Automobile precision part polishing device with clamping function

A technology for precision parts and automobiles, applied in the field of automobile parts processing, can solve the problems of low grinding efficiency, achieve high grinding efficiency, facilitate grinding processing, and avoid dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

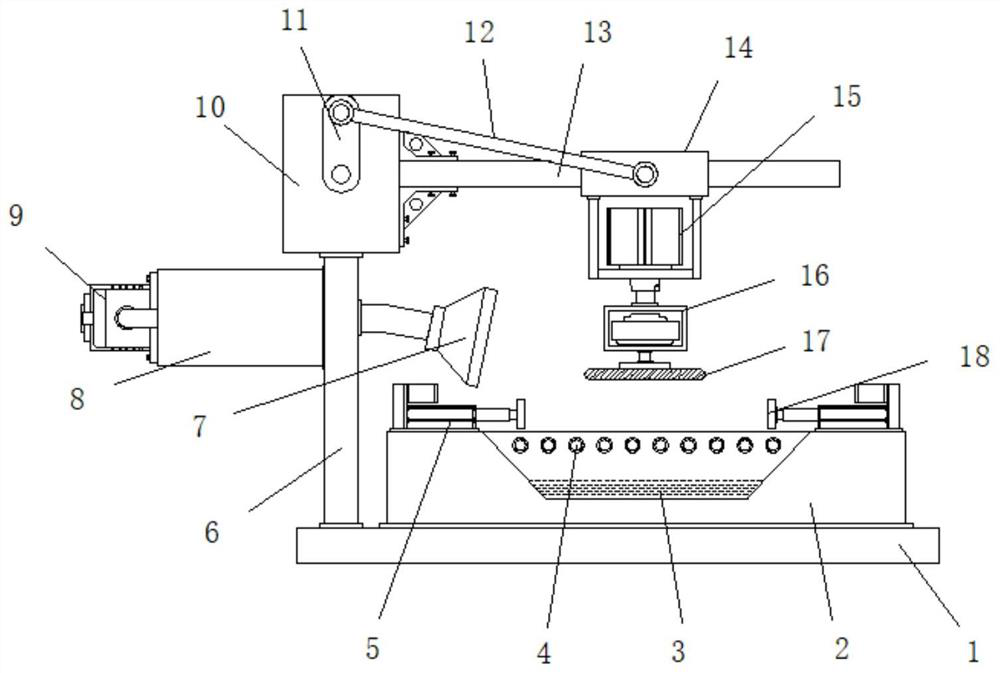

[0020] Example 1: See Figure 1-4 , a grinding device for automotive precision parts with a clamping function, comprising a bottom plate 1 and a vertical plate 6, the vertical plate 6 is vertically fixed on one side of the top of the bottom plate 1, and a dust box 8 is fixed on one side of the vertical plate 6, A filter element 20 is installed inside the dust collection box 8, a dust collection cover 7 and an exhaust fan 9 are installed outside the dust collection box 8, a base 2 is fixedly arranged on the top of the bottom plate 1, and electric push rods are respectively fixed on both sides of the top of the base 2 5. There is a water tank 3 inside the base 2, a support plate 10 is fixed on the top of the riser 6, and a reciprocating grinding mechanism is arranged on the support plate 10;

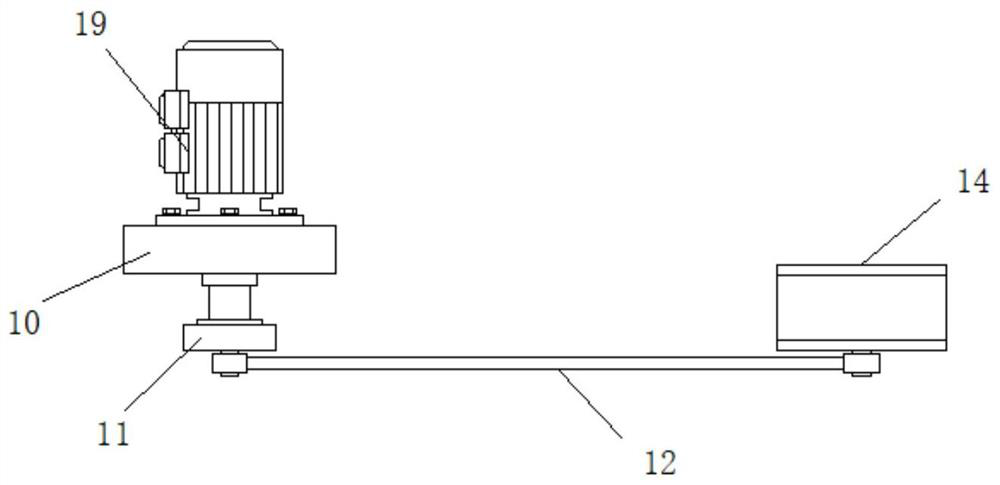

[0021] see Figure 1-4 , a grinding device for automotive precision parts with a clamping function also includes a reciprocating grinding mechanism, the reciprocating grinding mechanism i...

