Y-shaped supporting device for temporary supporting of prefabricated wall

A temporary support and support device technology, applied in the field preparation of pillars and building components, construction, etc., can solve problems such as hidden dangers, inability to adhere closely, difficult to fully synchronize operations, etc., to achieve small footprint, efficient and convenient use, The effect of a high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

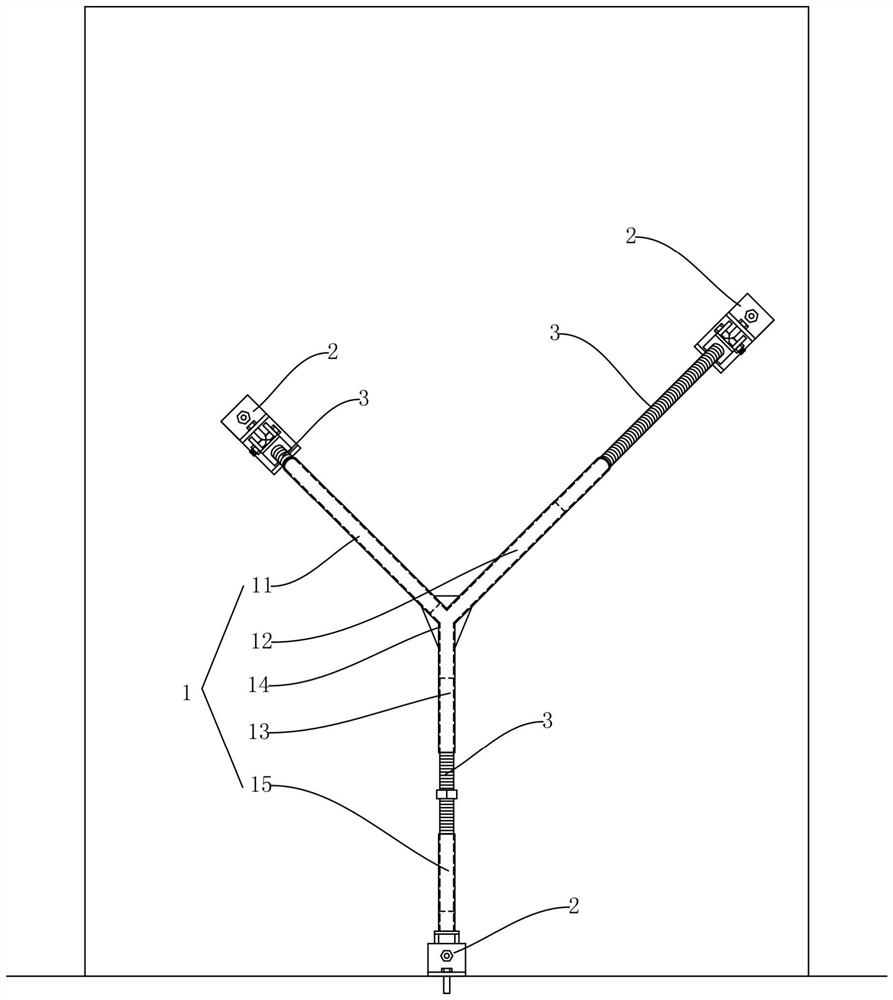

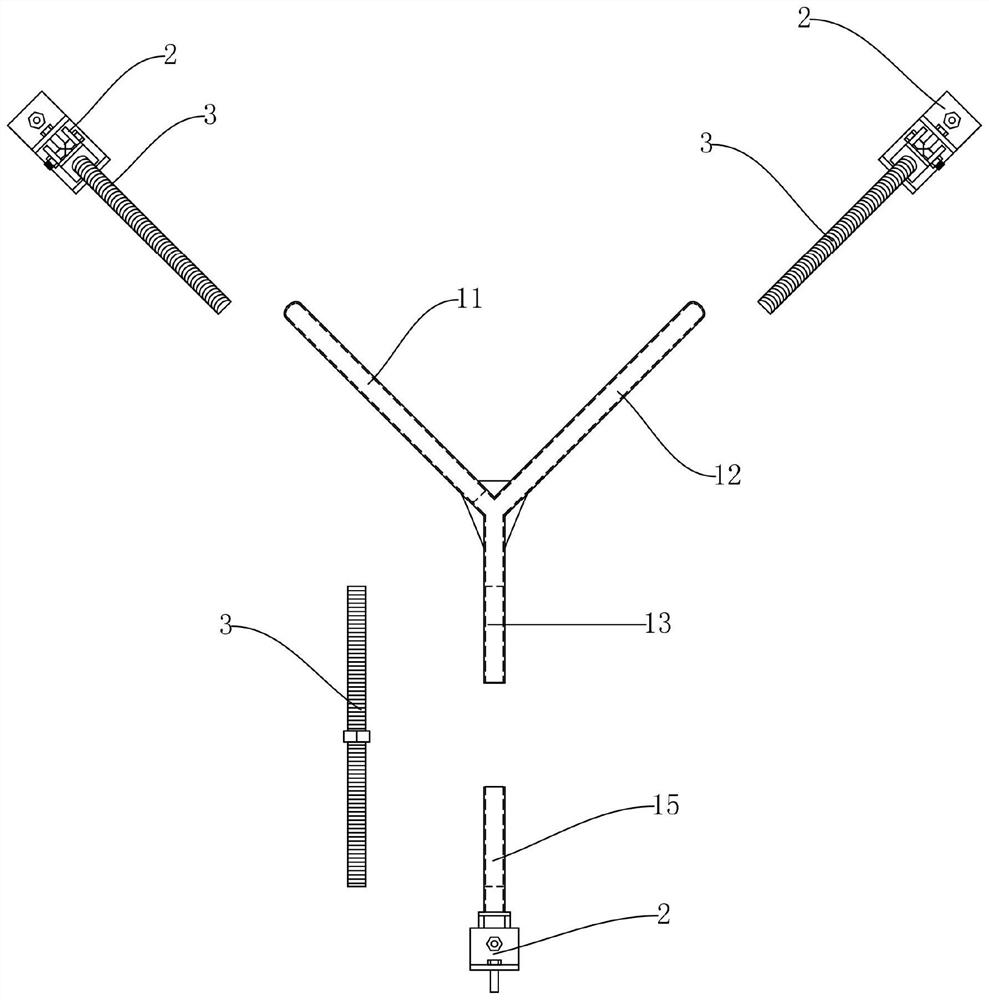

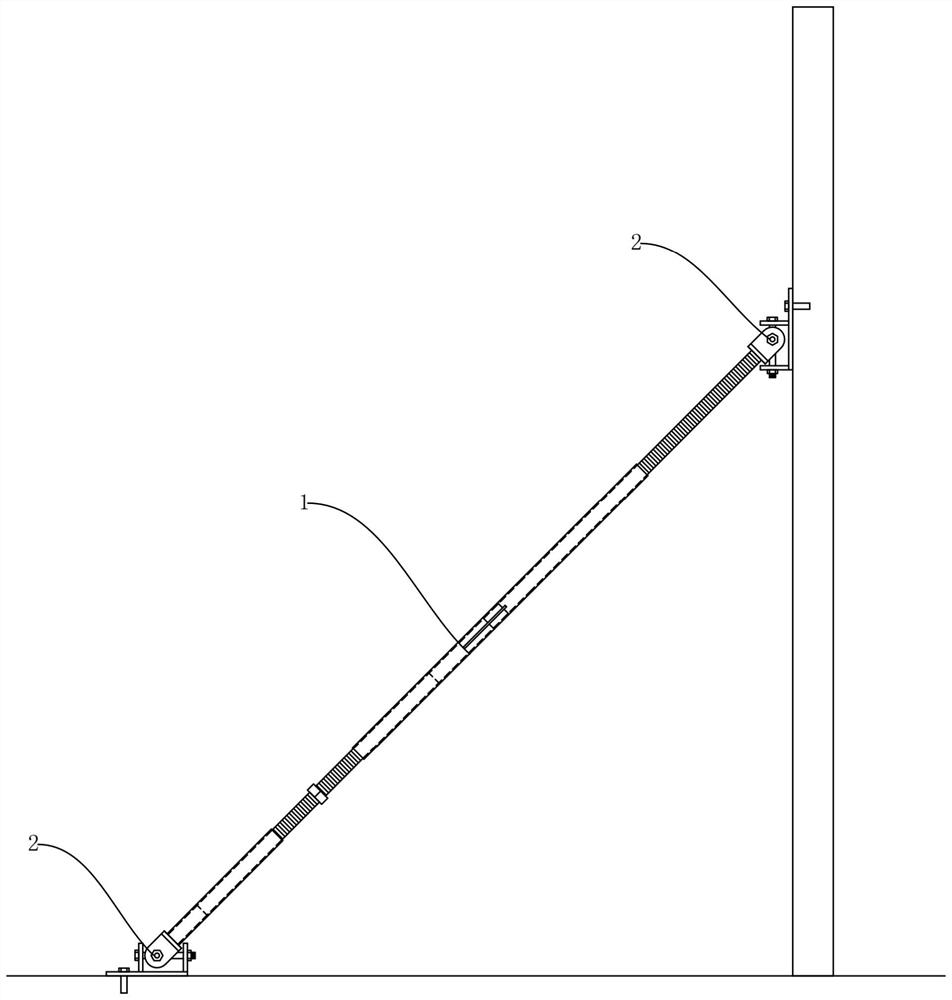

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing, and these accompanying drawings are all simplified schematic diagrams, only illustrate the basic structure of the present invention in a schematic way, and the direction of this specific implementation is based on figure 1 Orientation is standard.

[0019] Such as Figure 1 to Figure 3 As shown, a Y-shaped support device for temporary support of prefabricated walls includes a Y-shaped support rod 1, three fixed supports 2 and three telescopic adjustment rods 3, and the Y-shaped support rod 1 includes a first support rod 11 , the second support rod 12, the third support rod 13, and the telescopic adjustment rod 3 are respectively fixed on the fixed support 2, and the first support rod 11, the second support rod 12, and the third support rod 13 are respectively connected with a telescopic adjustment rod 3 .

[0020] The Y-shaped support rod 1 also includes a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com