Method for determining reserved heat gap between carbon scraping ring and cylinder cover and engine

A technology of engine and carbon ring, applied in computer-aided design, instrumentation, electrical digital data processing, etc., can solve problems such as cylinder head strength weakening, affecting thickness, fatigue fracture of cylinder liner support shoulder position, etc., to avoid fracture failure, accurate Definite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

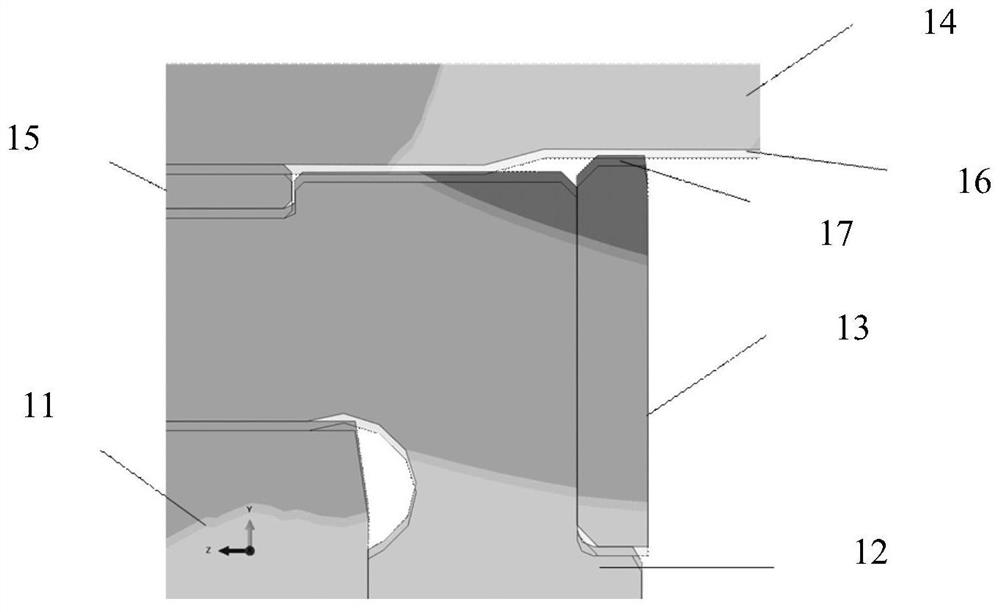

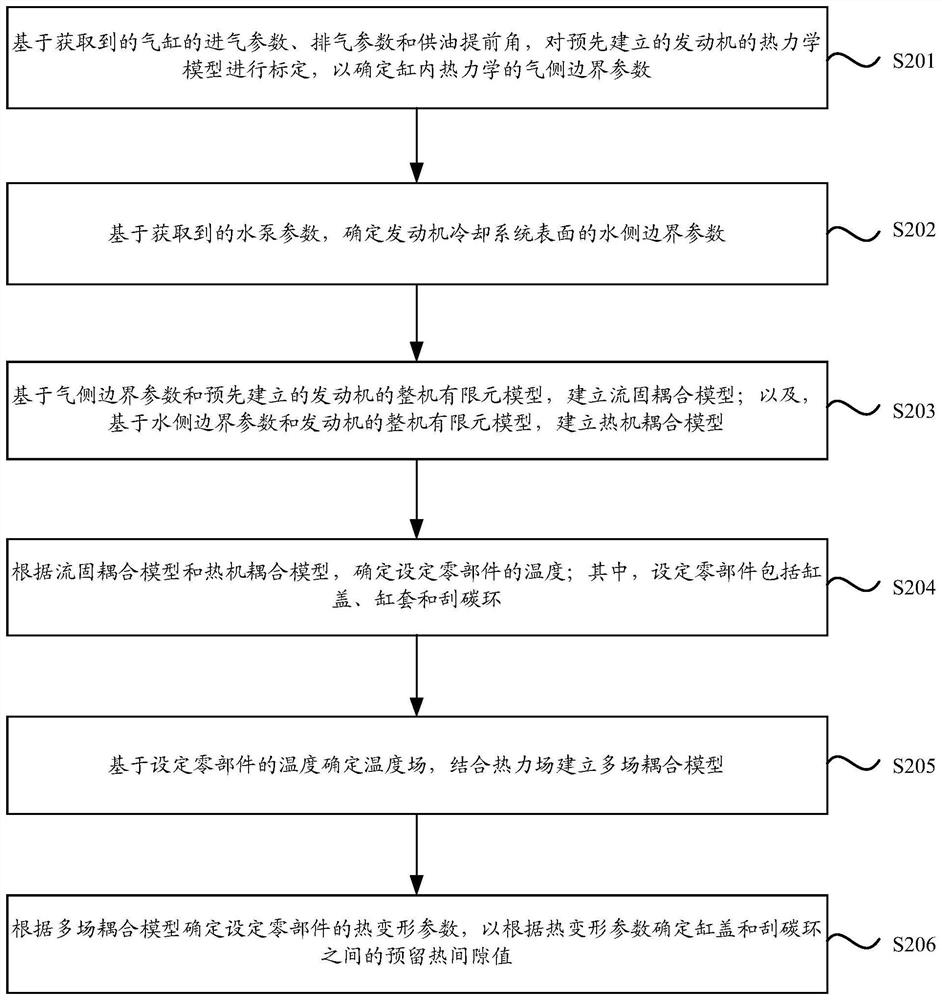

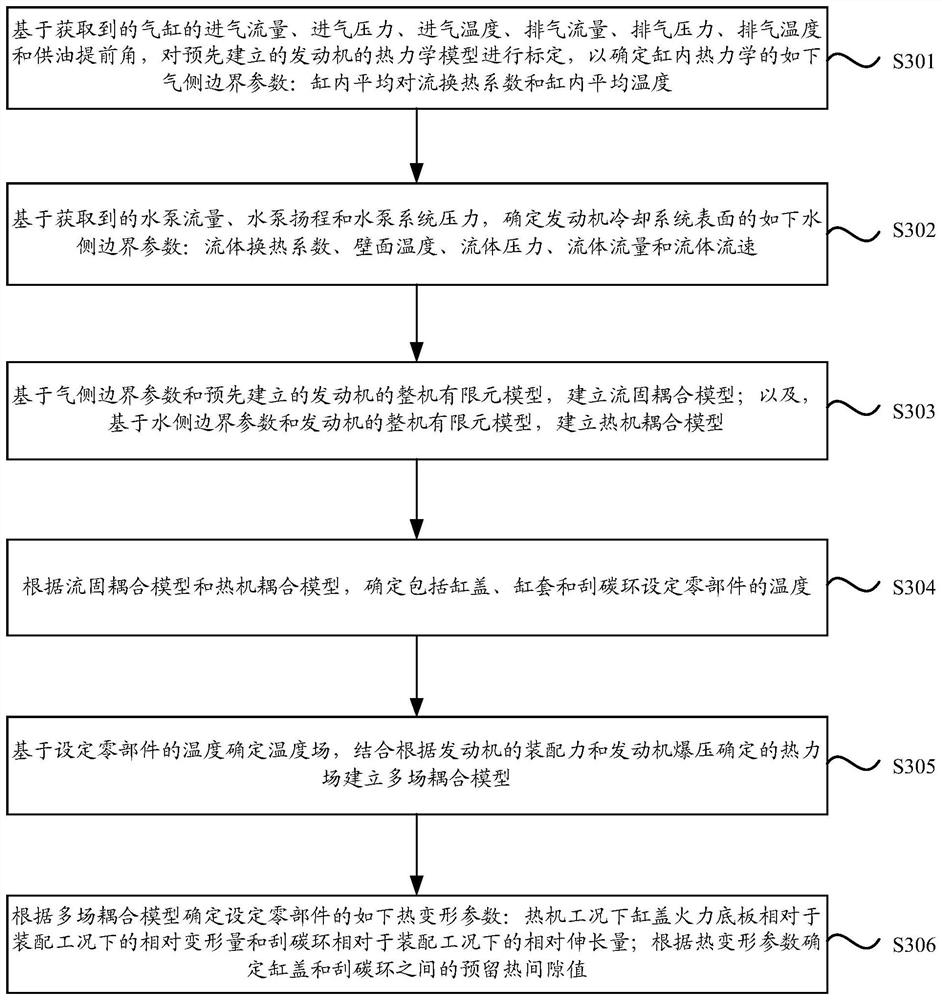

[0045] In order to make the purpose, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

[0046] For the convenience of understanding, the nouns involved in the embodiments of the present application are explained below:

[0047] (1) Cylinder head: An important part of the engine, the function is to seal the cylinder and form a combustion space together with the piston. During work, it is in direct contact with high-temperature gas and bears a high heat load.

[0048] (2) Cylinder block: It connects the cylinder and the crankcase as a whole, and is the skeleton for installing engine parts.

[0049](3) Cylinder liner: Inlaid in the cylinder barrel of the cylinder block, it forms a combustion chamber with the piston and the cylinder head. During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com