Rotary conveying device and aerated concrete production line

A technology of rotary conveying and conveying line, applied in the direction of conveyor, unloading device, mechanical conveyor, etc., can solve the problems of falling pallets and finished blocks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

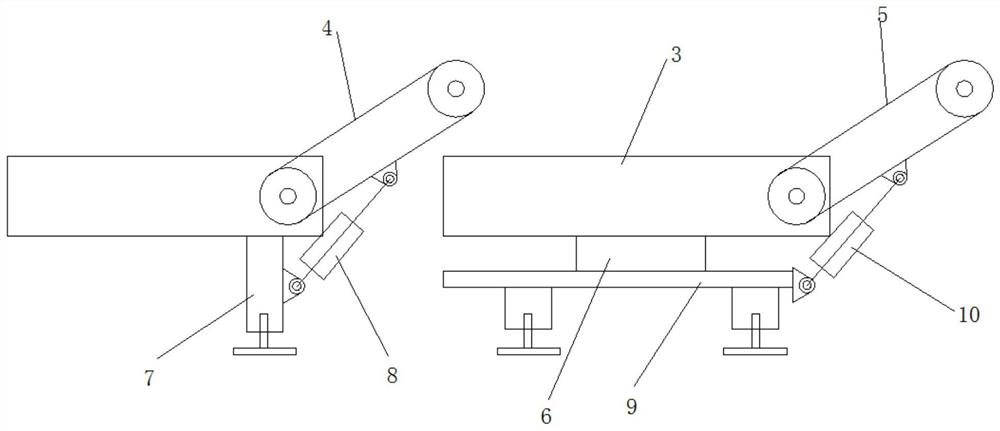

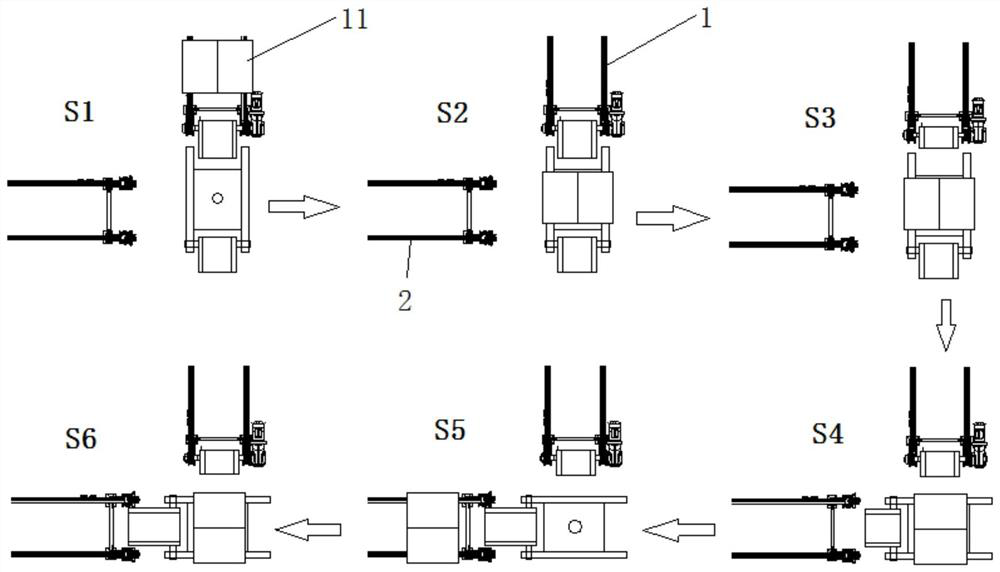

[0040] In the ALC (autoclaved lightweight concrete) finished product off-line section, the finished blocks need to be transported off the line in a direction perpendicular to the pallet conveyor line, so a transition platform is needed to transition the finished blocks from the pallet conveyor line to the block conveyor line.

[0041] When the pallet is on the pallet conveying line, the bottom beam of the pallet is perpendicular to the direction of the conveying line, and it is not easy to drop during transportation. After passing through the transition platform, the bottom beam of the pallet is parallel to the direction of the conveying line, and it is easy to fall during transportation, or the pallet needs to be lengthened To ensure that the pallet is not easy to fall, the distance of the limit device that limits the block is used, which leads to a more complicated structure.

[0042] For this reason, this embodiment provides a rotary conveying device, which can ensure that a...

Embodiment 2

[0065] The difference between this embodiment and the above-mentioned embodiments is that the second driving mechanism includes a first elastic member 12, the first end of the first elastic member 12 is fixedly arranged, the second end is connected with the first delivery unit 4, and the first elastic member 12 The elastic force of is suitable for keeping the second end of the first conveying unit 4 in the raised position. In this embodiment, when the pallet and the finished blocks 11 on the pallet are not on the first conveying unit 4, the elastic force of the first elastic member 12 keeps the second end of the first conveying unit 4 at the raised position, When the pallet and the finished blocks 11 on the pallet are put on the first conveying unit 4, the pallet and the finished blocks 11 on the pallet overcome the elastic force of the first elastic member 12, and press down on the first conveying unit 4, so that The second end of the first conveying unit 4 descends, and the ...

Embodiment 3

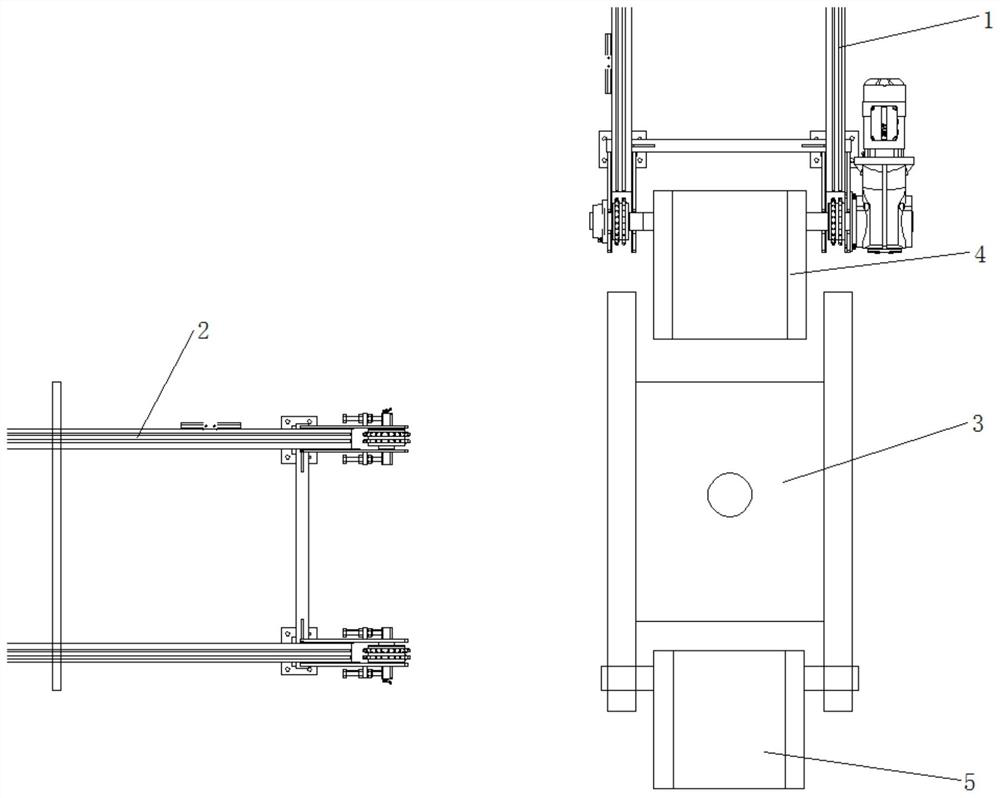

[0072] This embodiment provides an aerated concrete production line, including the rotary conveying device, the pallet conveying line 1 and the block conveying line 2 provided in the above embodiments.

[0073] Wherein the pallet conveying line 1 is perpendicular to the block conveying line 2, the rotating platform 3 is rotatably arranged between the end of the block conveying line 2 and the end of the pallet conveying line 1, and the first conveying unit 4 is arranged on the rotating platform 3 One side of the pallet conveying line 1 is used to convey the pallets to the rotating platform 3; the second conveying unit 5 is set on the other side of the rotating platform 3 and is used to convey the pallets from the rotating platform 3 to the block conveying line 2 on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com