A Coating Rotation Mechanism with Automatic Oscillating Planetary Disk

The technology of a rotating mechanism and a planetary disk is applied in the field of coating rotating mechanism, which can solve the problems of affecting the quality of the coating layer, reducing the coating efficiency, and having impurities in the coating layer, so as to achieve the effect of ensuring the quality of the coating layer and improving the coating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

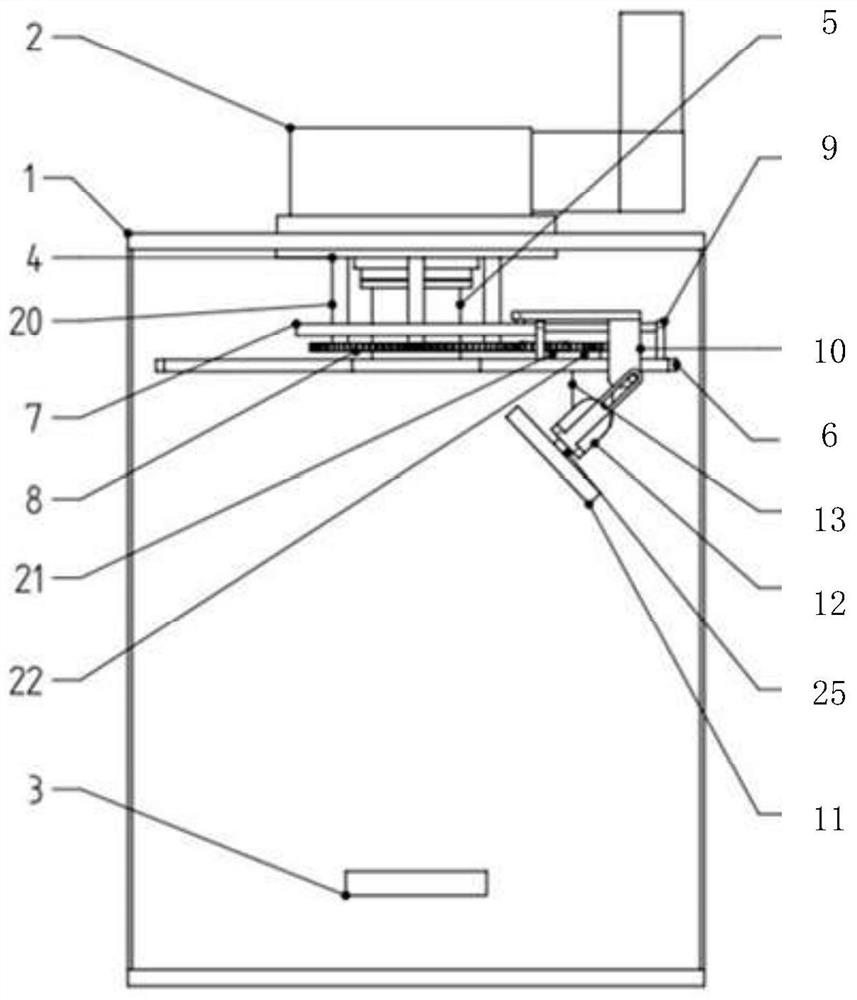

[0015] This embodiment provides a coating rotation mechanism with an automatic swinging planetary disk, and the coating rotation mechanism is used to place a workpiece to be coated, such as a substrate, such as figure 1 As shown, it is installed in the vacuum chamber 1 and driven by a rotary drive device 2 such as a drive motor installed on the top of the vacuum chamber 1, under the action of the evaporation source 3, the uniform coating of the workpiece is realized. The vacuum chamber 1 , the rotary drive device 2 , and the evaporation source 3 are common components in the coating machine, and to avoid redundant description, the present invention omits their specific introduction.

