Pin assembly and assembling process thereof

An assembly process and assembly technology, applied in the field of fastening parts, can solve the problems of shortening the service life, unable to load materials, affecting the efficiency of enterprises, etc., to achieve the effect of improving efficiency, avoiding breakage failure, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

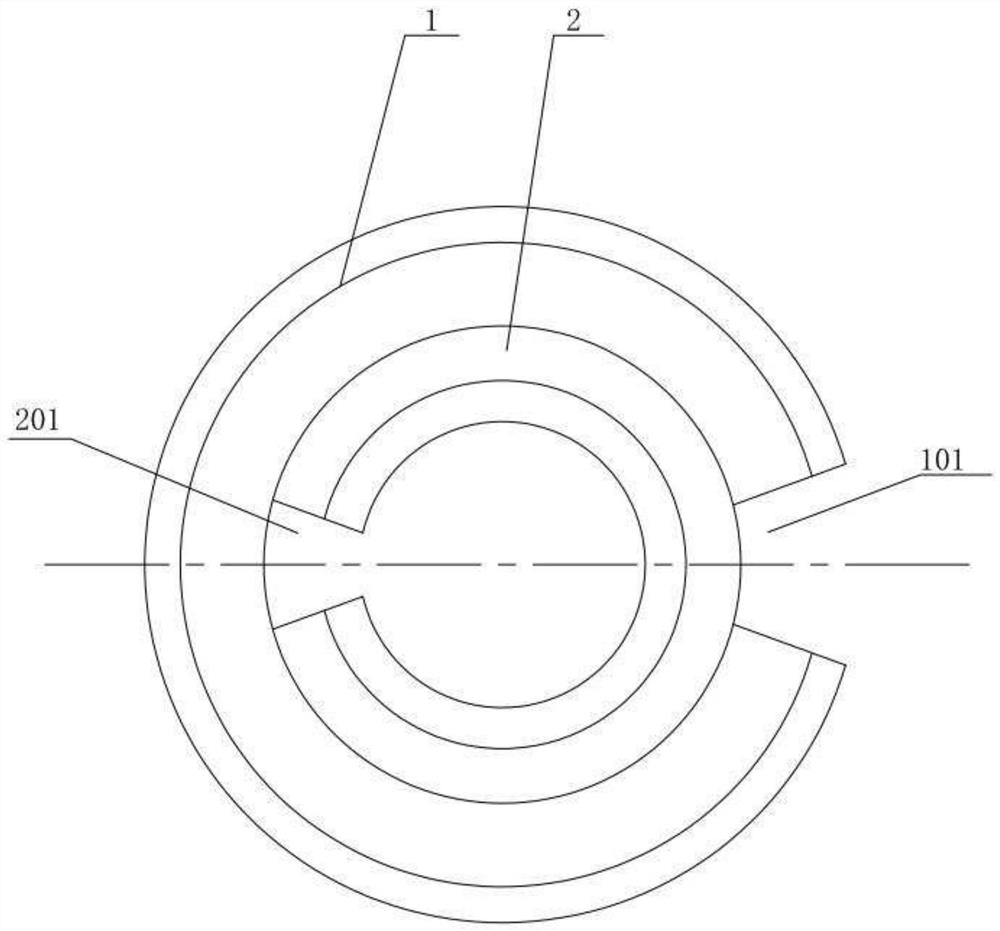

[0037] Please refer to figure 1 and figure 2 , the pin assembly includes an outer pin 1 and an inner pin 2 connected to the outer pin 1 .

[0038] Below first describe the concrete structure of export part 1 as follows:

