Unattended entry and exit management device for automobile coal

A management device, entry and exit technology, applied in measuring devices, special scales, weighing equipment for continuous material flow, etc., can solve the problems of complex operation, many charging steps, low operation efficiency, etc. The effect of preventing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

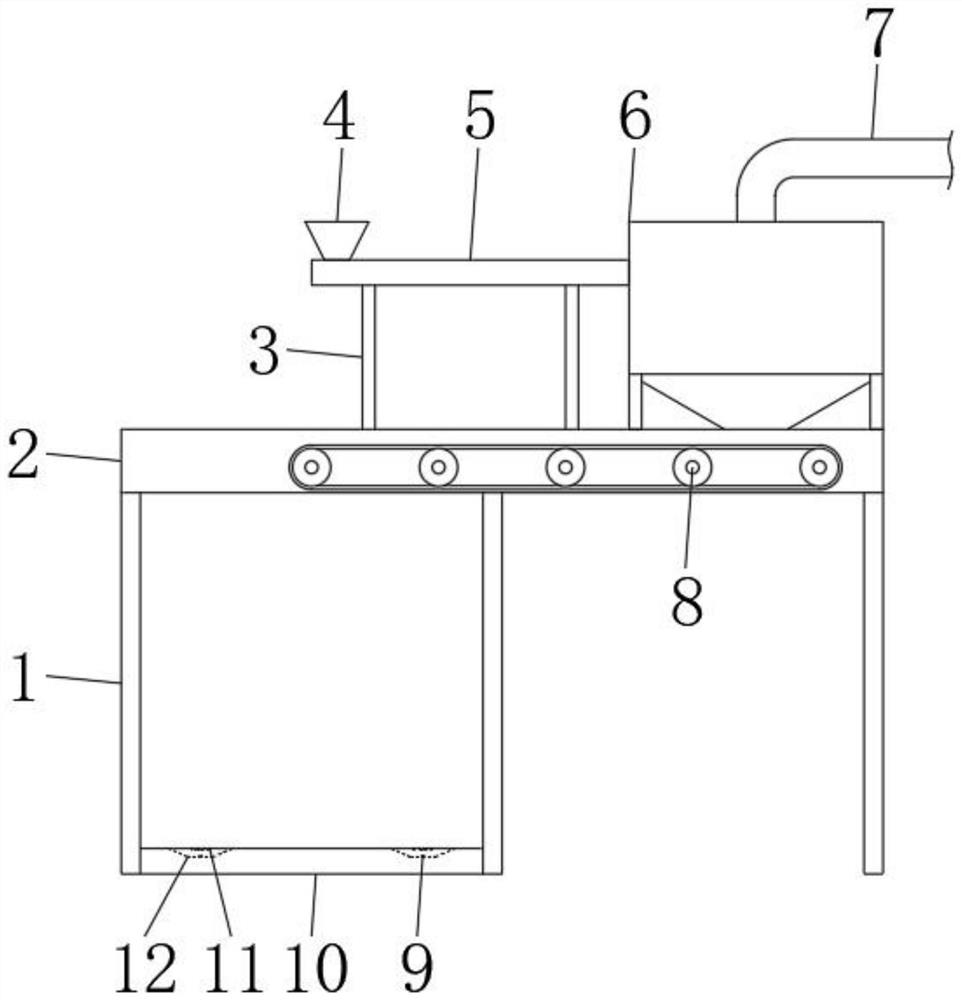

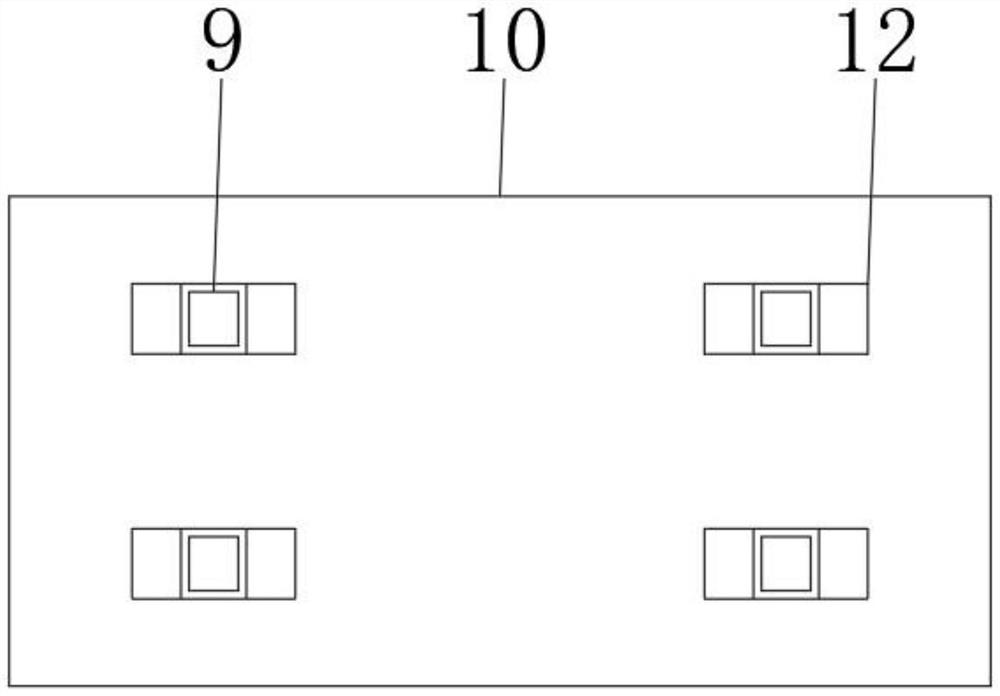

[0033] S1. When the vehicle is in place, the weighbridge 10 detects the weight of the vehicle, and the user gets off the vehicle to operate the touch screen. At the same time, the weighbridge 10 detects the vehicle weight data and lasts for more than 10 seconds;

[0034] S2. The telescopic rod of the hydraulic cylinder 9 of the weighbridge 10 is retracted, so that the wheel enters the positioning groove 12 to position the vehicle, and the indication of the weighbridge 10 is reset to zero;

[0035] S3. The user inputs the required loading weight through the touch screen and pays the fee;

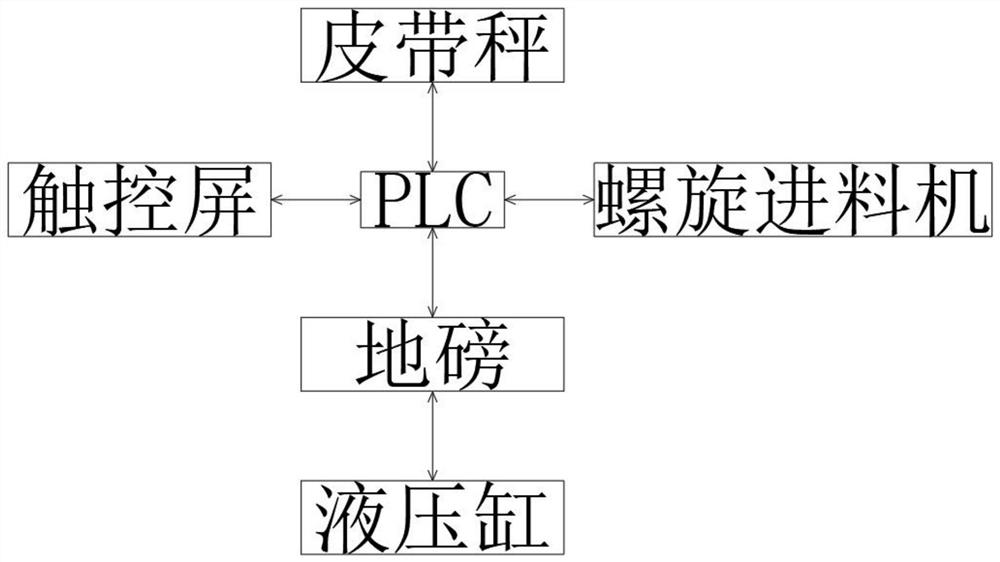

[0036] S4. After the upper computer connected with the PLC communication inquires the payment record, the PLC controls the screw feeder 5 to perform blanking, and the belt scale 8 is used for measurement, and the weighbridge 10 is used for weighing;

[0037] S5, when the local scale 10 display reaches 90% of the required loading capacity, the screw feeder 5 is controlled by PLC to decelerate,...

Embodiment 2

[0040] S1. When the vehicle is in place, the weighbridge 10 detects the weight of the vehicle, and the user gets off the vehicle to operate the touch screen. At the same time, the weighbridge 10 detects the vehicle weight data and lasts for more than 10 seconds;

[0041] S2. The telescopic rod of the hydraulic cylinder 9 of the weighbridge 10 is retracted, so that the wheel enters the positioning groove 12 to position the vehicle, and the indication of the weighbridge 10 is reset to zero;

[0042] S3. The user inputs the required loading weight through the touch screen and pays the fee;

[0043] S4. After the upper computer connected with the PLC communication inquires the payment record, the PLC controls the screw feeder 5 to perform blanking, and the belt scale 8 is used for measurement, and the weighbridge 10 is used for weighing;

[0044]S5, when the local scale 10 display reaches 90% of the required loading capacity, the screw feeder 5 is controlled by PLC to decelerate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com