Overflow and blowout prevention drilling device and method thereof

A drilling device and anti-overflow technology, applied in drilling equipment and methods, wellbore/well valve devices, drill pipes, etc., can solve problems such as the lack of anti-overflow and blowout functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

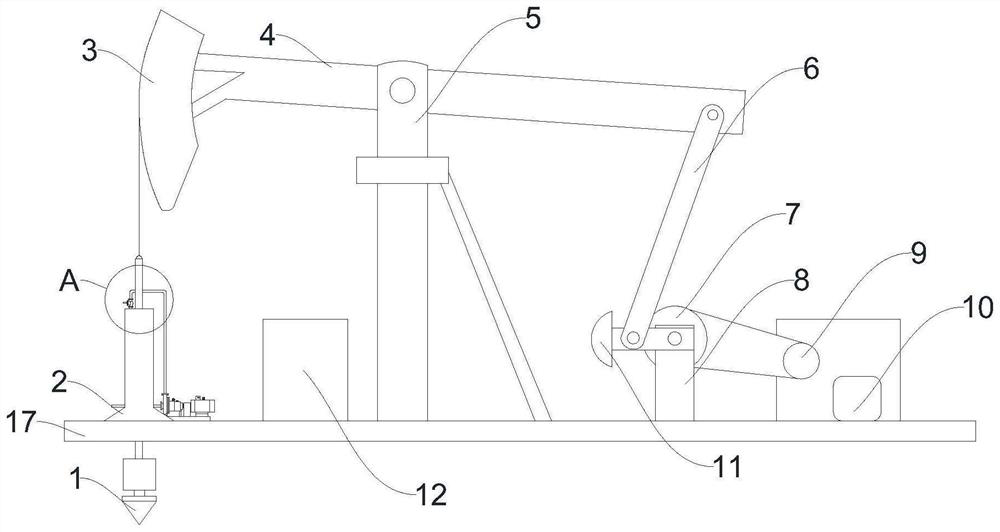

[0049] Please refer to Figure 1-Figure 7 , the present embodiment provides an overflow and blowout prevention drilling device, which has the function of preventing overflow and blowout.

