Method for reducing failure rate of knife switch on 10KV column

A technology of failure rate and knife switch, applied in the direction of prior contact arrangement, air switch components, etc., can solve problems such as prominent safety hazards, large force on the porcelain body of the knife gate pillar, and fracture failure of the porcelain body, so as to reduce power outages and transmission The effect of increasing the number of operations, improving the force status of the knife switch, and improving the reliability of power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

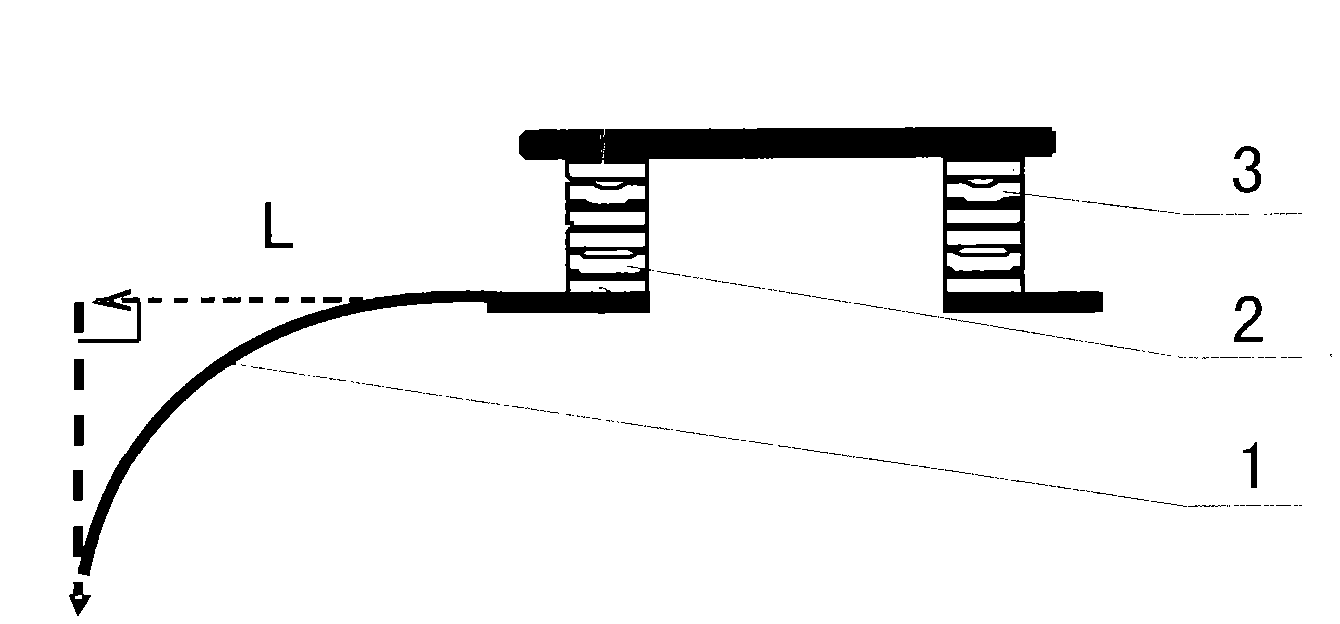

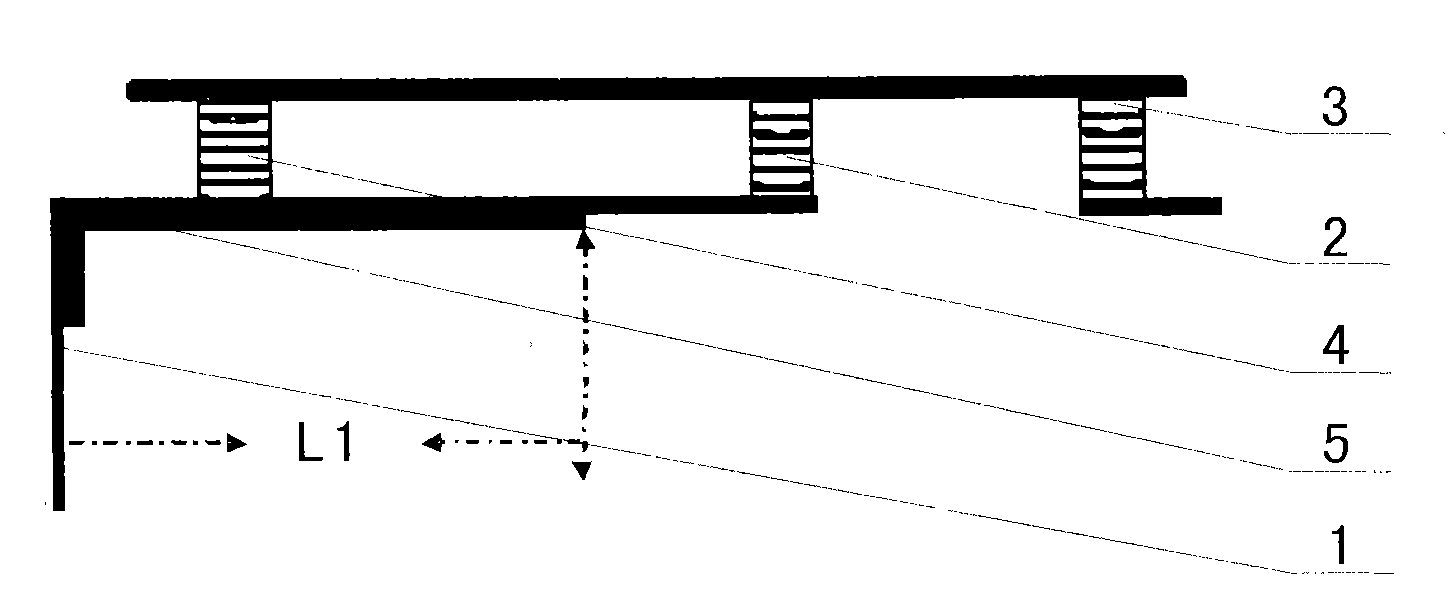

[0014] Such as figure 2 As shown in , the knife switch for reducing the failure rate of the knife switch on the 10KV column according to the present invention, the lower part of the moving contact 2 is fastened with bolts to connect the copper bar 5, and the connecting plate on the upper part of the moving contact 2 and the static contact 3 One end extends horizontally, and there is a hole on the extension plate of the connecting plate, and a hole is also provided at the corresponding position of the connecting copper bar, and an insulating support 4 is installed between the above two holes; the end of the connecting copper bar 5 is 90° downward Extend a plate for connecting cables.

[0015] One end of the connection plate on the upper part of the above-mentioned dynamic and static contacts can also be connected with a connection plate by bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com