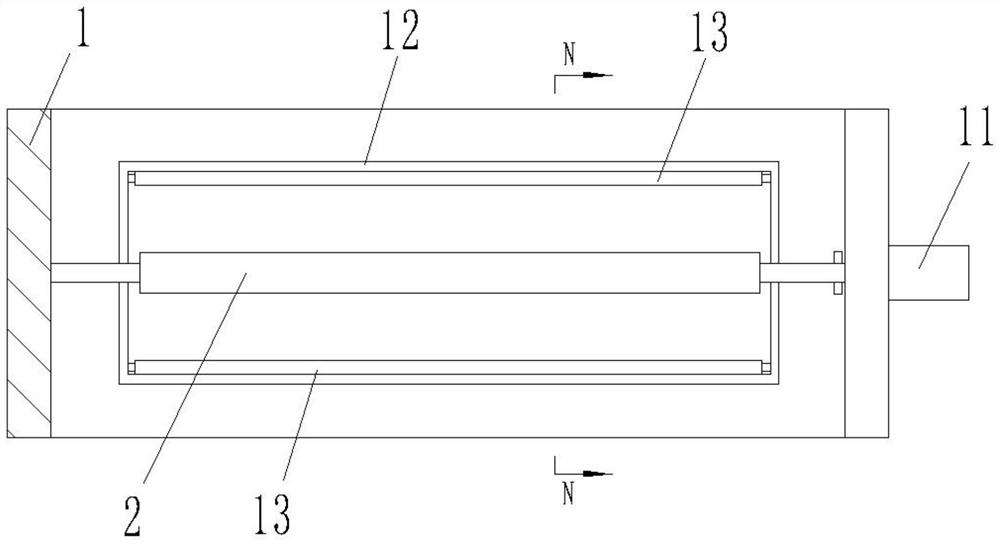

[0028] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] When adopting the rubber tire processing technology of the present embodiment to carry out the deburring operation to the rubber tire, the following steps are included:

[0030] Step S1, placing the rubber tire. Put the rubber tire to be processed vertically on the driving wheel, so that the outer circumferential surface of the rubber tire is in sliding contact with the surface of the driving wheel.

[0031] Step S2, adjusting the position of the scraper. The scraper for scraping off the burrs on the rubber tire is placed on the surface of the rubber tire, including the outer circumferential surface, two side surfaces and the inner ring surface of the rubber tire.

[0032] Step S3, scraping off the burrs on the rubber tire. The rubber tire is driven to rotate by the driving wheel, and the burrs on the rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com