Medicine filling equipment for ointment mixed production

A technology for filling medicine and ointment, which is applied in the field of medicine filling equipment for the mixed production of ointment, which can solve the problems of inconvenient cleaning of ointment and movement of the material receiving box, and achieve the effects of reducing operability, enhancing fixity, and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

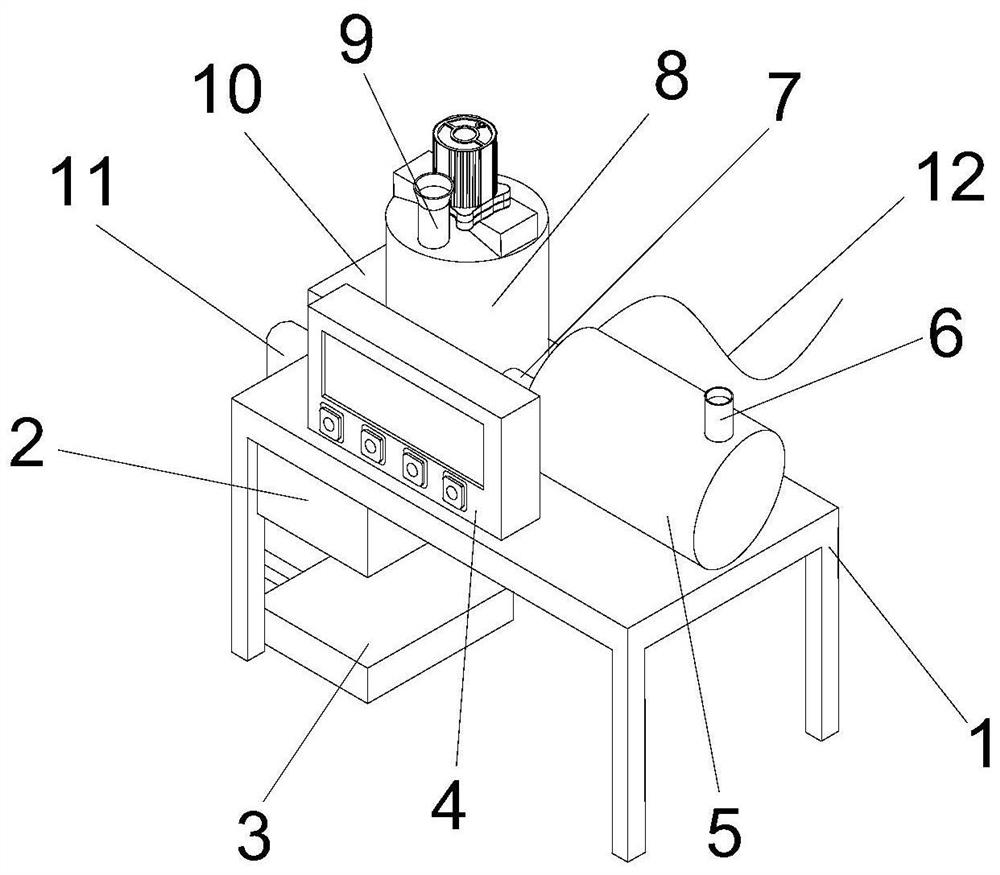

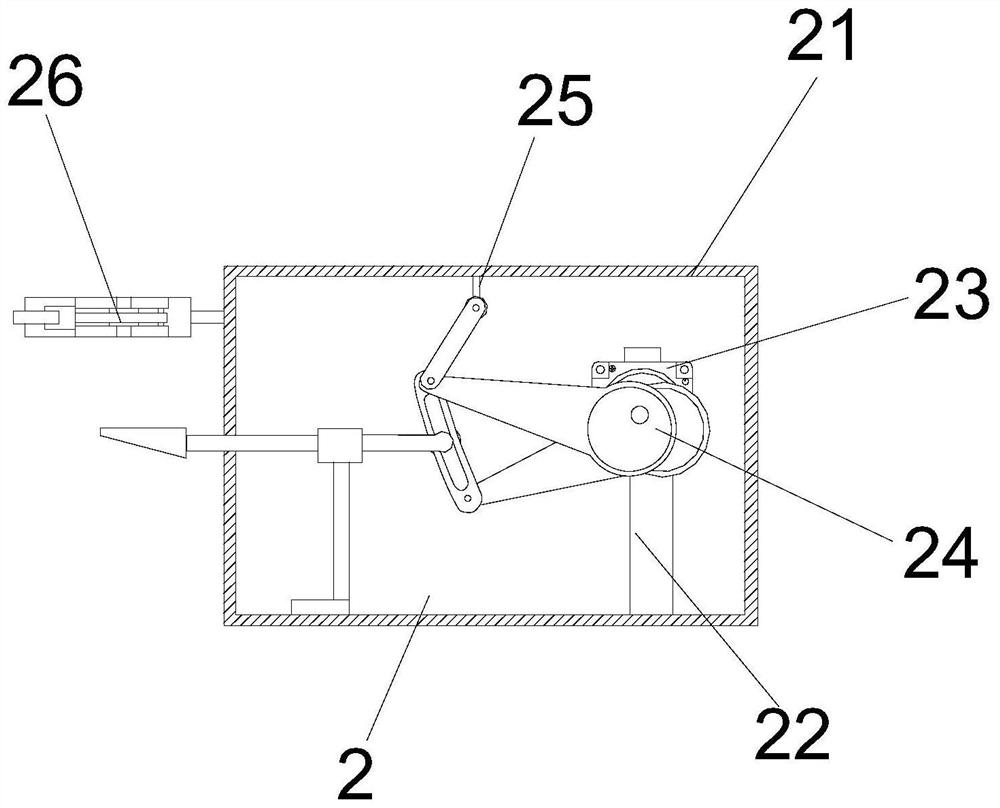

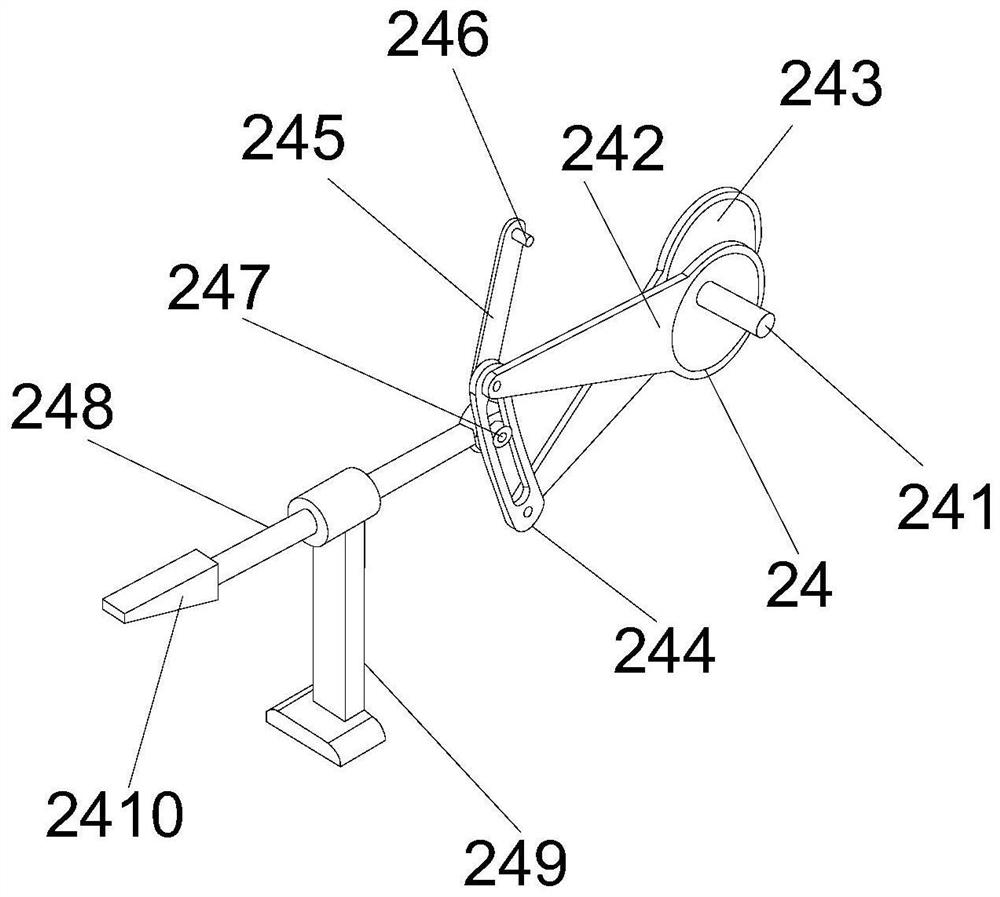

[0031] see figure 1 , the present invention provides a medicine-filling equipment for ointment mixing production through improvement, including a workbench 1, a control panel 4 is arranged at the front end of the top of the workbench 1, the middle part of the top of the workbench 1 is fixed with the water tank 5, and the right end of the top of the water tank 5 is opened There is a water inlet 6, the left side of the water tank 5 is connected to the liquid inlet 7, the left side of the liquid inlet 7 is connected to the stirring device 8, the top of the stirring device 8 is vertically provided with a feed port 9, the left side of the stirring device 8 is connected to the extrusion The device 10 is connected, the left side of the extrusion device 10 is connected with the discharge port 11, the power line 12 is arranged on the back side of the workbench 1, the top of the auxiliary mechanism 2 is fixed with the workbench 1, and the front and rear sides of the limit device 3 are co...

Embodiment 2

[0038] The present invention provides a medicine-filling equipment for the mixed production of ointment through improvement. The motor 23 described in the present invention refers to an electromagnetic device that realizes electric energy conversion or transmission according to the law of electromagnetic induction. The motor uses letters in the circuit M (the old standard is represented by D), its main function is to generate driving torque, as a power source for electrical appliances or various machinery, the generator is represented by the letter G in the circuit, and its main function is to convert mechanical energy into electrical energy .

[0039] The present invention provides a medicine-filling equipment for the mixed production of ointment through improvement, and its working principle is as follows;

[0040] First, the user can place the workbench 1 horizontally at the place where it needs to be used, and then connect the power cord 12 provided at the rear end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com