Grain storage simulating device and method with precise temperature control

A technology of precise temperature control and simulation device, which is applied in fruit suspension devices, botanical equipment and methods, food preservation, etc. problems, to achieve the effect of convenient maintenance, uniform distribution, and efficient heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

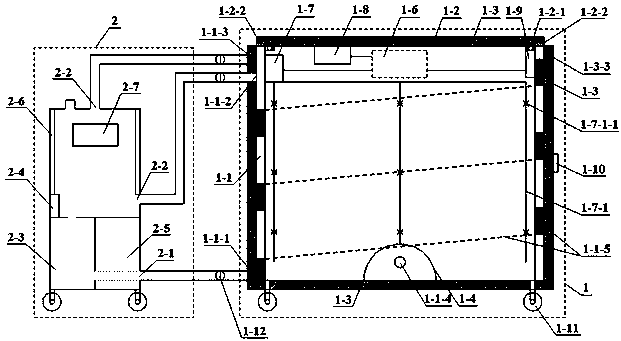

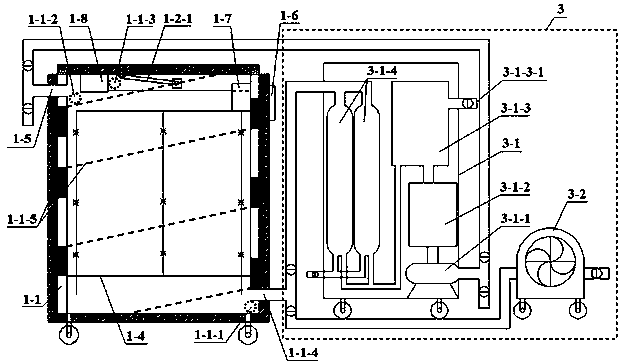

[0059] Such as Figure 1~5 As shown, the device includes a bin body 1, a liquid refrigerant temperature control unit 2 and an air control unit 3; the bin wall of the bin body 1 is provided with a 1 cm thick temperature control layer 1-1 (length 1.5m, width 1.0 m, height 1.3m), the top of the warehouse body 1 is provided with a movable top cover 1-2, and the bottom of the warehouse body 1, the temperature control layer 1-1 and the movable top cover 1-2 are provided with an insulation layer 1-3 ; The outer side of the lower end of the temperature control layer 1-1 is provided with a water inlet 1-1-1, which is connected with the water outlet 2-1 of the liquid refrigerant temperature control unit 2; The water outlet 1-1-2 and the overflow outlet 1-1-3 are respectively connected to the water inlet 2-2 of the liquid refrigerant temperature control unit 2; the inside center of the bottom of the warehouse body 1 is provided with an above-ground cage 1-4 (length 1m , 0.4m in width an...

Embodiment 2

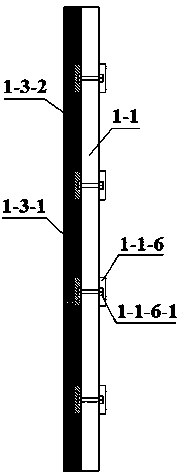

[0066] The difference between the embodiment of the present invention and embodiment 1 is only: as Figure 6 As shown, the diversion mechanism 1-1-5 is parallel to the bottom surface of the warehouse body 1, and the diversion mechanism 1-1-5 divides the temperature control layer 1-1 into 3 layers, and is provided with a water inlet 1-1 -1. In the temperature control layer 1-1 on the side of the water outlet 1-1-2 and the overflow 1-1-3, there is also a continuous and longitudinal "S"-shaped flow guide mechanism 1-1-5 , the arc-shaped outer sides of the uppermost and lower ends of the "S"-shaped flow guide mechanism 1-1-5 are respectively facing the water outlet 1-1-2 and the water inlet 1-1-1, and the horizontal flow guide mechanism 1-1- 5 is connected to the outside of each arc, and the horizontal diversion mechanism 1-1-5 is 20cm away from the inner side of each arc; the upper and lower arcs of the "S"-shaped diversion mechanism 1-1-5 are tangent, and the arc The radius is ...

Embodiment 3

[0069] The difference between the embodiment of the present invention and embodiment 1 is only: as Figure 7 As shown, in the temperature control layer 1-1 on the side of the water inlet 1-1-1, the water outlet 1-1-2 and the overflow 1-1-3, the flow guide mechanism 1-1 of each adjacent layer -5 are parallel to each other, and form 23.4° with the bottom surface of the warehouse body 1, the vertical distance between the diversion mechanisms 1-1-5 of adjacent layers is equal and 39.8cm, and the temperature control layer 1-1 on the other three sides The inside extends parallel to the bottom surface of the warehouse body 1 . The rest are the same as embodiment 1.

[0070] After testing, the device of the present invention can regulate the temperature of the warehouse wall and precisely control the temperature of the warehouse body, and the design in terms of heat preservation, temperature control, and uniform temperature makes the temperature control accuracy reach ±0.1°C.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com