Production method of titanium alloy large-diameter square thin-walled pipe

A technology for thin-walled pipes and production methods, which is applied in the field of material processing, can solve the problems of inapplicability of cold rolling and cold drawing processes, and high requirements for hot rolling process equipment, so as to meet simple equipment requirements and operation requirements, reduce energy consumption, and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

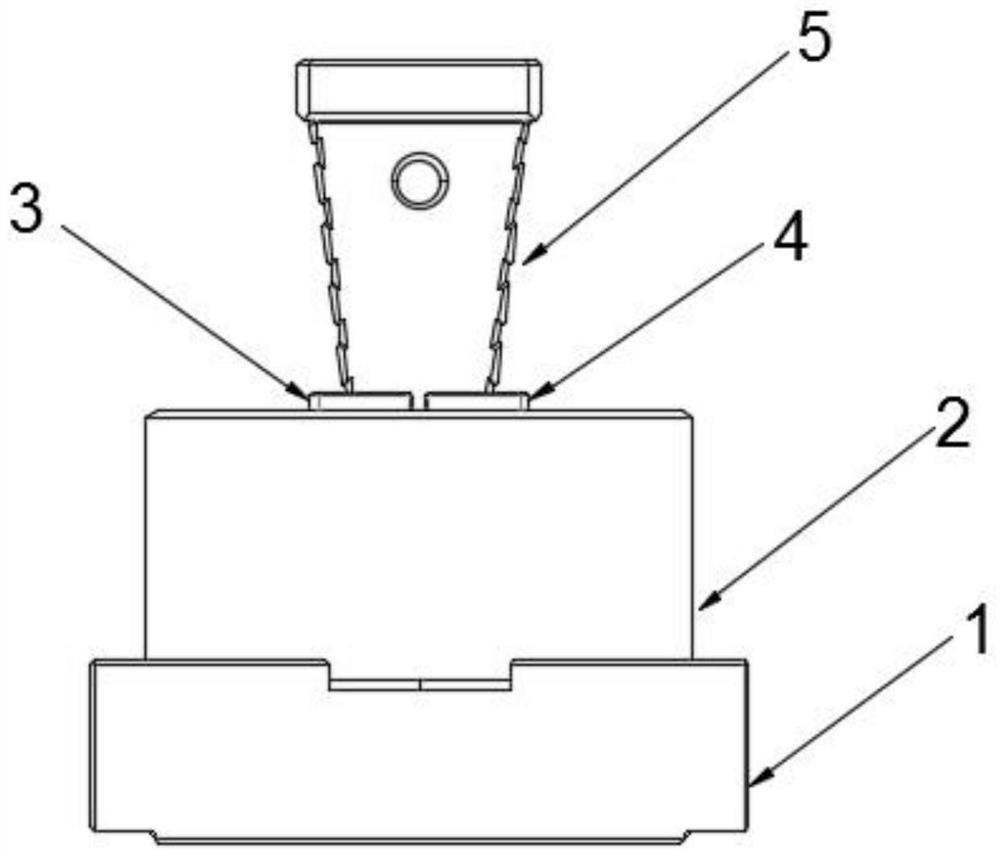

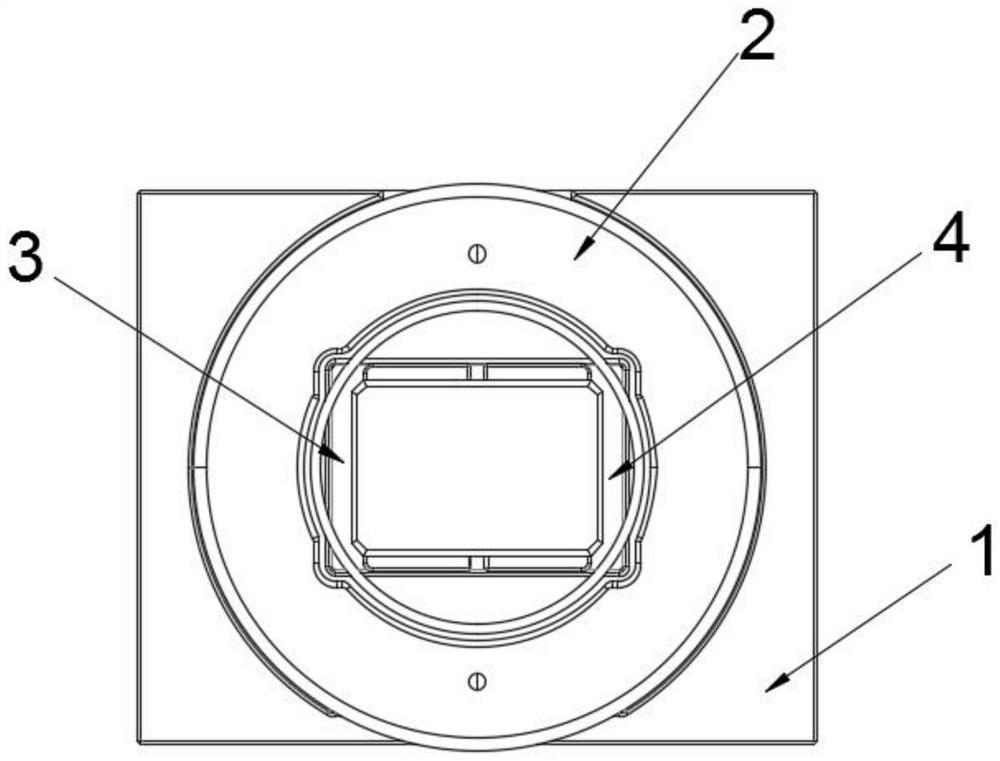

Image

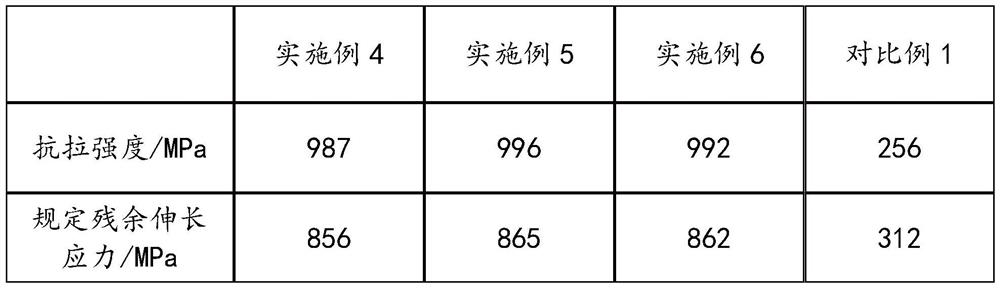

Examples

Embodiment 1

[0031] The anti-oxidation coating is prepared by the following steps:

[0032] Step S1, weighing the following raw materials in parts by weight: SiO 2 10 parts, MgO 5 parts, SiC 5 parts, ZrO 2 2 parts, 1 part of CaO, 5 parts of ceramic micropowder;

[0033] Step S2, the SiO 2 , MgO, SiC, ZrO 2 , CaO and ceramic micropowder are mixed evenly and ground finely, and filtered through a 200-mesh filter screen to obtain the base material;

[0034] Step S3, mix 31.2g of graphite powder, 23.4g of potassium persulfate, 23.1g of phosphorus pentoxide and 110.5mL of concentrated sulfuric acid with a mass fraction of 98%, and react in a water bath at 80°C for 4.5h. After cooling to room temperature, use Diluted with deionized water, washed 3 times with deionized water, and dried in an oven at 70°C for 3 hours to obtain pre-oxidized graphite powder;

[0035] Step S4, add 35.6g of pre-oxidized graphite powder into 1.2L of concentrated sulfuric acid with a mass fraction of 98%, add 150....

Embodiment 2

[0039] The anti-oxidation coating is prepared by the following steps:

[0040] Step S1, weighing the following raw materials in parts by weight: SiO 2 12 parts, MgO 5 parts, SiC 6 parts, ZrO 2 2 parts, 2 parts of CaO, 5 parts of ceramic micropowder;