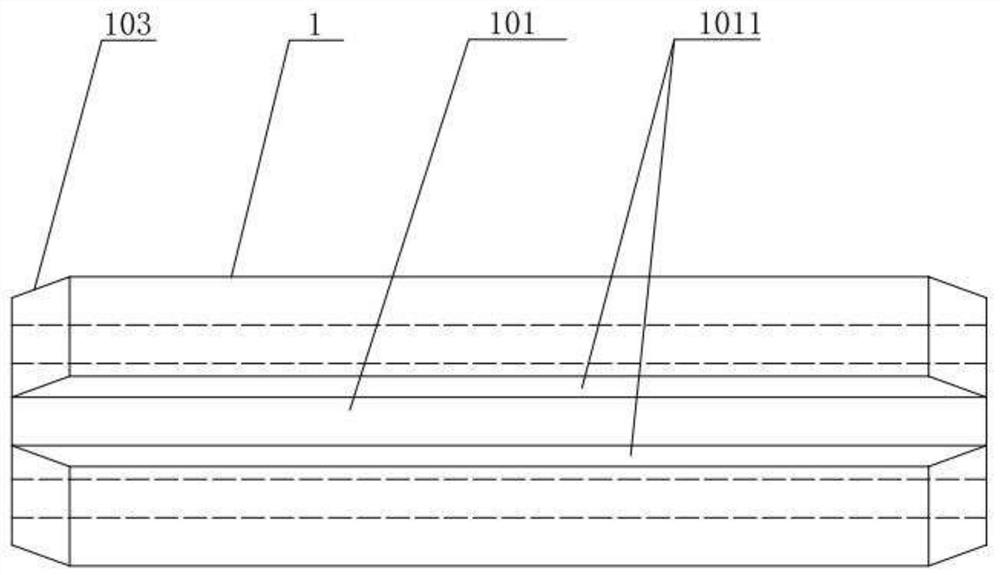

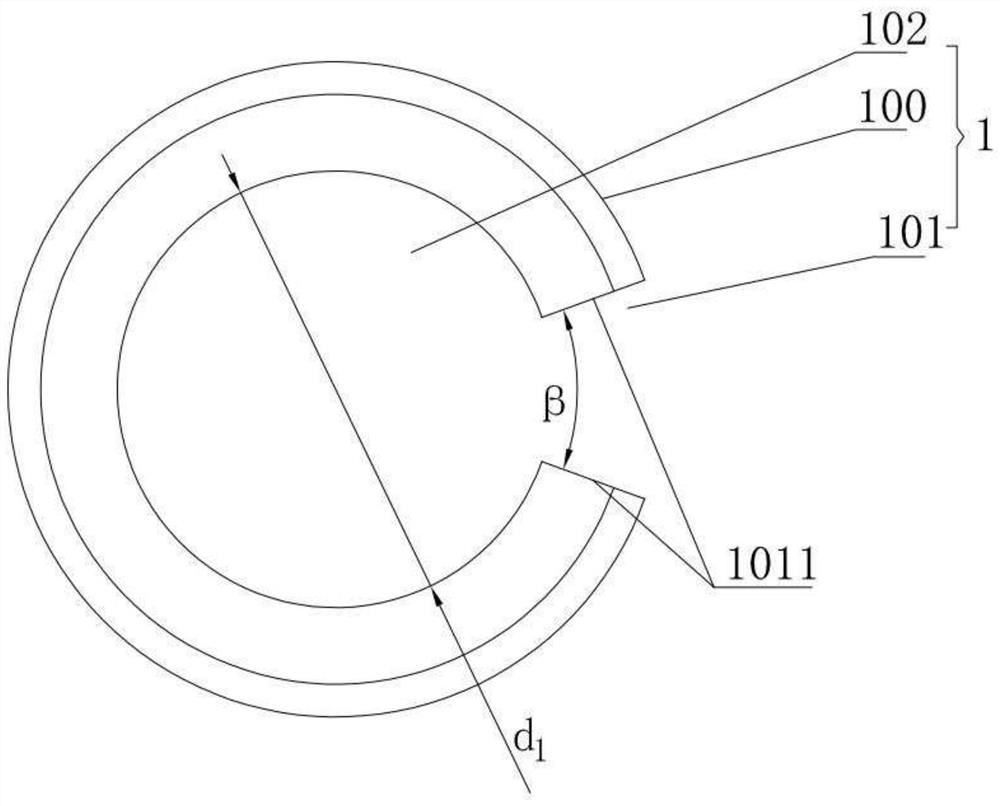

[0039] Please refer to figure 1 and image 3 , the outer pin member 1 includes a first pin body 100 having a first hole 102, preferably, the first pin body 100 is cylindrical, wherein the first hole 102 is along the axis of the first pin body 100 To open, a first slot 101 is opened on the first pin body 100 .

[0040] Further, please continue to refer to figure 1 and image 3 , the first groove 101 communicates with the first hole 102, the first groove 101 is opened along the axial direction of the first pin body 100, please refer to figure 2 , and the groove length of the first groove 101 is equal to the length of the first pin body 100 .

[0041] Further, please continue to refer to figure 1 , figure 2 and image 3 , the first groove 101 has t...

Embodiment 2

[0064] Please refer to Figure 6 The structure and manufacturing process of the second embodiment are mostly the same as those of the first embodiment. The second slot 201 partially overlaps with the first slot 101 . Specifically, the second groove 201 has a groove width of 1 / 3-2 / 3 that coincides with the first groove 101 of the outer pin 1, wherein the groove width of the second groove 201 specifically refers to the groove width close to the inner pin 2. At the outer diameter of , the distance L between two adjacent second groove walls 2011 1 . In the above case, the first groove 101 and part of the second groove 201 have overlapping parts, so that the first groove 101 is partially closed, so when it contacts with other cylindrical pins with grooves, it cannot be nested, thereby avoiding the automatic assembly process The problem of low assembly efficiency caused by product nesting.

Embodiment 3

[0066] Please refer to Figure 7 The structure and manufacturing process of the third embodiment are mostly the same as those of the first embodiment, except that the structure is different, specifically, the extension lines of the two adjacent first groove walls 101 in the outer pin 1 do not have intersecting parts, so that The first groove 101 is formed as a straight groove, and the second groove 201 of the inner pin 2 is also a straight groove, and the groove width L of the first groove 101 is 2 Greater than the groove width L of the second groove 201 3 By making the groove width of the second groove 201 smaller than the groove width of the first groove 101, even when the second groove 201 of the inner pin 2 is rotated to the first groove 101, other cylindrical pins can be prevented from nesting with the outer pin 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com