Full-automatic clamping equipment for rare earth metal detection

A rare earth metal, fully automatic technology, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of heavy inspection tasks and high labor intensity of inspection personnel, so as to improve the service life of equipment, improve maintenance efficiency, and eliminate equipment vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

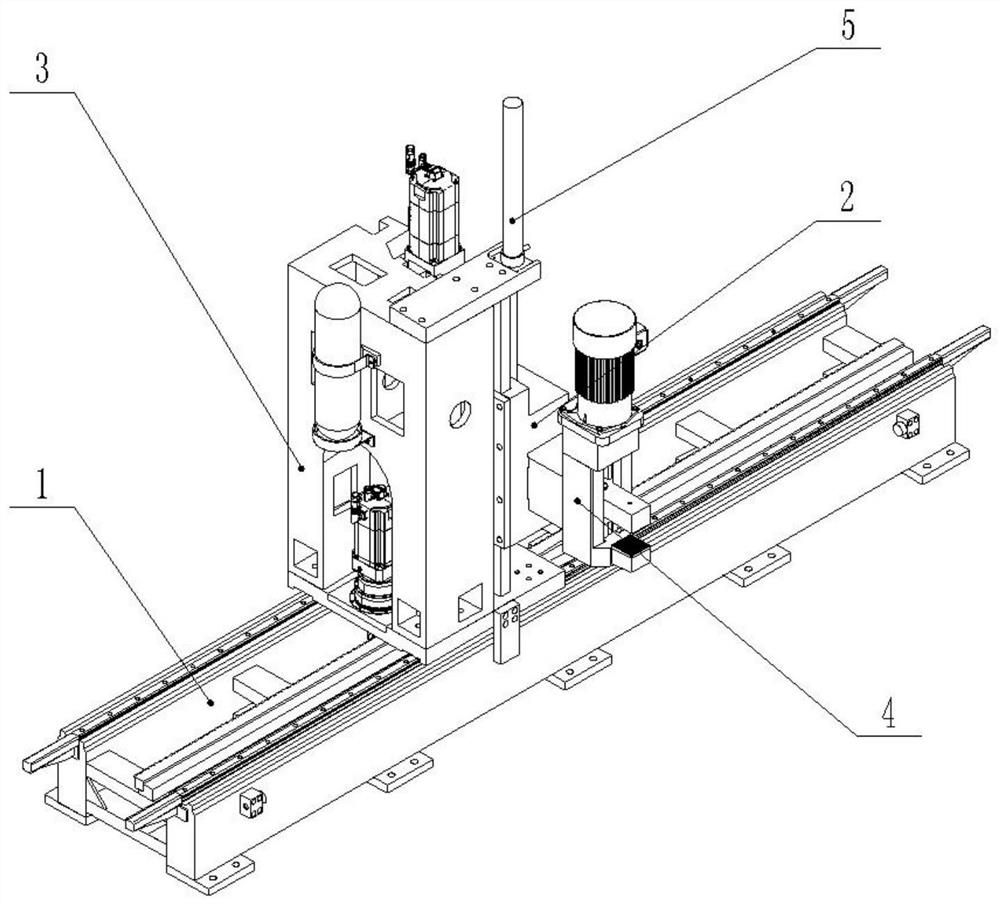

[0026] Such as figure 1 As shown, a fully automatic clamping device for rare earth metal detection includes an X-axis moving module 1, a Y-axis telescopic module 2, a Z-axis lifting module 3, and a jaw module 4. The jaw module 4 is installed on the Y-axis telescopic On the module 2, the Y-axis telescopic module 2 is installed on the Z-axis lifting module 3, and the Z-axis lifting module 3 is installed on the X-axis moving module 1.

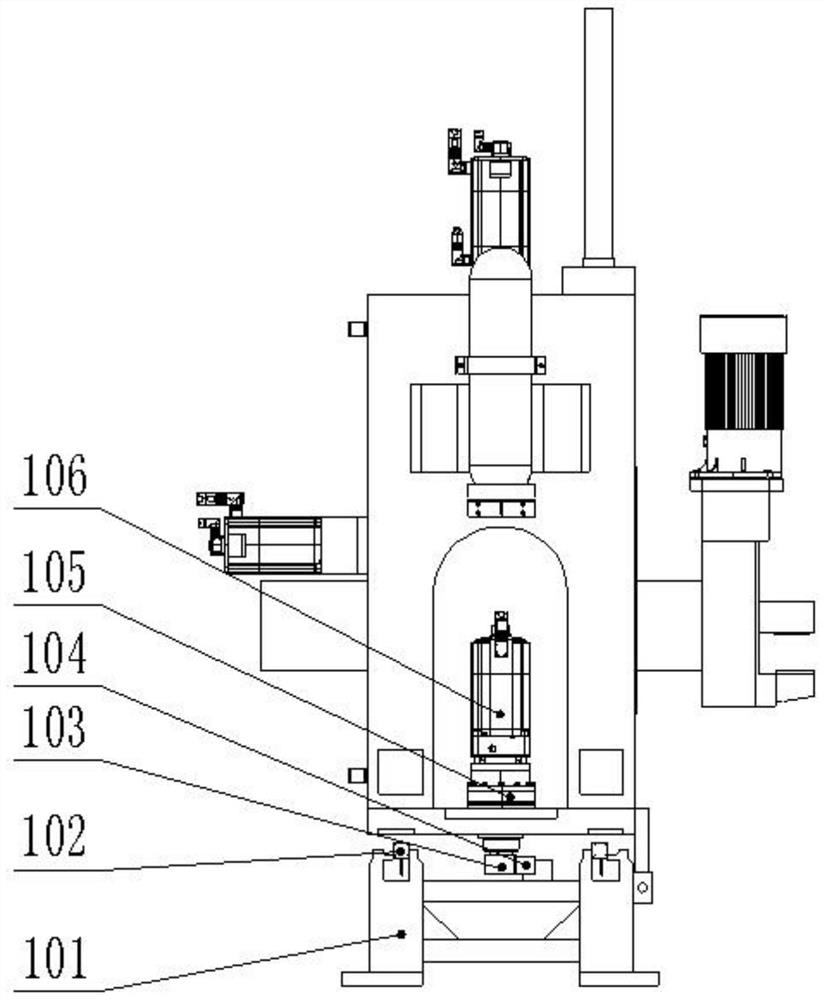

[0027] Such as figure 2 As shown, the X-axis moving module 1 includes a manipulator base 101, a linear guide rail module 102, a gear 103, a rack 104, a reducer 105 and a first drive motor 106, and two linear guide rail modules 102 are arranged in parallel on the top of the manipulator base 101, The linear guide rail module 102 is slidingly connected to the Z-axis lifting module 3, and the Z-axis lifting module 3 is provided with a reducer 105. The power input shaft of the reducer 105 is equipped with a first drive motor 106, and the upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com