Wire drawing machining system for polypropylene plastic woven bag preparation

A polypropylene plastic and wire drawing technology, which is applied in bag making, flexible container manufacturing, paper/cardboard containers, etc., can solve the problems of easy entanglement of plastic wire drawing, inconvenient adjustment of the hole size of plastic wire drawing, etc., and achieve good sealing. effect, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

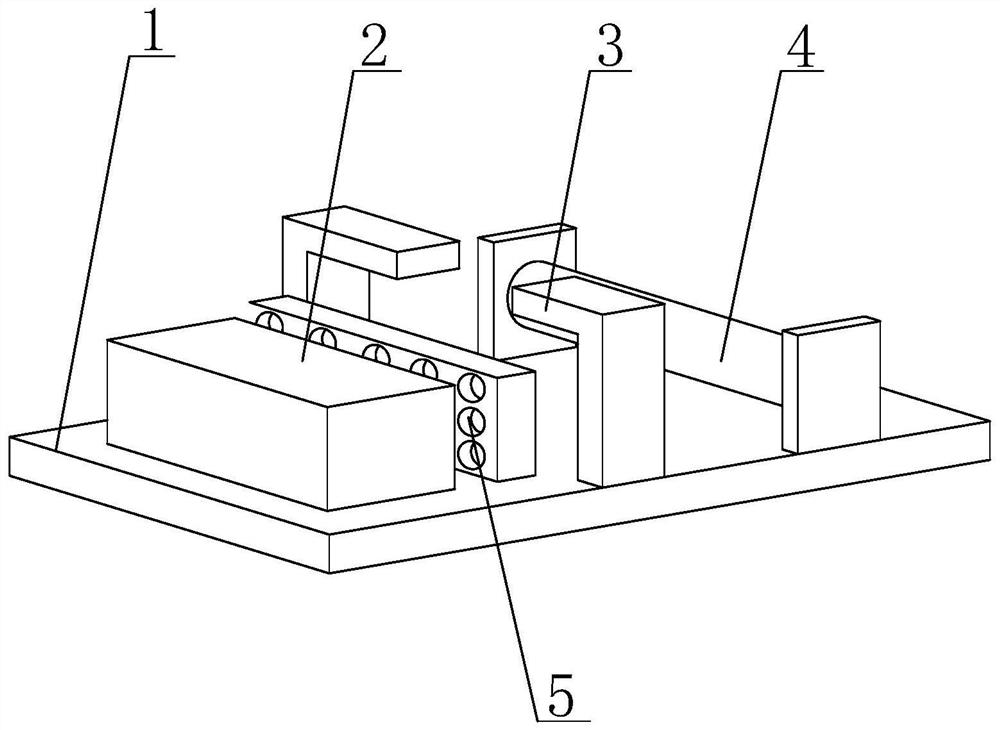

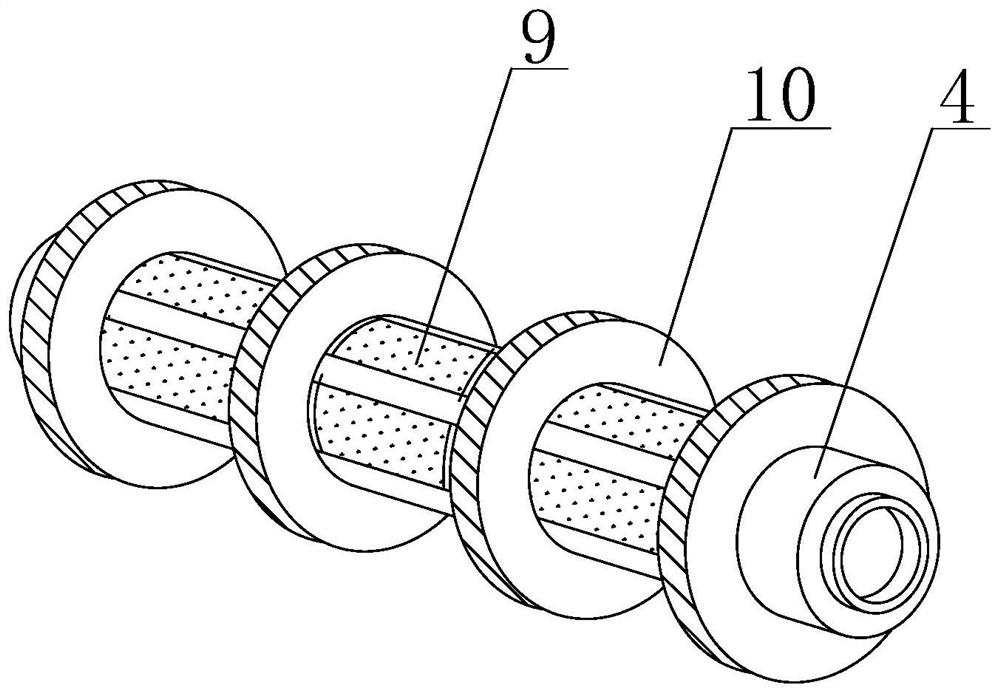

[0038] Such as Figure 1-7As shown, the present invention provides a wire drawing processing system for the preparation of polypropylene plastic woven bags, comprising a preparation processing table 1, a wire extrusion device 2 and a wire drawing reel 4, and the bottom of the wire extrusion device 2 is threaded with the top of the preparation processing table 1 connection, the wire drawing reel 4 is located on the right side of the wire extrusion device 2, and the wire drawing transition pipe 5 is arranged on the right side of the wire extrusion device 2, and the wire drawing transition pipe 5 is evenly arranged on the top of the preparation and processing table 1, and the wire drawing transition pipe 5 The right side is provided with a cooling device 3, the cooling device 3 can cool the plastic wire drawing surface, the bottom of the cooling device 3 is fixedly connected with the top of the preparation and processing table 1, and the outer wall of the wire drawing roll 4 is fi...

Embodiment 2

