Seedling raising device for flower seedlings

A seedling raising device and technology for seedlings, applied to parts of planters, machinery for interval-type quantitative sowing, etc., can solve problems such as low efficiency of on-demand sowing, uneven seeds, high labor intensity, etc., to improve the quality and speed of sowing, and control the quantity , sowing uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

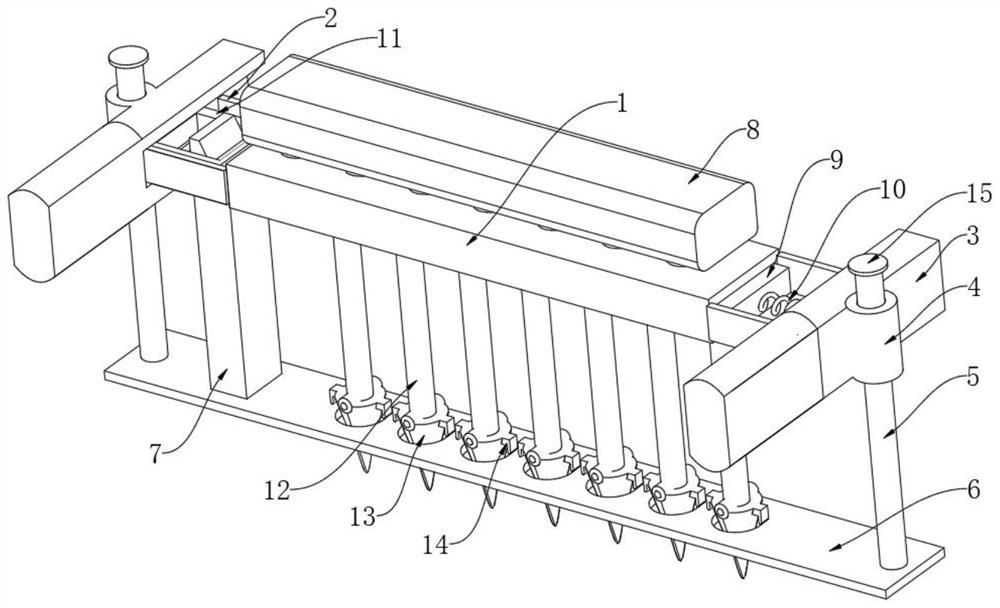

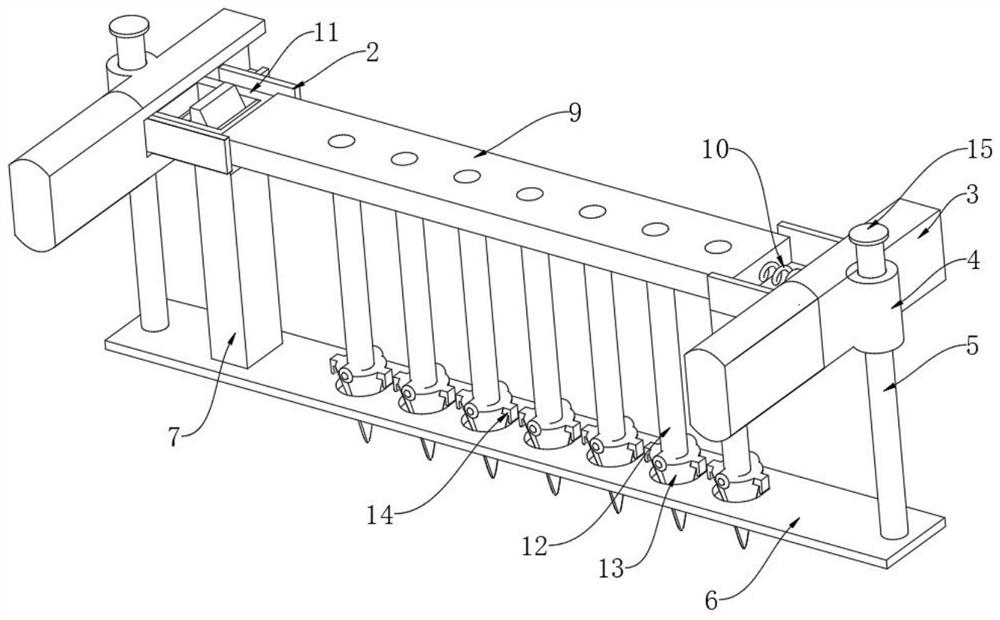

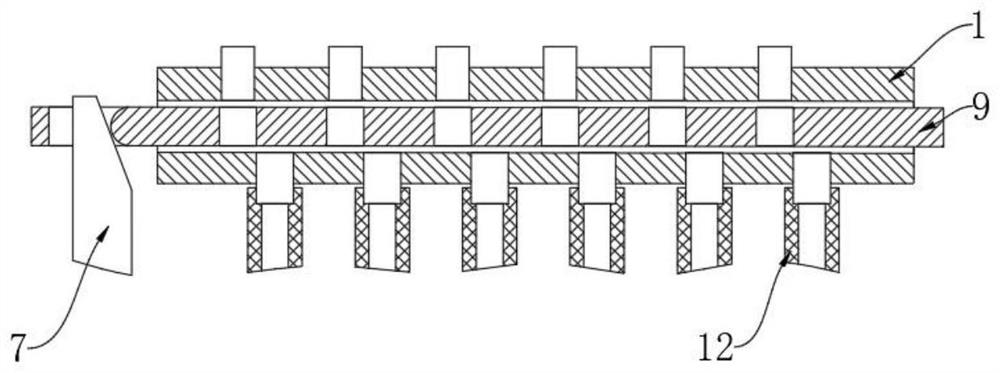

[0026] refer to Figure 1-4 , a seedling raising device for flower seedlings, comprising a sorting mechanism and a soil covering mechanism, the sorting mechanism includes an outer shell 1, the two ends of the outer shell 1 are fixedly connected with a clamping plate 2, and the surface of the clamping plate 2 is clamped with a handle The number of rods 3 and handle rods 3 is two, and the opposite surfaces of the two handle rods 3 are provided with T-shaped chute, and the clamping plate 2 is adapted to the inner wall of the T-shaped chute.

[0027] The side of the handle bar 3 is fixedly connected with a connecting sleeve 4, the inner wall of the connecting sleeve 4 is slidingly connected with a guide rod 5, the top of the guide rod 5 is provided with a threaded hole, the inner wall of the threaded hole is threadedly connected with a limit cap 15, and the bottom of the guide rod 5 The end is fixedly connected with a bottom plate 6, the upper surface of the bottom plate 6 is fixe...

Embodiment 2

[0032] refer to Figure 5-6 , the difference from embodiment 1 is that the side of the seed box 8 is provided with a rectangular chute, the inner wall of the rectangular chute is slidably connected with a screed plate 16, and the upper surface of the screed plate 16 is threadedly connected with a connecting bolt 17, and the connecting bolt 17 The threaded end of the threaded end is threadedly connected with the upper surface of the movable plate 9, because the leveling plate 16 automatically slides left and right with the movable plate 9, and the upper surface of the leveling plate 16 is provided with a through hole, and the seeds in the seed box 8 automatically pass through the through hole. Fall in movable plate 9, the lower surface of base plate 6 is connected with lifting plate 18 by bolt rotation, and the distance of lifting plate 18 and base plate 6 is adjustable, controls the depth that soil inserter 13 inserts in the soil.

[0033] In this embodiment, the movable plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com