Embodiment 2

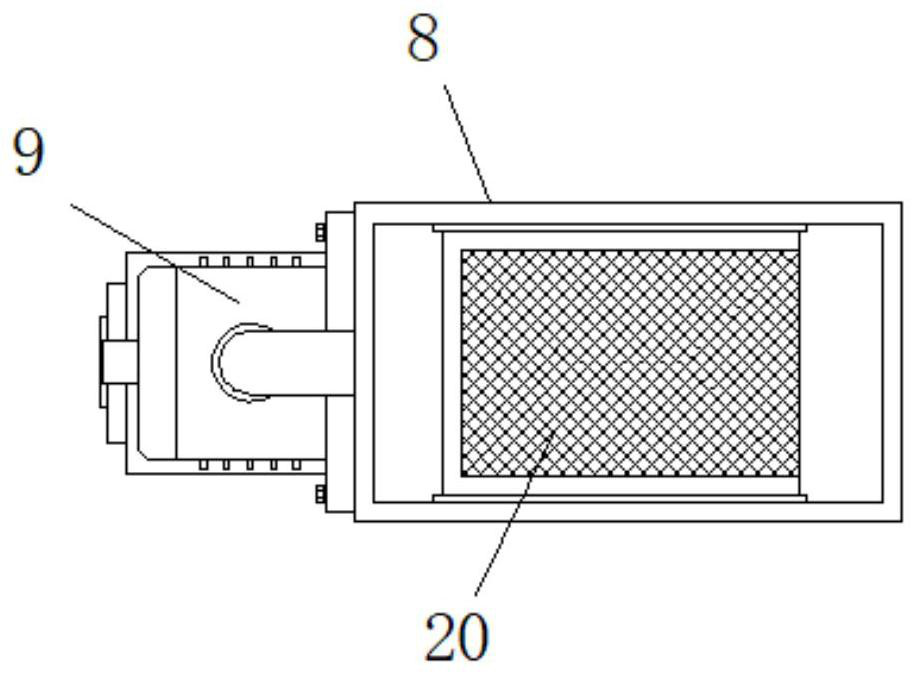

[0023] Embodiment 2: the outer wall of the filter element 20 is fixed on the inner wall of the dust collection box 8, one side of the dust collection cover 7 runs through the inside of the vertical plate 6, and one side of the dust collection cover 7 is fixed on one side of the dust collection box 8 side, the exhaust fan 9 is fixedly installed on the other side of the dust collection box 8, the dust collection cover 7 communicates with one side of the dust collection box 8 through the flange, and the input end of the exhaust fan 9 is connected to the other side of the dust collection box 8. side connection;

[0024] Specifically, such as figure 1 and image 3 As shown, in the process of grinding, start the exhaust fan 9, and the exhaust fan 9 will suck the air containing dust into the inside of the dust collection box 8 through the dust collection cover 7, and the filter element 20 inside the dust collection box 8 will filter the dust. Collect, so that the fine dust particle...

Embodiment 3

[0025] Embodiment 3: The electric push rod 5 is symmetrically arranged on both sides of the top of the base 2, and the output end of the electric push rod 5 is fixed with a splint 18, and the top of the water tank 3 is equidistantly inserted with the support rod 4;

[0026] Specifically, such as figure 1 and Figure 4 As shown, the auto parts are first placed on the support rod 4, and then the electric push rod 5 is started, and the electric push rod 5 drives the splint 18 to clamp and fix the auto parts, and then the debris generated by grinding will fall in the inside of the water tank 3, Being wetted by the water inside the tank 3, the debris is collected, greatly improving the functionality of the device.

[0027] Working principle: when the present invention is in use, first, place the auto parts on the support rod 4, then start the electric push rod 5, and the electric push rod 5 drives the splint 18 to clamp and fix the auto parts. At this time, start the drive motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com