On-line processing method for valve assembly abnormal parts

A processing method and abnormal processing technology, which is applied in the field of valve manufacturing, can solve the problems of reducing the assembly efficiency of regulating valves, etc., and achieve the effect of improving the processing effect, improving processing efficiency, and facilitating procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is further described in detail through specific implementation methods:

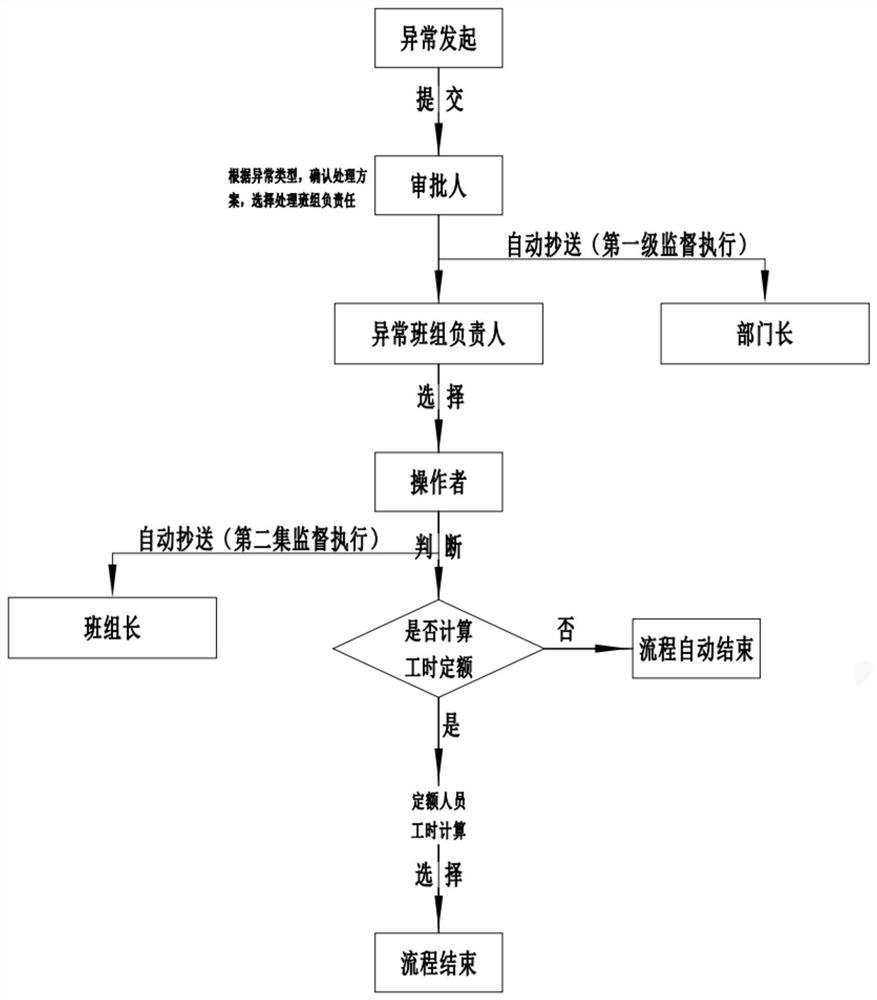

[0031] Such as figure 1 As shown, an online processing method for abnormal parts of valve assembly is mainly used in the valve assembly production line. The main purpose of this method is to realize the collaboration, division of responsibilities, and rating of man-hours among multiple departments through online processing. It is to improve the processing efficiency of the abnormal parts of the valve on the production line. The method mainly includes the following steps,

[0032] S1: Abnormal initiation, the production line staff collects the abnormal information in the assembly through the mobile intelligent terminal, and initiates an abnormal handling request to the approver through the mobile intelligent terminal; the specific operation of the production line staff on the abnormal initiation is as follows: Each assembly part is hung with a corresponding process card, and a QR cod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com