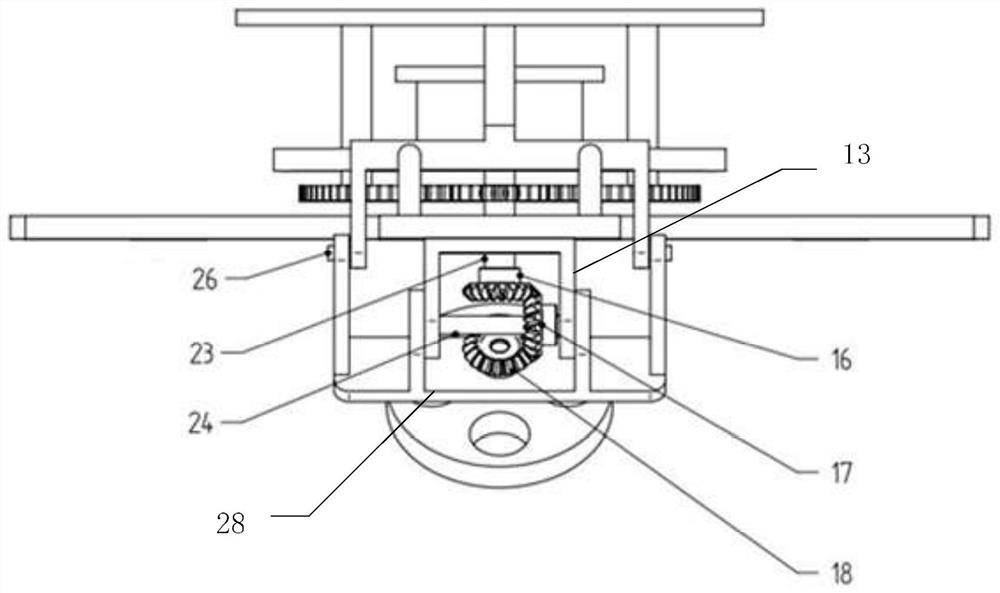

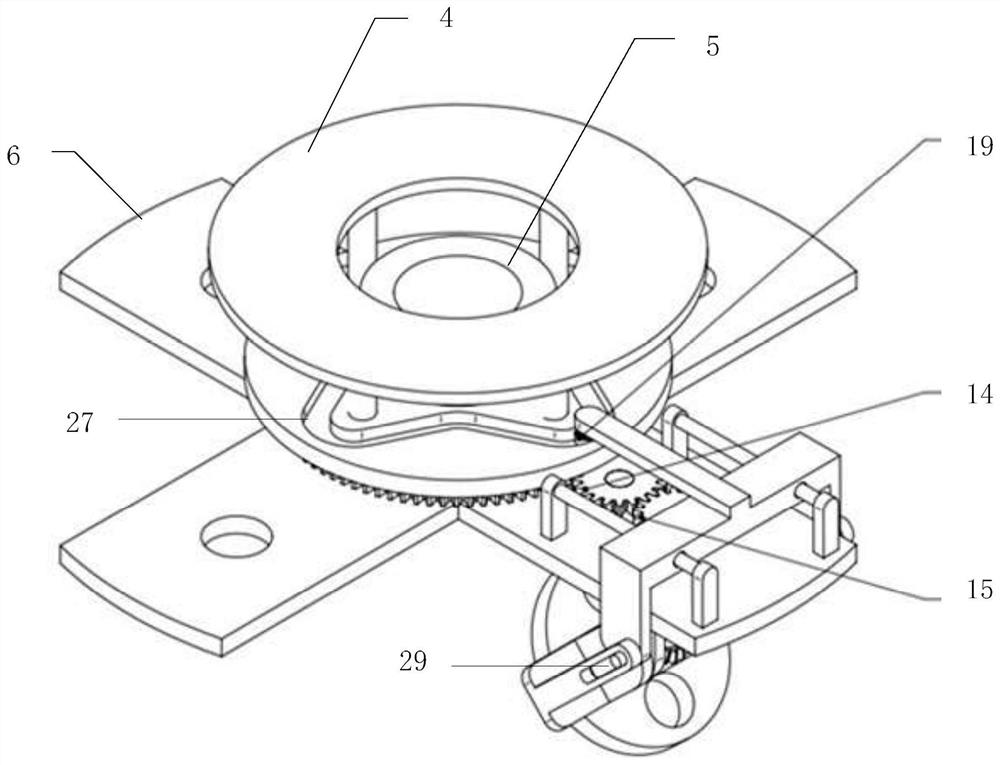

[0016] like Figure 1 to Figure 3 As shown, the coating rotation mechanism provided by this embodiment with the automatic swinging planetary disk may include: a guide wheel 7 , a fixed wheel 8 and a revolving disk 6 that are coaxially arranged in sequence.

[0017] The guide wheel 7 is arranged a...

Embodiment 2

[0025] Figure 4 Another embodiment of the present invention provides a coating rotation mechanism with an automatic swinging planetary disk. like Figure 4 As shown, the structure of the coating rotation mechanism of this embodiment is basically the same as the structure of the coating rotation mechanism of the previous embodiment, the difference is that the automatic swing of the self-rotating plate is realized by the cam and the spring. In the following, in order to avoid redundant description, only the differences are introduced.

[0026]Specifically, in this embodiment, the guide wheel 7 is replaced with a cam 30, the guide track is the outer side of the cam 30, and the bearing 19 is in contact with the outer side and can roll along the outer side. A tension spring 31 may be arranged between the sliding member of the sliding structure and the front end of the guide rail, or a compression spring (not shown) may be arranged between the sliding member of the sliding struct...

Embodiment 3

[0029] Figure 5 Another embodiment of the present invention provides a coating rotation mechanism with an automatic swinging planetary disk. like Figure 5 As shown in the figure, the structure of the coating rotating mechanism of this embodiment is basically the same as that of the coating rotating mechanism of the previous embodiment, the difference is that the coating rotating mechanism is not provided with a guide wheel, and the swing transmission mechanism realizes the automatic rotation of the self-rotating disk 11 through the crank and the connecting rod. swing. In the following, in order to avoid redundant description, only the differences are introduced.

[0030] In this embodiment, the sliding structure 10 is connected with the first driven wheel 14 through the crank 41 and the connecting rod 42 . One end of the crank 41 is rotatably connected to the first driven wheel 14 through the fixing frame, the other end is rotatably connected to one end of the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com