Filter module, and method for determining the state of a filter element

A filter and element technology, applied in the field of filter modules, can solve the problems of measurement system failure, excessive energy, consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

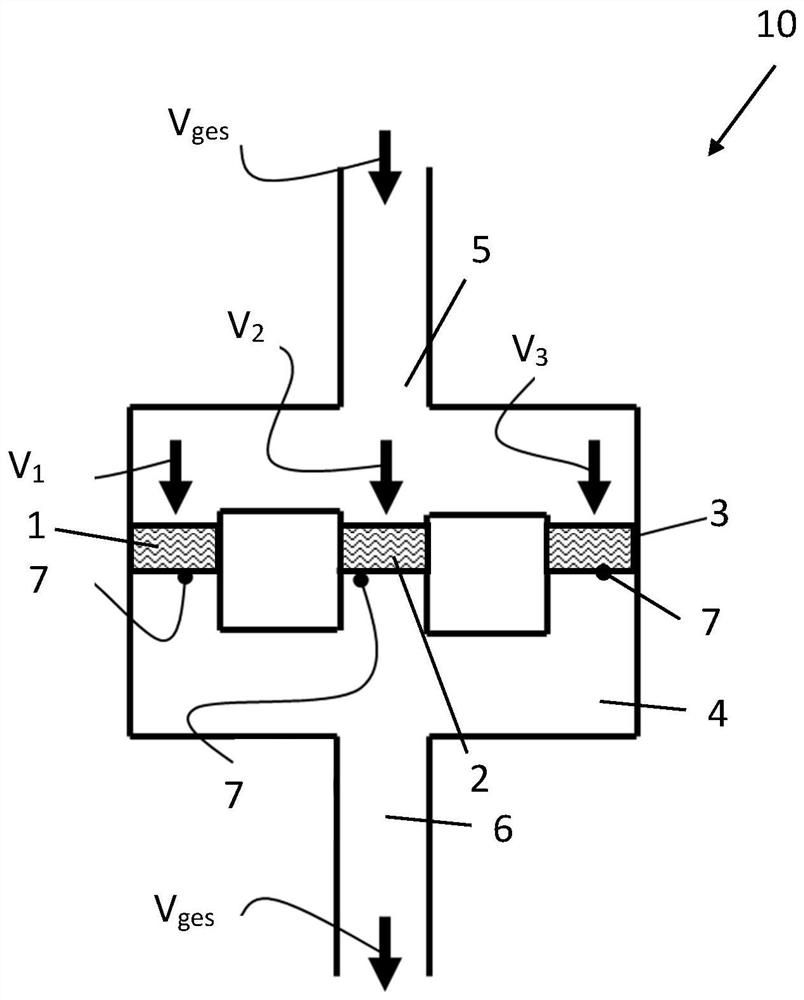

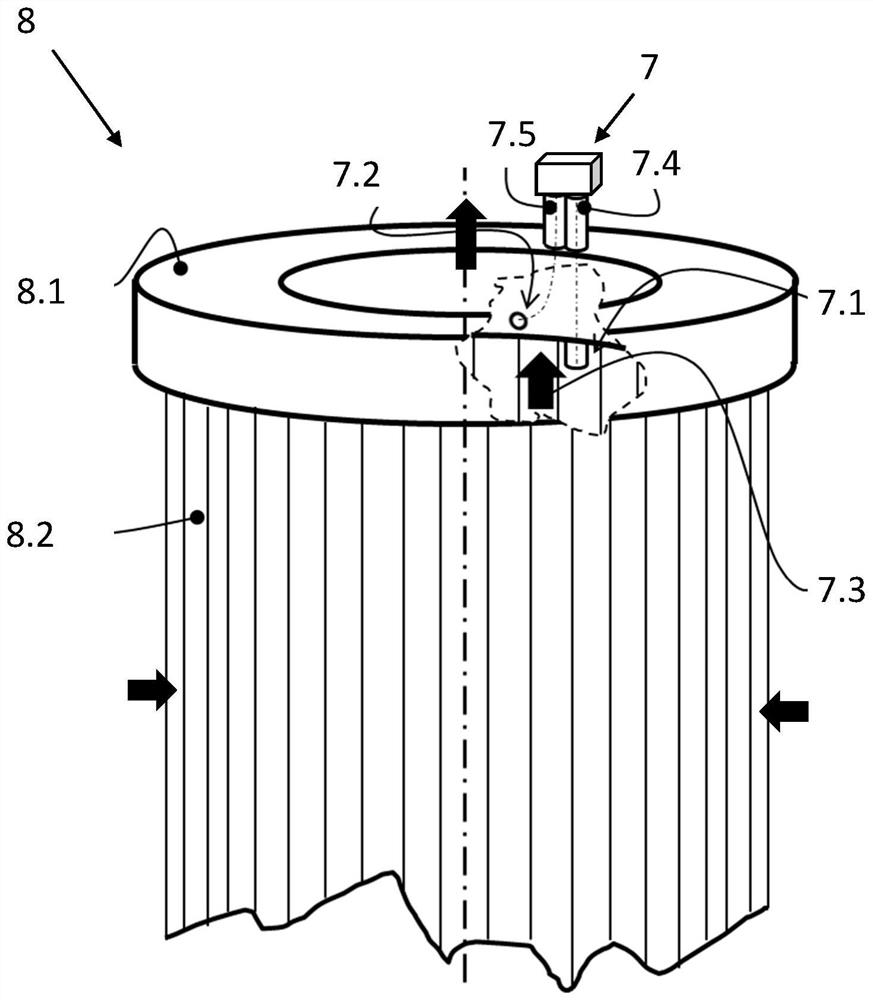

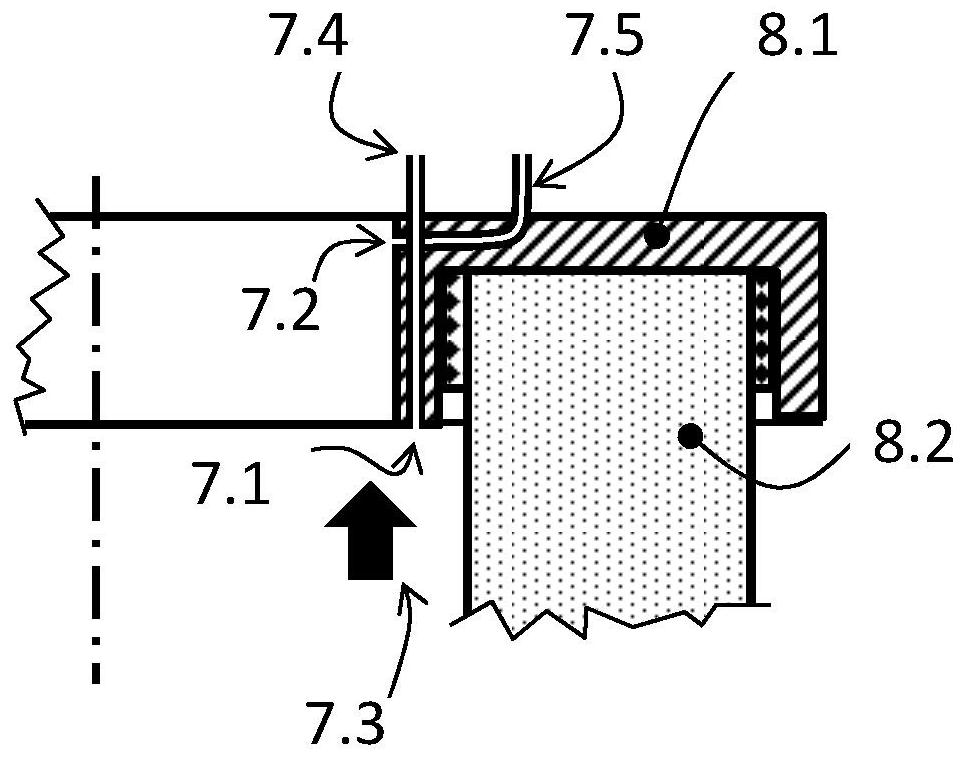

[0052] figure 1 The structure of the filter module 10 according to the invention is shown. In the air channel 4 of the filter module 10 there is a plurality of filter elements, here a first filter element 1 , a second filter element 2 and a third filter element 3 arranged in parallel connection. However, a greater number of filter elements arranged in a matrix is also conceivable. The air flows from the raw gas side 5 to the clean gas side 6 and is filtered there. A total volume flow V flows at the inlet and outlet of the filter module 10 ges . The total volume flow V ges This splits so that the first sub-volume flow V 1 Flowing through the first filter element 1, the second subvolume flow V 2 flows through the second filter element 2 and the third sub-volume flow V 3 flows through the third filter element V 3 . In order to be able to make statements about the state of the respective filter element 1 , 2 , 3 , a sensor 7 is arranged on each filter element 1 , 2 , 3 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap