Drill rod power head device, circulating device and drilling machine

A technology of circulation device and power head, which is applied to rotary drilling rigs, drilling tools, earthwork drilling and mining, etc., and can solve problems such as difficulty in drilling wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

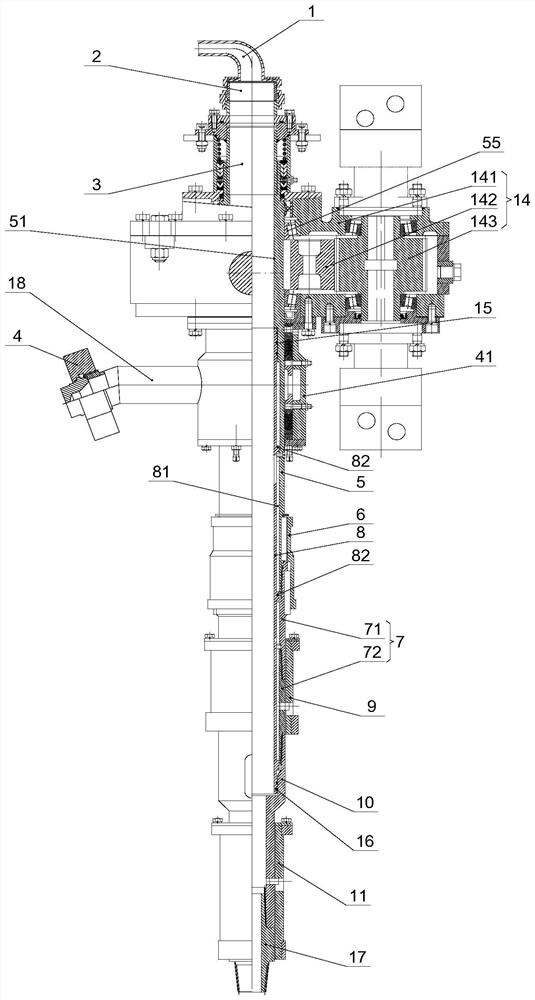

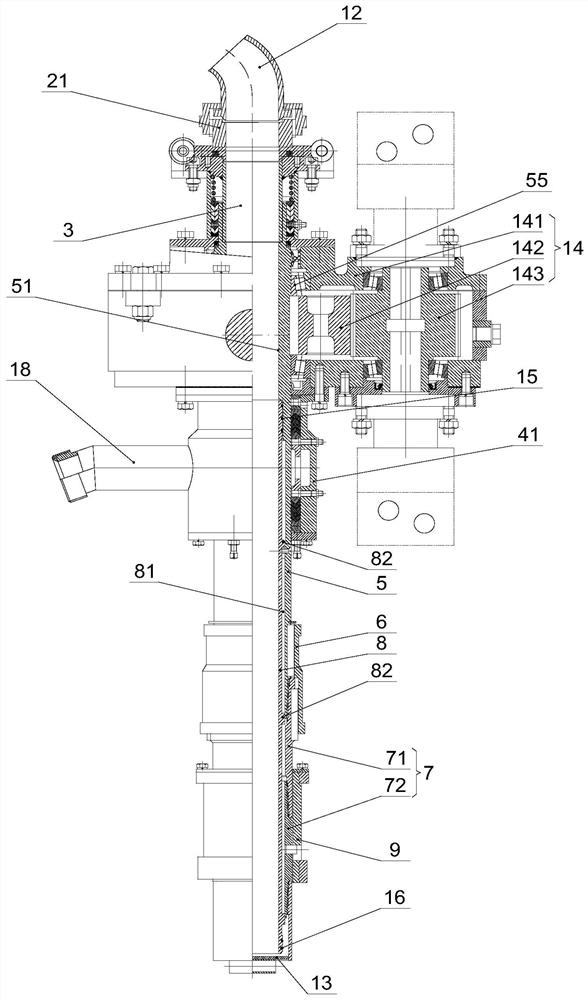

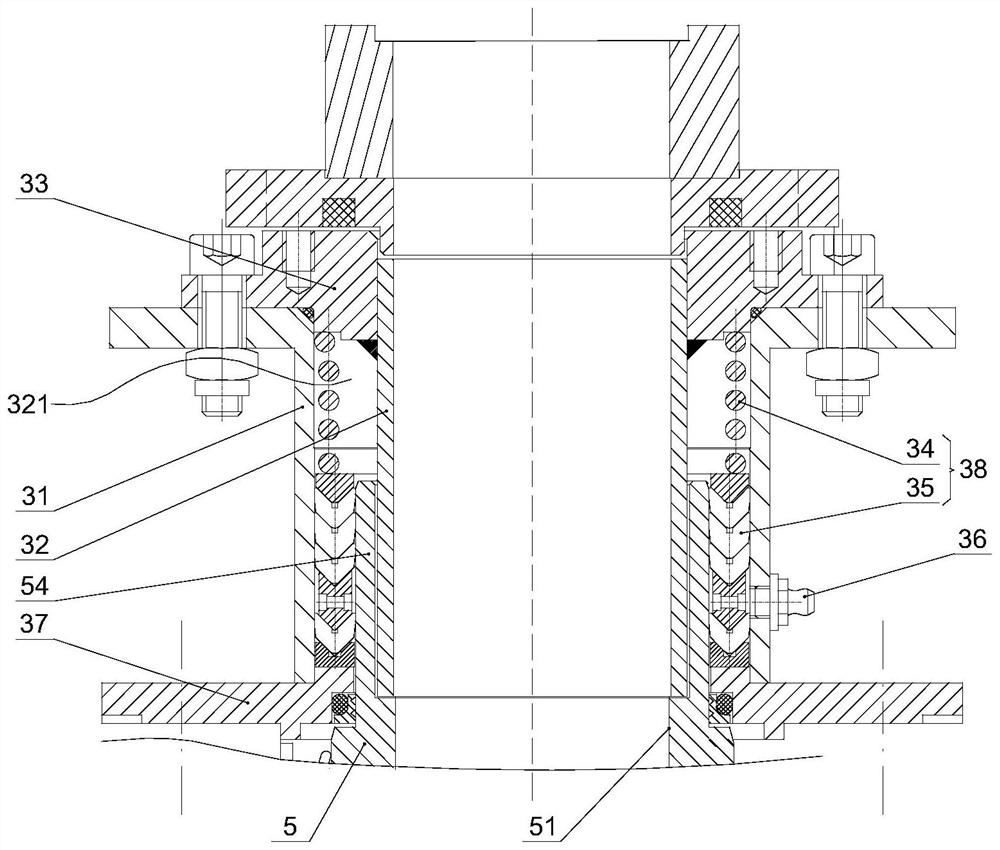

[0062] The invention provides a drill pipe power head device, such as figure 1 , figure 2 with Figure 5 As shown, the drilling head unit includes a power mechanism 14 and a circulation device; the circulation device includes: a center pipe 5, an inner pipe 8 and an air intake pipe 18; the center pipe 5 is installed on the power mechanism 14, and the power mechanism 14 can drive the center pipe 5 rotation; the inner pipe 8 is arranged in the central pipe 5, and the first annular space 81 is arranged between the inner pipe 8 and the central pipe 5, and the upper end of the inner pipe 8 is sealed with the inner wall of the central pipe 5; the air inlet pipe 18 and the first ring Hole 81 communicates; In the case that the lower end of central pipe 5 is connected to the positive circulation drill pipe, the central hole of inner pipe 8 communicates with the central hole of positive circulation drill pipe; In the case of circulating drill pipe, the first annulus 81 communicates w...

Embodiment 2

[0092] The present invention provides a circulation device, which is applied to the above-mentioned drill pipe head device, such as figure 1 , figure 2 with Figure 5 As shown, the circulation device includes: a central pipe 5, an inner pipe 8 and an air intake pipe 18; the inner pipe 8 is arranged in the central pipe 5, and a first annular space 81 is provided between the central pipe 5 and the inner pipe 8; the air intake pipe 18 It communicates with the first annulus 81; when the lower end of the center pipe 5 and the lower end of the inner pipe 8 are connected to the reverse circulation drill pipe, the first annulus 81 communicates with the drill pipe annulus of the reverse circulation drill pipe, and the inner pipe The center hole of 8 communicates with the center hole of the inner pipe of the reverse circulation drill pipe; when the lower end of the center pipe 5 is connected with the positive circulation drill pipe, the center hole of the inner pipe 8 communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com