Automatic temperature control device for mass concrete

A mass concrete, automatic temperature control technology, applied in the field of concrete equipment, can solve the problems of increasing material cost, high use time requirements, changing concrete properties, etc., to achieve the effect of reducing equipment manufacturing costs, construction costs, and stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

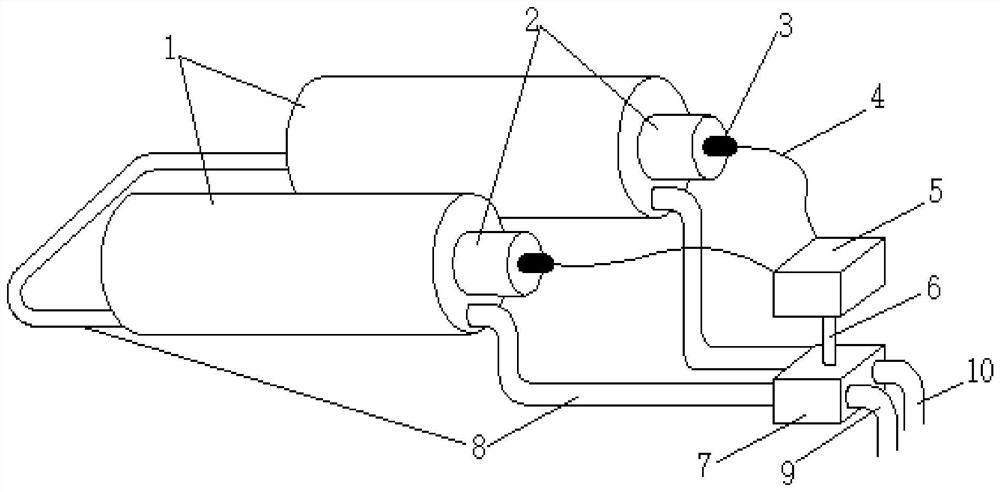

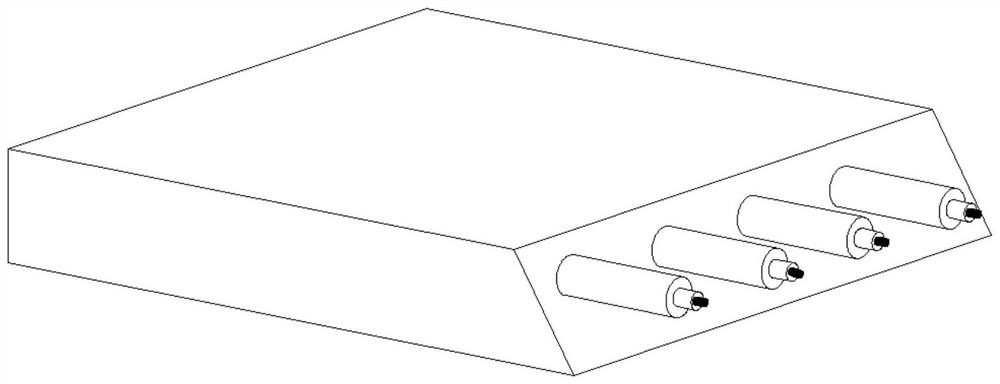

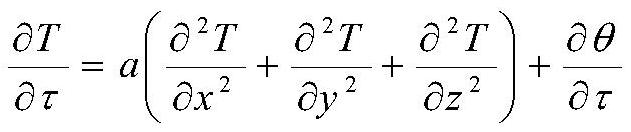

[0020] In order to solve the problem that the concrete cannot be automatically controlled during the concrete pouring and curing process, the embodiment of the present invention provides an automatic temperature control device suitable for large-volume concrete, which consists of a water cooling system main body, a temperature control system, and a transmission structure. Partial composition.

[0021] The main body of the water cooling system includes a pressure-resistant steel pipe 1, a PVC riser 2 and a temperature sensing element 3 arranged inside the pressure-resistant steel pipe 1; a closed medium chamber is formed between the pressure-resistant steel pipe 1 and the PVC riser 2, and the medium chamber is water-cooled. medium (temperature control medium), the temperature sensing element 3 is inside the PVC water riser 2 . Among them, the pressure-resistant steel pipe 1 is used to protect the PVC water riser 2 from being crushed by concrete gravity and concrete expansion de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com