Crossed secondary core pulling mold

A secondary core-pulling and cross-type technology, applied in the field of molds, can solve problems such as high manufacturing cost, complex structure, and poor stability, and achieve the effects of reducing maintenance difficulty, simplifying the core-pulling structure, and reducing failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

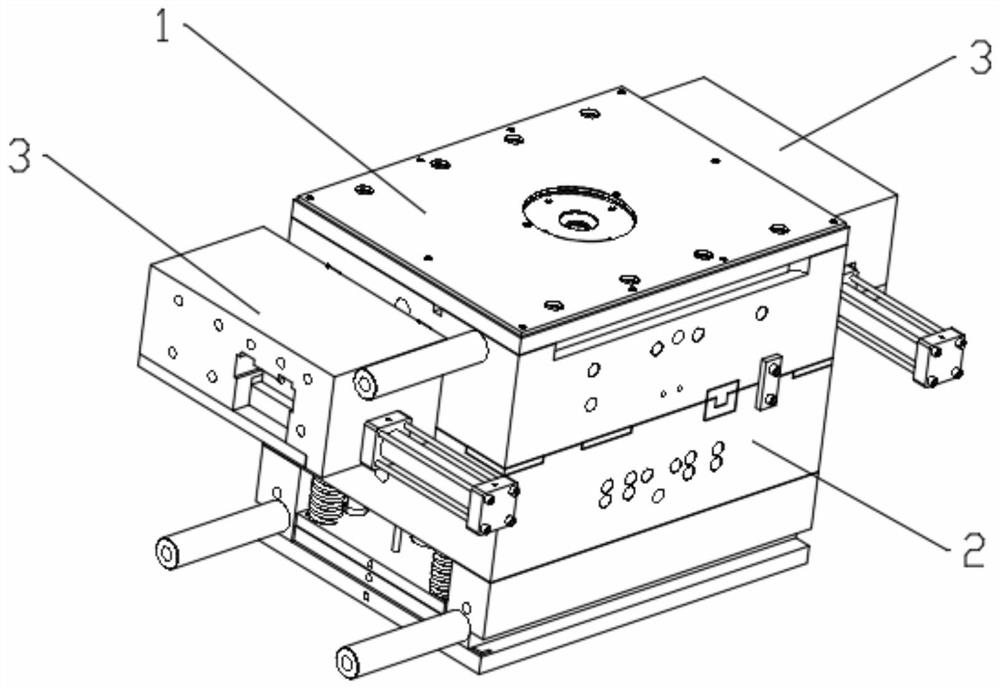

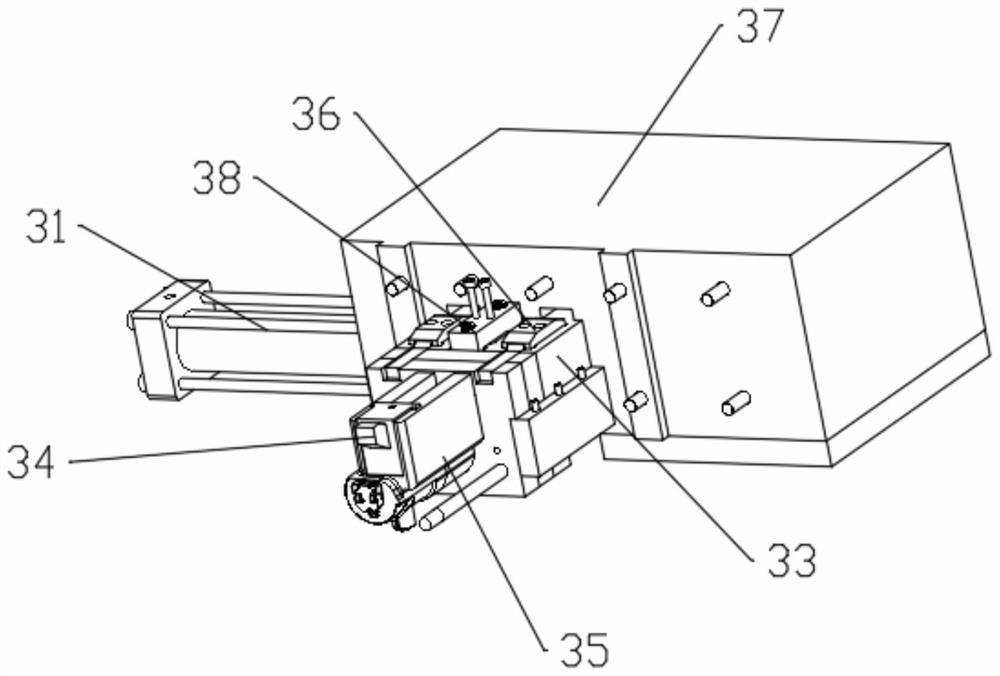

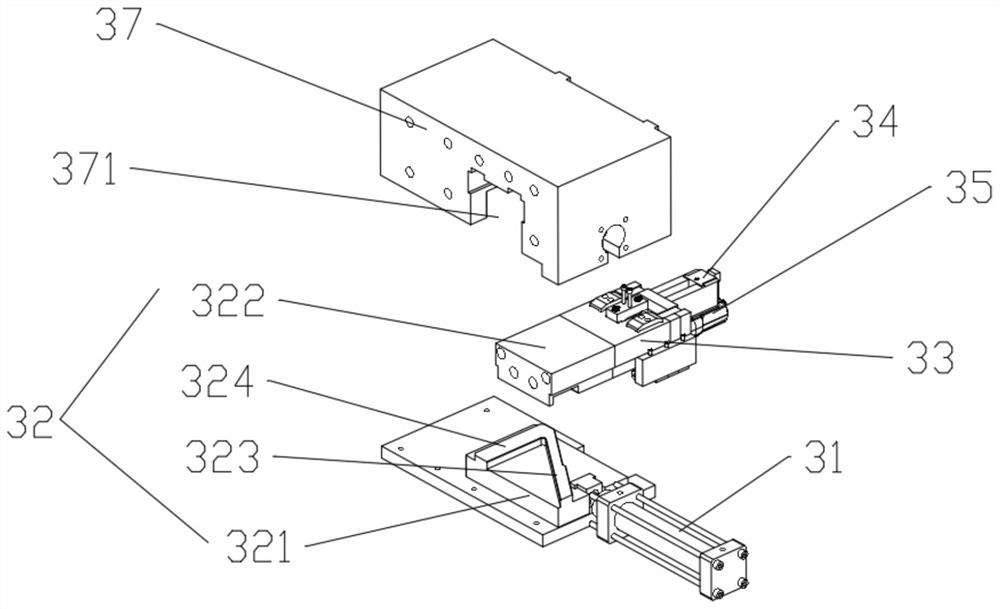

[0041] see Figure 1-9 , this embodiment discloses a cross-type secondary core-pulling mold, including a movable mold 1, a fixed mold 2 and a core-pulling assembly 3, the movable mold 1 is located above the fixed mold 2, and the movable mold 1 and the fixed mold 2 are arranged opposite The molding cavity 4 is formed, and the lifting rod can be set between the fixed mold 2 and the movable mold 1, and the lifting cylinder, the lifting cylinder and the lifting rod can also be fixed on the movable mold 1 or the fixed mold 2, so as to complete the moving mold 1 and the fixed mold 2 between mold opening and mold closing actions.

[0042] In this embodiment, there are two core-pulling assemblies 3 , and the two core-pulling assemblies 3 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com