[0041] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a toothed baffle 17 is fixedly installed on the left side of the cooling device 3, and the toothed baffle 17 can transfer the cooling gas due to its shape. The cold air sprayed from the spray pipe 16 is evenly diffused again, so as to increase the contact area with the plastic, the inner wall of the toothed baffle 17 is embedded with a flow pipe 18, and the top of the toothed baffle 17 is provided with a cooling gas spray pipe 16. The top of the cooling gas spray pipe 16 is fixedly connected to the outer wall of the cooling device 3, the bottom of the flow pipe 18 is fixedly connected to the top of the preparation and processing table 1, and through the cooperation of the flow pipe 18, the teeth on the toothed baffle 17 are fixed. The cooling gas can circulate evenly, and the contact area between the cooling gas and the plastic wire drawing can be...

Embodiment 3

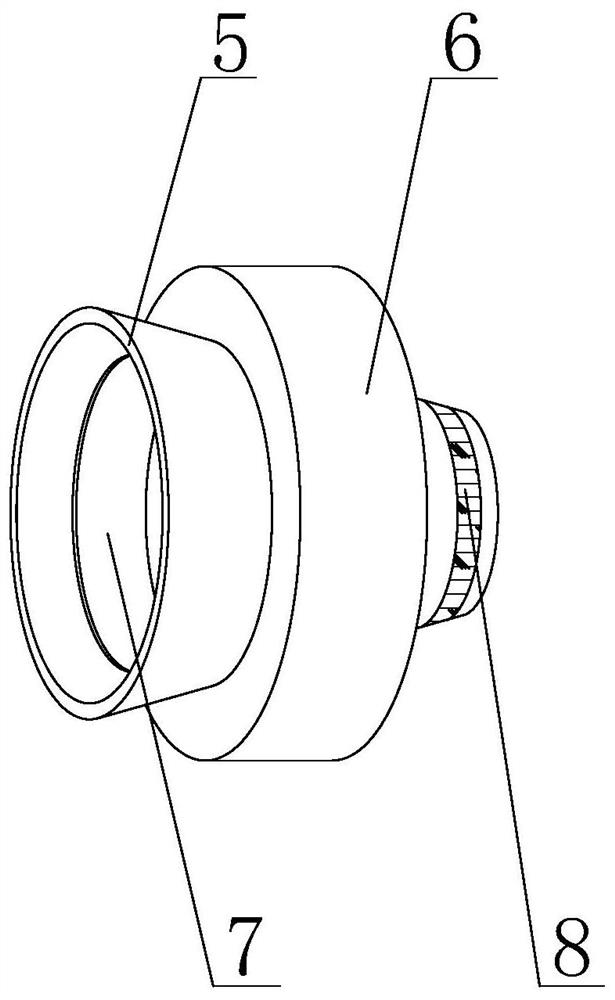

[0044] Such as Figure 1-7 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the outer wall of the wire drawing transition tube 5 is clamped with a wire heating ring 6, and the inner wall of the wire drawing transition tube 5 is fixedly installed with a heat conduction plate 7 , the output end of the wire heating ring 6 is overlapped with the inside of the heat conducting plate 7, and the right side of the wire heating ring 6 is provided with an adjustment device 8, and the inner wall side of the adjustment device 8 is clamped with the outer wall of the wire drawing transition tube 5, and the wire The heating ring 6 can transfer heat to the heat conduction plate 7, so that the surface temperature of the heat conduction plate 7 increases, which is conducive to further heat treatment of the plastic, so as to improve the adaptation effect when passing through the wire drawing transition tube 5, so that the plastic wire drawing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com