Steel structure anti-corrosion device

A technology of anti-corrosion device and steel structure, applied in the direction of coating, metal material coating process, hot-dip plating process, etc., can solve the problems of excessive zinc slag and easy corrosion, and achieve the effect of increasing the collection space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] as attached figure 1 To attach Figure 7 Shown:

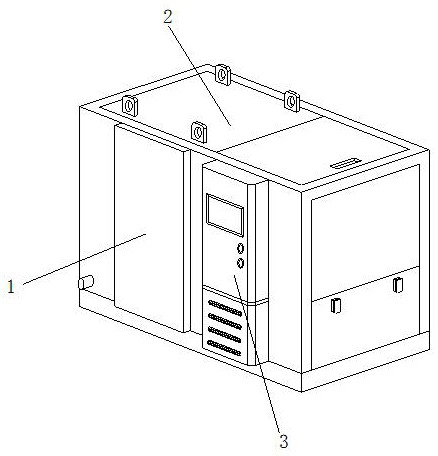

[0029] The invention provides a steel structure anticorrosion device, the structure of which includes: a door leaf 1, a box body 2, and a control terminal 3. The door leaf 1 is installed in front of the box body 2 through a hinge connection, and a control terminal End 3.

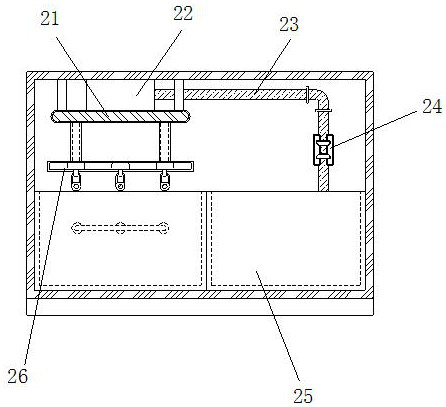

[0030] Wherein, the box body 2 includes a drive plate 21, an inner cavity 22, a connecting pipe 23, a mounting plate 24, an active cavity 25, and a connecting plate 26, and the lower end surface of the driving plate 21 is welded to the upper end surface of the connecting plate 26, so that The inner cavity 22 is installed on the inner side of the box body 2, the connecting pipe 23 is fixed in the box body 2 through the mounting plate 24, and the lower end of the connecting pipe 23 is embedded in the inner side of the movable chamber 25, and the movable chamber 25 is detachably installed inside the box 2.

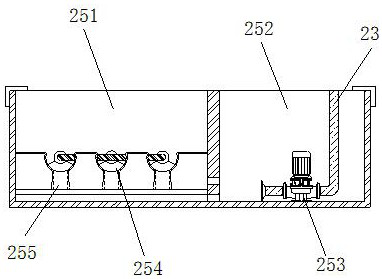

[0031] Wherein, the movable chamber 25 inc...

Embodiment 2

[0039] as attached Figure 8 to attach Figure 9 Shown:

[0040] The present invention provides a steel structure anticorrosion device. The collecting device 255 includes a drain port 551, a moving mechanism 552, a fixed cavity 553, an inner bucket 554, and a base 555. The drain port 551 and the base 555 are an integrated structure. The moving The mechanism 552 is installed inside the fixed cavity 553. The lower end surface of the inner barrel 554 is embedded and connected with the upper end surface of the base 555. The fixed cavity 553 is fitted with the swing block 544, so that the zinc liquid is collected when it is not discharged. The device 255 is in a closed state to prevent liquid zinc from flowing into the collection device 255. The base 555 and the fixed chamber 553 are cylindrically telescopic, so the inner barrel 554 will move downward under the accumulation gravity of the zinc slag, thereby increasing the collection capacity. space, and the base 555 and the fixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap