Carding machine card clothing suitable for producing non-woven fabrics and preparation method of carding machine card clothing

A technology of non-woven fabrics and card clothing, applied in the field of carding machines, which can solve the problems of cumbersome gauge pass rate inspection, unsatisfactory messy effect, and large damage to long fibers, etc., to achieve good messy effect and scientific and reasonable card clothing structure design , reducing the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

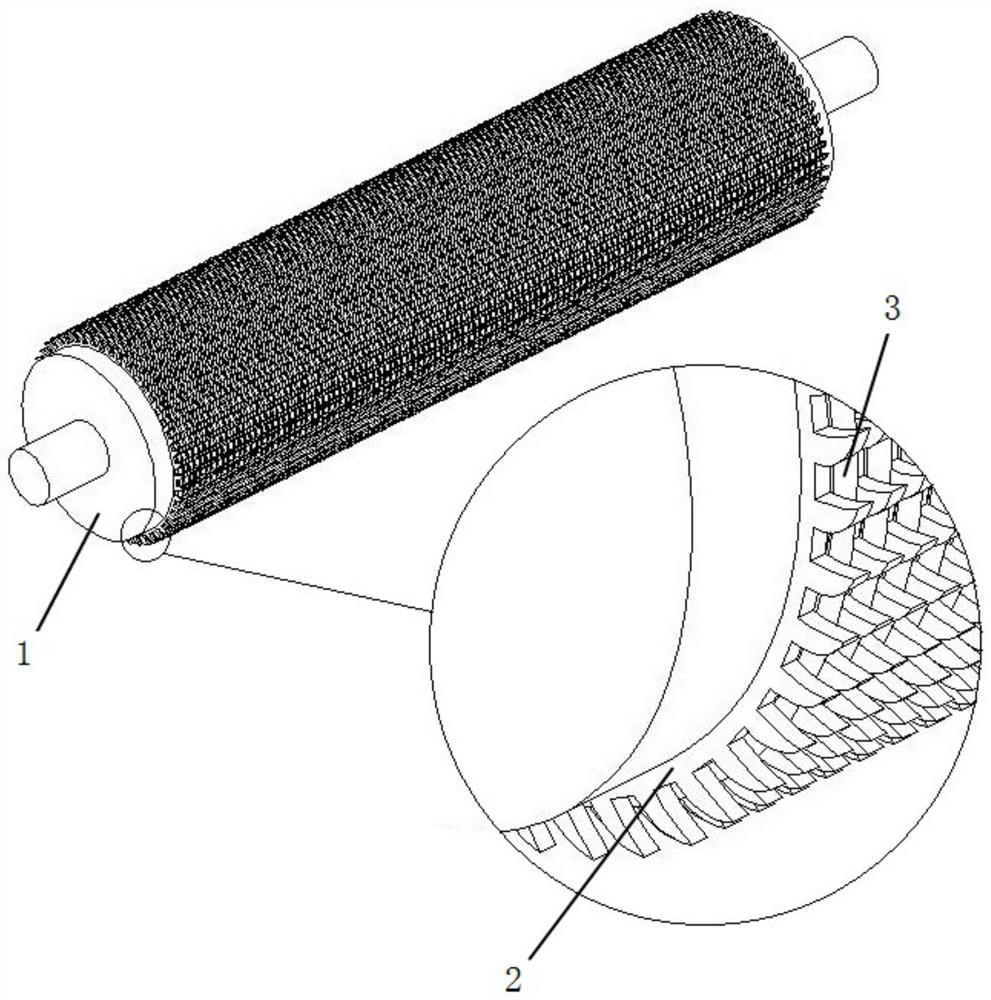

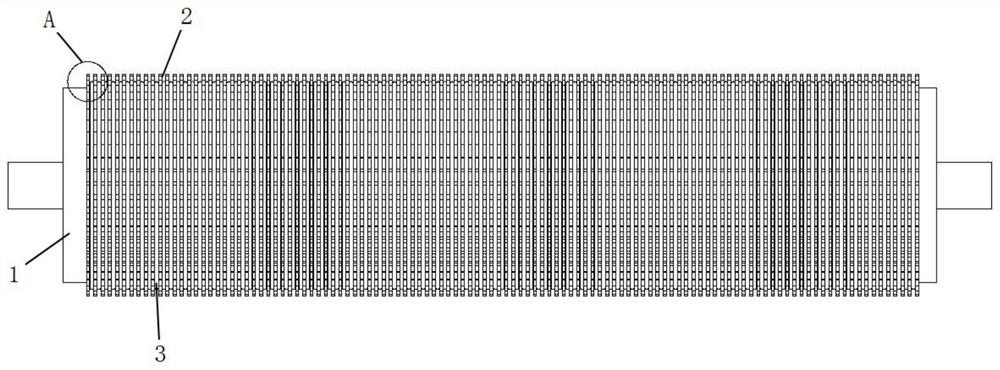

[0033] The invention provides a card clothing suitable for producing non-woven fabrics and a preparation method thereof.

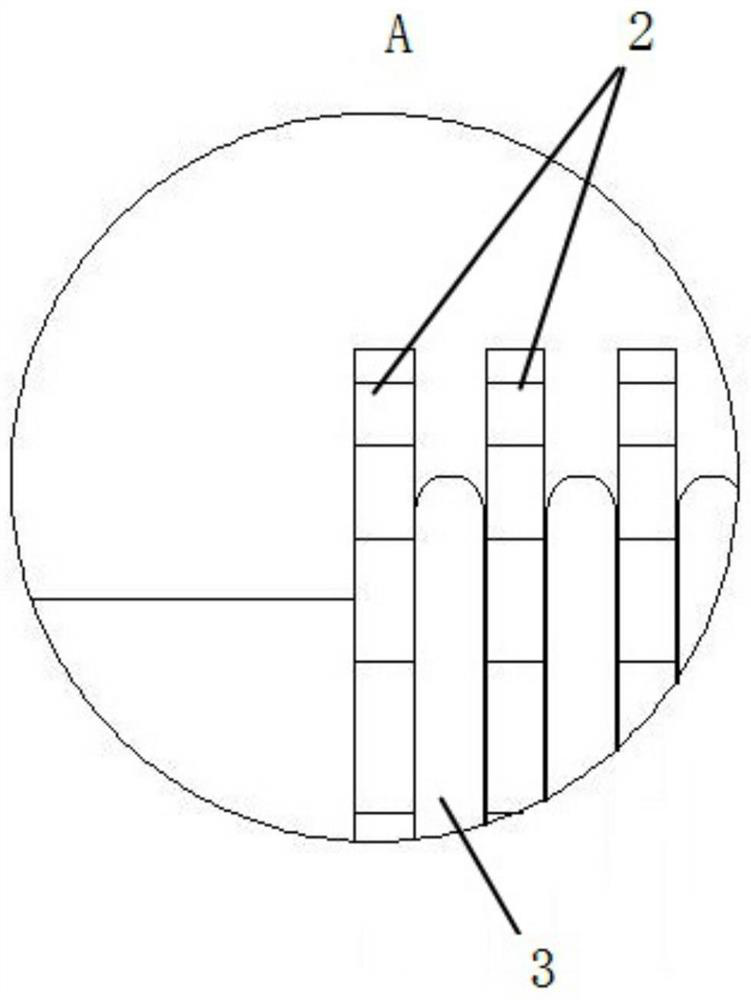

[0034] The card clothing comprises a carrier 1 , a card clothing winding layer 2 and at least one insulation wire winding layer 3 . The carrier 1 is a columnar structure with a columnar winding surface on its outer periphery. The card clothing winding layer 2 has a helical structure, which is formed by helically winding the card clothing along the cylindrical winding surface, and an isolation area is left between two adjacent turns of the card clothing. The insulating wire winding layer 3 has a spiral structure, which is formed by spirally winding the insulating wire along the cylindrical winding surface, and the insulating wire is located in the isolation area.

[0035] The preparation method of above-mentioned carding machine card clothing comprises the steps:

[0036] S1. Install the carrier 1 on the rotating bracket, and install the card clothing rol...

Embodiment 1

[0041] Such as figure 1 , figure 2 and image 3 As shown, this embodiment is a card clothing suitable for producing non-woven fabrics, including a carrier 1 , a card clothing winding layer 2 and a layer of insulating wire winding layer 3 . The carrier 1 is a columnar structure with a columnar winding surface on its outer periphery. The card clothing winding layer 2 has a helical structure, which is formed by helically winding the card clothing along the cylindrical winding surface, and an isolation area is left between two adjacent turns of the card clothing. The insulating wire winding layer 3 has a spiral structure, which is formed by spirally winding the insulating wire along the cylindrical winding surface, and the insulating wire is located in the isolation area.

[0042] Wherein, the card clothing in the card clothing winding layer 2 is a metal card clothing.

[0043] Wherein, the section of the isolation wire is circular, and the material of the isolation wire is w...

Embodiment 2

[0045] This embodiment is a card clothing suitable for producing non-woven fabrics, including a carrier 1 , a card clothing winding layer and a layer of insulating wire winding layer 3 . The carrier 1 is a columnar structure with a columnar winding surface on its outer periphery. The card clothing winding layer 2 has a helical structure, which is formed by helically winding the card clothing along the cylindrical winding surface, and an isolation area is left between two adjacent turns of the card clothing. The insulating wire winding layer 3 has a spiral structure, which is formed by spirally winding the insulating wire along the cylindrical winding surface, and the insulating wire is located in the isolation area.

[0046] Wherein, the card clothing in the card clothing winding layer 2 is a metal card clothing.

[0047] Wherein, the section of the isolation wire is circular, and the material of the isolation wire is welding wire with an outer diameter of 1.2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com