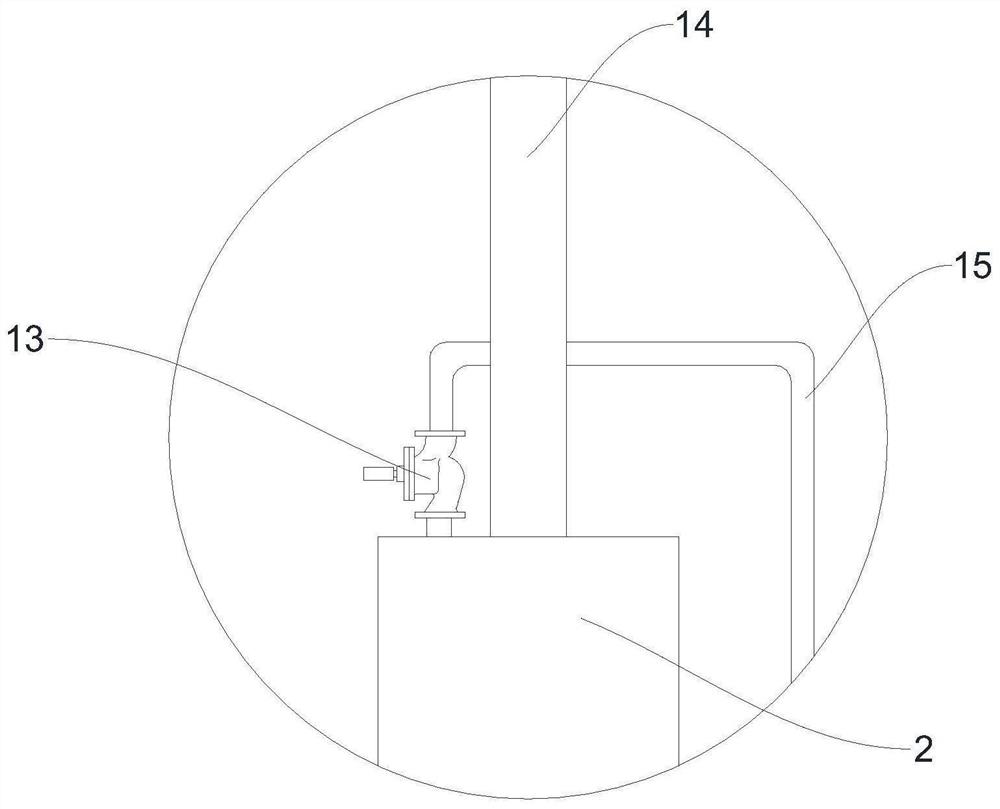

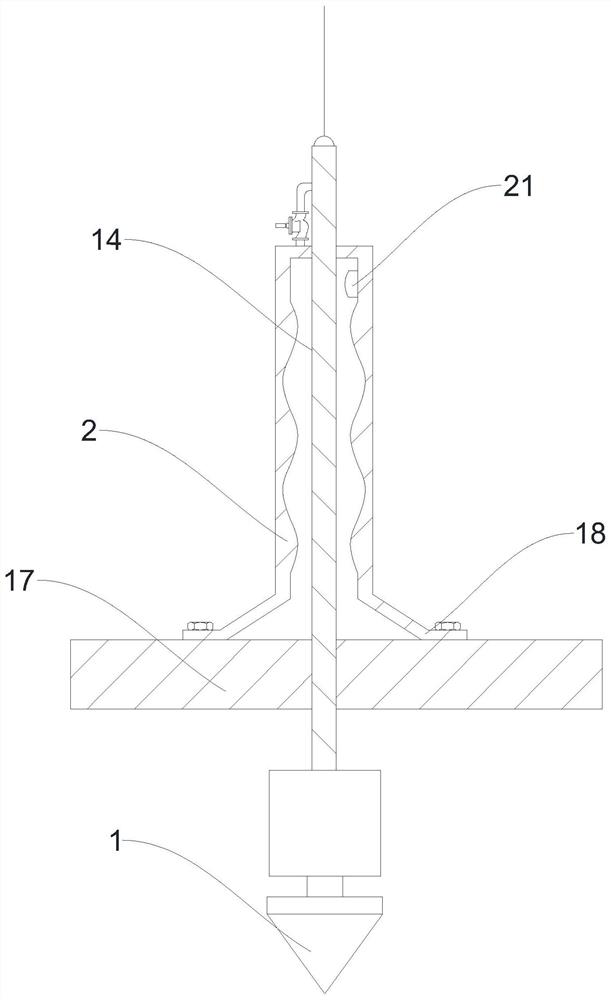

[0050] A drilling device for preventing overflow and blowout, comprising a horizontally placed drilling machine base plate 17, and also includes a fixed support rod 5, the above-mentioned fixed support rod 5 is arranged on the upper side of the above-mentioned drilling machine base plate 17, and the above-mentioned fixed support rod The upper side of the pendulum 5 is horizontally hinged with a pendulum 4, one end of the above-mentioned pendulum 4 is connected with a drilling main engine, the other end of the above-mentioned pendulum 4 is connected with a power assembly that drives it to swing, and the lower side of the above-mentioned drilling main engine 3 is provided with The drill rod 14 that cooperates with it, the lower side of the above-mentioned drill rod 14 runs through the lower si...

Embodiment 2

[0069] Please refer to Figure 1-Figure 7 , the present invention provides a method for realizing a drilling device for preventing overflow and blowout, comprising the above-mentioned drilling device, comprising the following steps:

[0070] Drilling process: connect the power supply of the power assembly, the power assembly drives the pendulum 4 to swing, and the pendulum 4 drives the main drilling machine to swing during the swinging process. to punch holes;

[0071] Level 1 anti-overflow: When the drill bit 1 is drilling, the internal fluid pressure gushes outwards when the pressure of the internal fluid is too high. The second pressure sensor 20 transmits the signal to the central processing module 12, the central processing module 12 inflates the expansion air bag 19, and the expansion air bag 19 expands the air bag cover 16 to achieve the first-level sealing purpose in the well;

[0072] Secondary anti-overflow: due to the unevenness of the inner area of the wellhead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com