A ceramic raw material pre-homogenization equipment

A ceramic raw material, pre-homogenization technology, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve the problems of poor uniform mixing effect and singleness, and achieve sufficient mixing and improve mixing and homogenization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

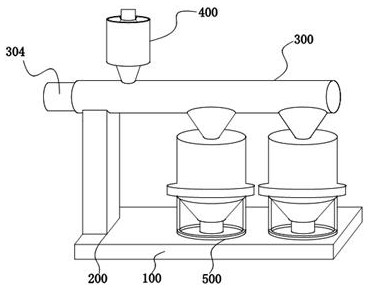

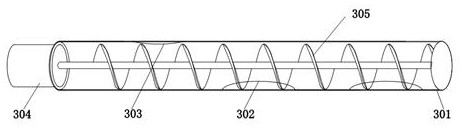

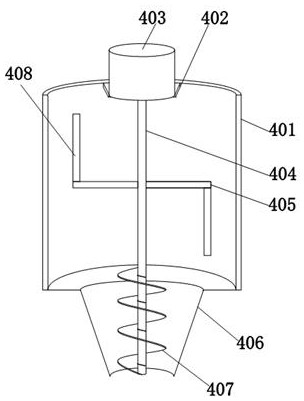

[0032] A ceramic raw material pre-homogenization equipment, such as Figures 1 to 4 As shown, it includes a support table 100, the middle part of the top left side of the support table 100 is fixedly connected with a support column 200, the top of the support column 200 is fixedly connected with a material guide device 300, and the left side of the top of the side surface of the material guide device 300 is connected with a stirring device for stirring. The unloading device 400 of the mixed ceramic raw material, and the bottom of the material guiding device 300 are connected with two fine homogenizing devices 500, and the fine homogenizing devices 500 are fixedly connected to the top of the support table 100;

[0033] The feeding device 400 includes a feeding barrel 401. A carrier plate 402 is installed above the inner cavity of the feeding barrel 401. The carrier plate 402 is fixedly connected with a servo motor 403, and the carrier plate 402 is formed with a number of feeding...

specific Embodiment approach

[0042] Firstly, the various ceramic raw materials to be mixed and homogenized are poured into the unloading bucket 401 through the unloading port of the carrier plate 402 , the servo motor 403 drives the stirring rod 405 to rotate through the rotating rod 404 , and the multiple ceramic materials placed in the unloading bucket 401 Preliminary mixing of various ceramic raw materials; since ceramic raw materials usually use natural raw materials such as feldspar, clay and quartz, which usually have a certain water absorption capacity, the ceramic raw materials are exposed to the air, and the ceramic raw materials are easy to absorb water vapor in the air. so that it is easy to adhere to the inner wall of the lowering barrel 401 during the mixing process of the lowering barrel 401; in the process that the servo motor 403 drives the rotating rod 404 to rotate, the rotating rod 404 drives the two scraping rods 408 through the stirring rod 405 to surround the rotating rod 404. Rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com