Electromagnetic release

A technology of electromagnetic release and magnetic steel, applied in circuits, electrical components, parts of protection switches, etc., can solve problems such as deviation from the neutral position, reduce the operation stability of electromagnetic release, and prevent lateral deviation, Guaranteed stable rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

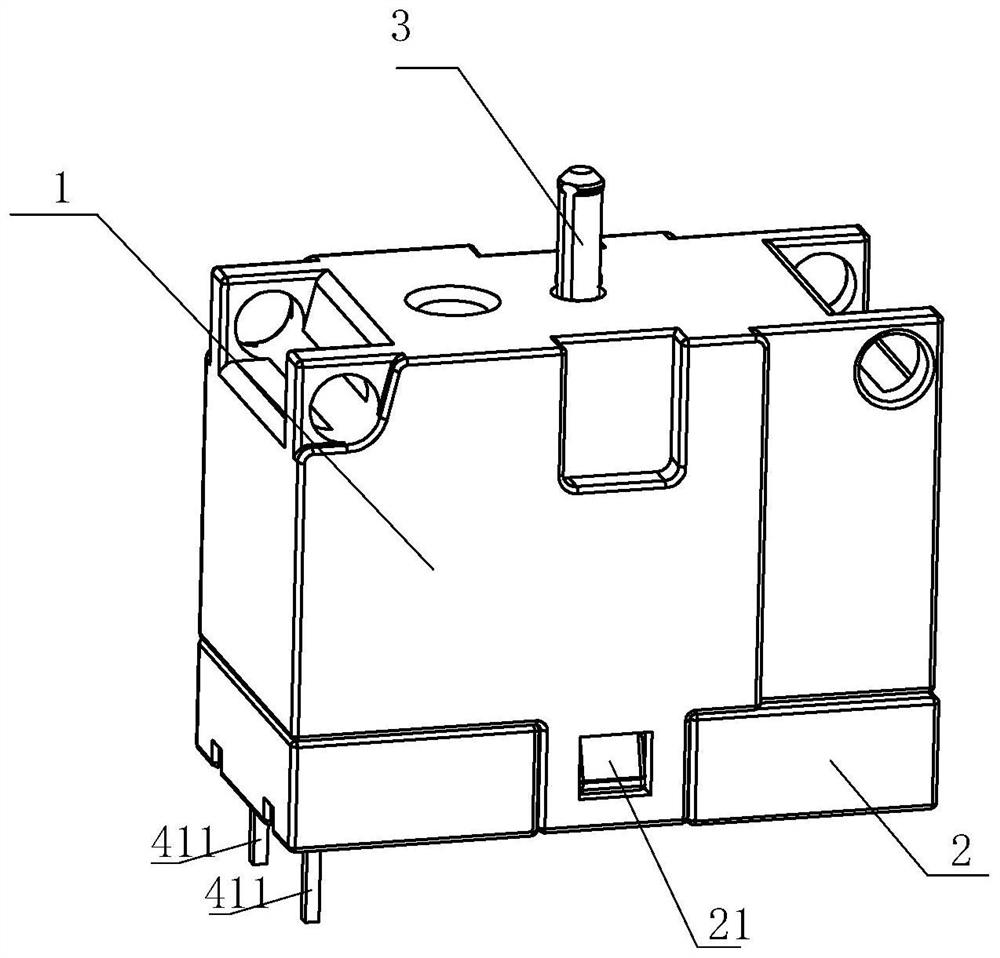

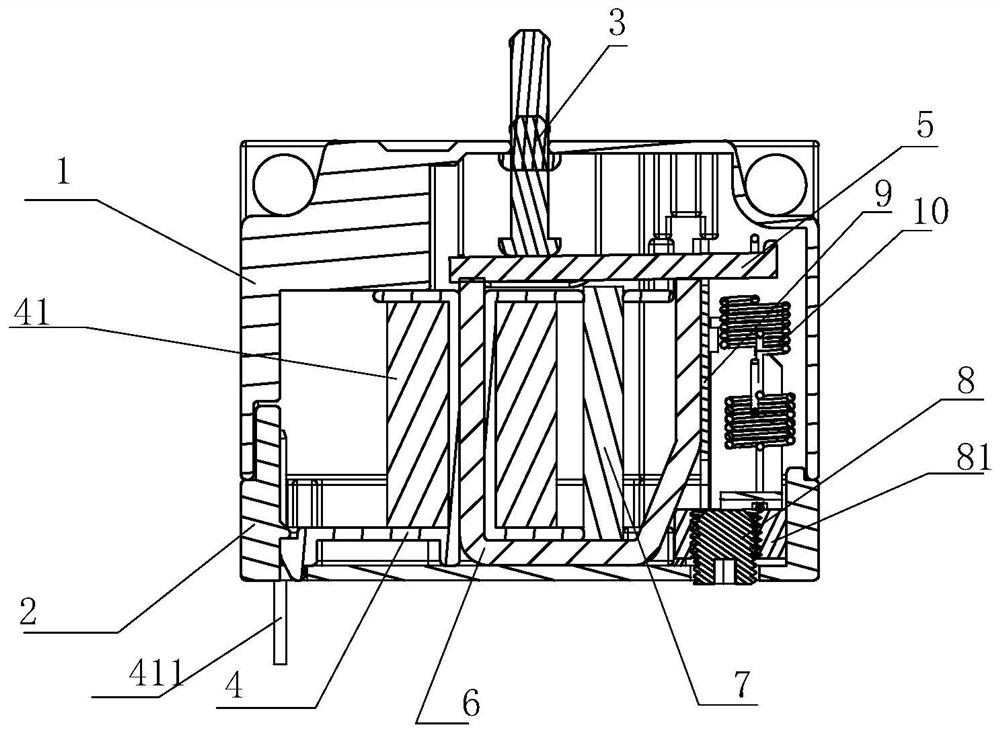

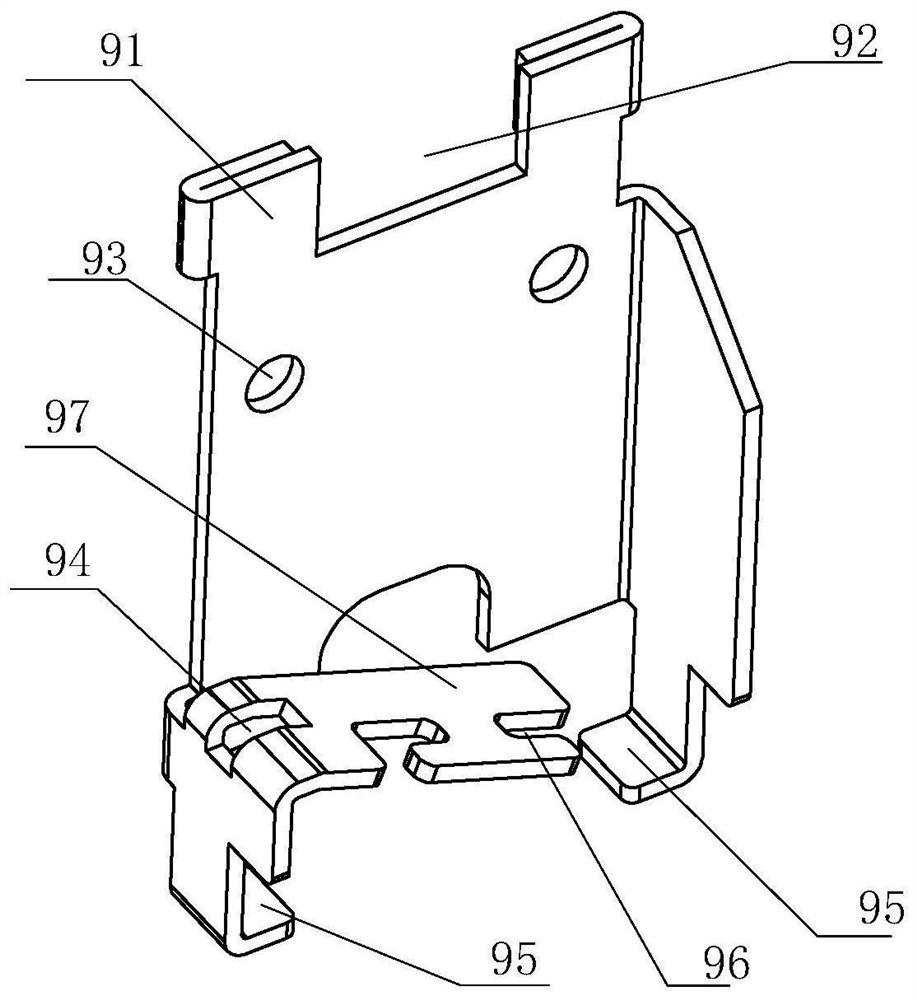

[0022] like Figure 1-7 As shown, an electromagnetic tripper includes a housing 1 and a base 2 to form an accommodation space, and a coil 41 wound on a coil frame 4, a yoke 6, an armature 5, a magnetic steel 7, and a tension spring 10 are arranged in the accommodation space. , a push rod 3 placed on the top of the casing 1 can move upwards under the action of the armature 5, the yoke 6 is U-shaped, the first arm of the yoke 6 extends into the through hole of the bobbin 4, the yoke 6 The pressure reed 9 is fixedly installed on the second arm, the upper end of the pressure reed 9 forms shoulders 91 on both sides, and the shoulders 91 on both sides stretch into the hinge groove of the armature 5, and the top plate of the coil bobbin 4 is close to the positions on both sides of the front end of the armature 5 respectively. Bumps 42 are formed.

[0023] The top plate of the bobbin 4 is provided with an opening 43 , the bottom plate of the bobbin 4 is provided with a slot 44 opposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com