Gasifier fluid setscrew

A technology for adjusting screws and carburetors, used in carburetors, machines/engines, lift valves, etc., can solve the problems that the carburetor cannot be miniaturized, cannot maintain concentricity, and cannot supply low-speed mixed gas normally and uniformly. , to achieve the effect of precise and uniform adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

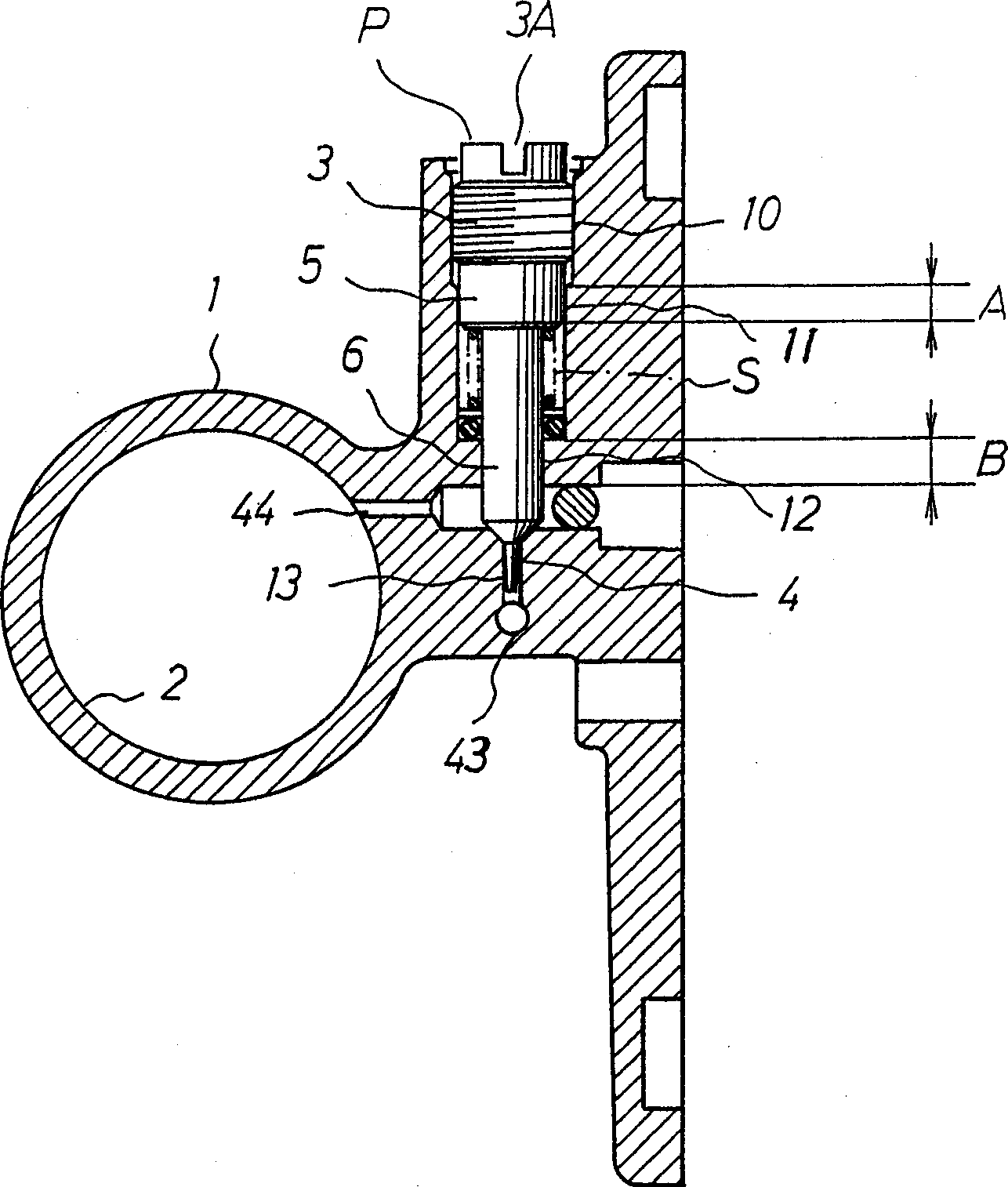

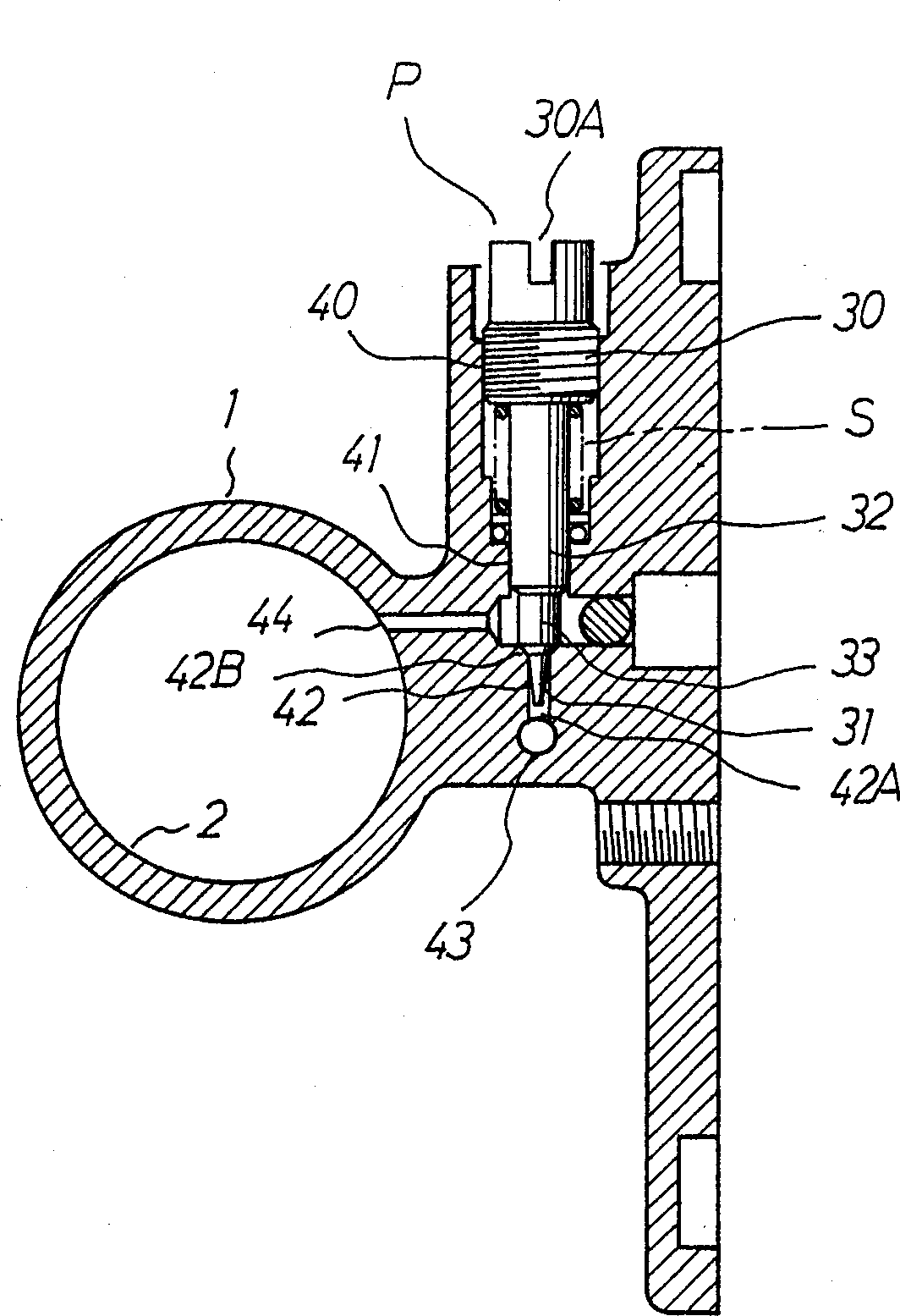

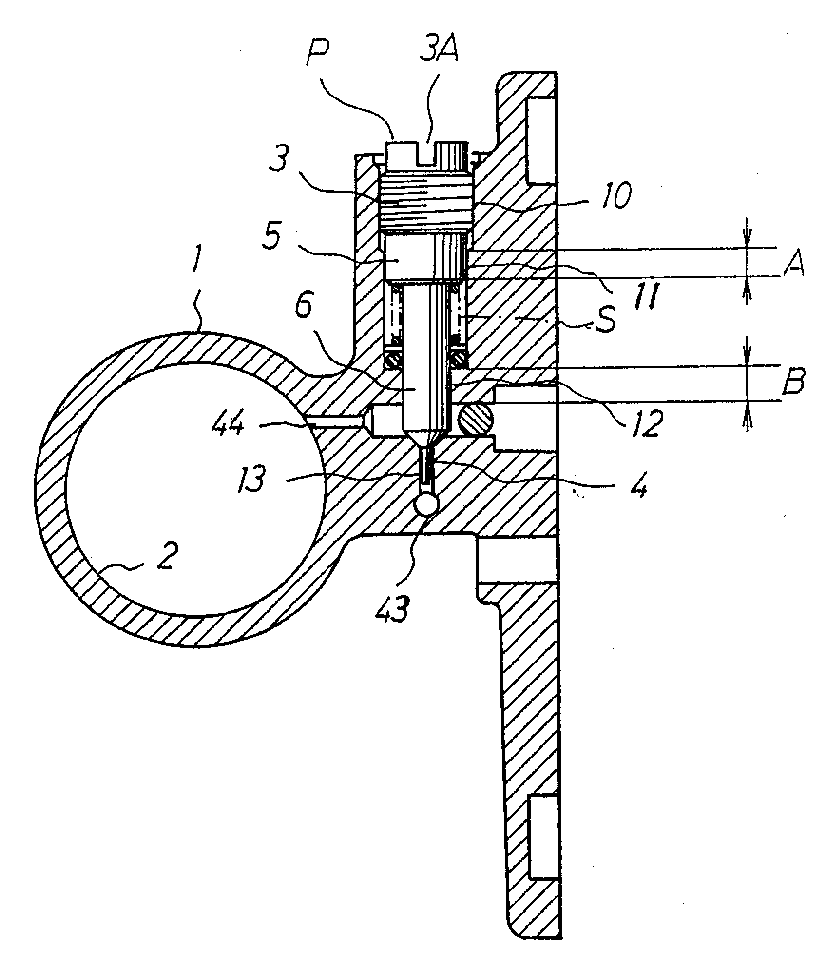

[0026] Below, combine figure 1 One embodiment of the fluid adjustment screw of the present invention will be described.

[0027] The fluid controller of this embodiment is the same vaporizer as the embodiment in the prior art, and the same structural parts are denoted by the same numbers.

[0028] 1 is the carburetor body which is installed inside and runs through the suction passage 2.

[0029] P is a fluid adjustment screw, which in this embodiment is the main control screw for adjusting the low-speed mixed gas volume.

[0030] Fluid adjustment screw P consists of the following parts:

[0031] 3 is a threaded part arranged at its rear end, and an adjustment groove 3A of inline shape, cross shape, etc. is set on its rear end surface;

[0032] 4 is a conical needle valve part arranged at its front end, and the threaded part 3 and the conical needle valve part 4 are connected in such a way that a large-diameter guide cylinder part 5 is sequentially arranged in succession to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com