Heater integrated gas chromatography column device

A gas chromatography and heater technology, which is applied in the field of heater integrated gas chromatography column devices, can solve the problems of difficult temperature gradient, reduce temperature response time, increase, etc., and achieve the effects of steep temperature gradient, reduced measurement time, and excellent resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

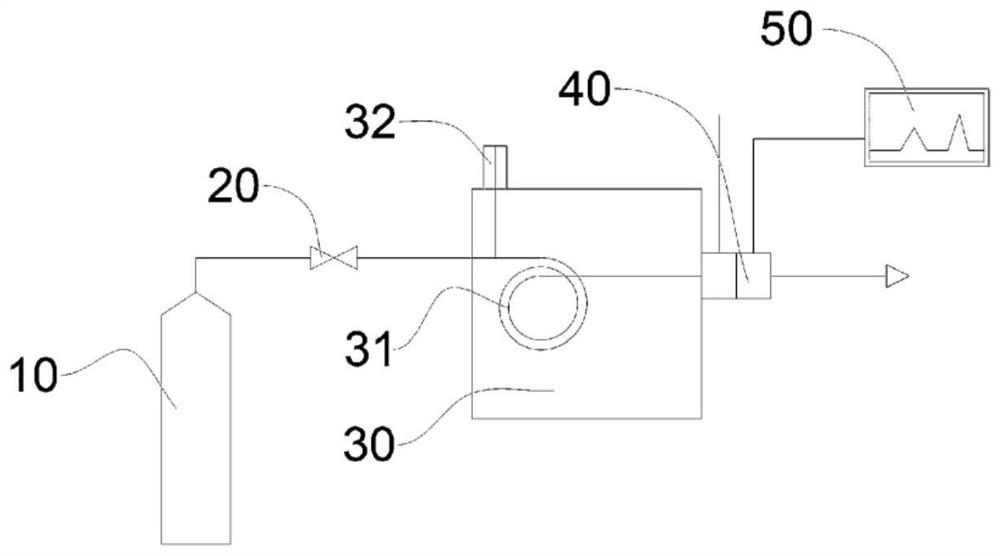

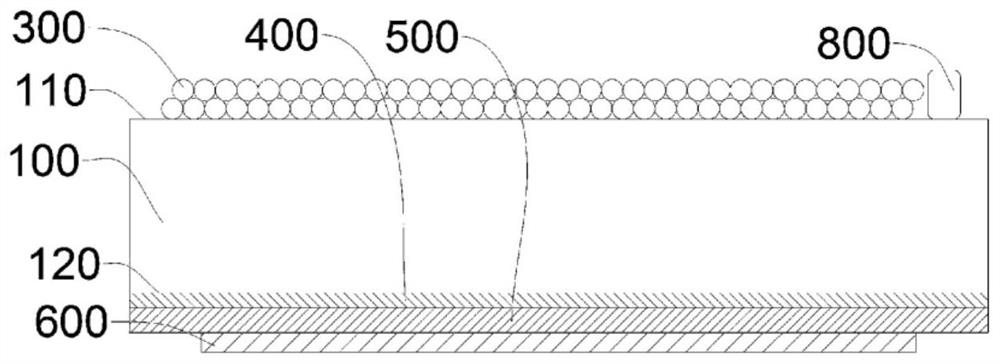

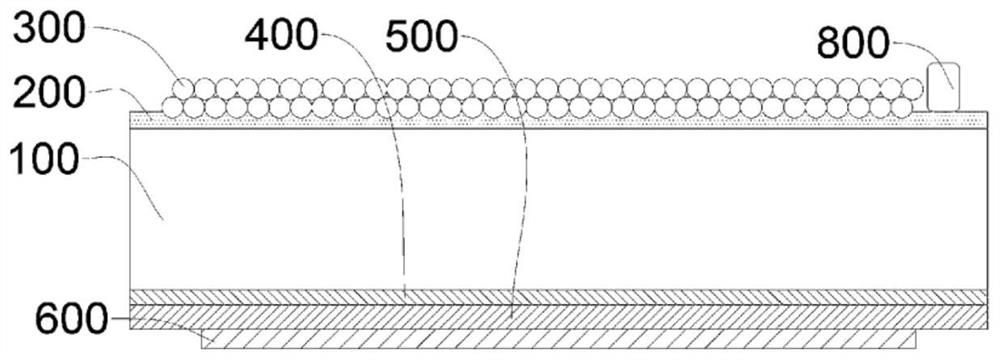

[0051] Hereinafter, a heater-integrated gas chromatography (GC) column device according to the present invention will be described in detail with reference to the accompanying drawings.

[0052] The drawings of the present invention are provided by way of example so that the spirit of the present invention can be fully conveyed to those skilled in the art. Therefore, the present invention is not limited to the drawings but can be modified in many different forms. Also, the drawings may be exaggerated to clarify the spirit and scope of the present invention.

[0053] Unless otherwise defined, the technical terms and scientific terms used in the present invention have the ordinary meanings understood by those skilled in the art to which the present invention belongs, and conventional terms that unnecessarily obscure the gist of the present invention will be omitted in the following description and drawings. Descriptions of known functions and configurations.

[0054] Unless th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com