[0041] Step S2, the SiO 2 , MgO, SiC, ZrO 2 , CaO and ceramic micropowder are mixed evenly and ground finely, filtered through a 250-mesh filter to obtain the base material;

[0042] In step S3, mix 32.5g of graphite powder, 24.2g of potassium persulfate, 23.5g of phosphorus pentoxide and 111.6mL of concentrated sulfuric acid with a mass fraction of 98%, and react in a water bath at 80°C for 4.5h. After cooling to room temperature, use Diluted with deionized water, washed 3 times with deionized water, dried in an oven at 75°C for 3 hours to obtain pre-oxidized graphite powder;

[0043] Step S4, add 35.8g of pre-oxidized graphite powder into 1.25L of concentrated sulfuric acid with a mass fraction of 98%, add 150.8g of 0.5m...

Embodiment 3

[0047] The anti-oxidation coating is prepared by the following steps:

[0048] Step S1, weighing the following raw materials in parts by weight: SiO 2 15 parts, MgO 6 parts, SiC 8 parts, ZrO 2 3 parts, 3 parts of CaO, 6 parts of ceramic micropowder;

[0049] Step S2, the SiO 2 , MgO, SiC, ZrO 2 , CaO and ceramic micropowder are mixed evenly and ground finely, and filtered through a 300-mesh filter screen to obtain the base material;

[0050] Step S3, mix 33.1g of graphite powder, 25.6g of potassium persulfate, 24.5g of phosphorus pentoxide and 112.4mL of concentrated sulfuric acid with a mass fraction of 98%, and react in a water bath at 80°C for 4.5h. After cooling to room temperature, use Diluted with deionized water, washed 3 times with deionized water, and dried in an oven at 80°C for 4 hours to obtain pre-oxidized graphite powder;

[0051] Step S4, add 36.8g of pre-oxidized graphite powder to 1.3L of concentrated sulfuric acid with a mass fraction of 98%, add 151.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com