A technical method of casing drilling through the goaf

A technology of casing drilling and process method, which is applied in drilling equipment and methods, drilling equipment, earthwork drilling and production, etc., and can solve problems such as drilling fluid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

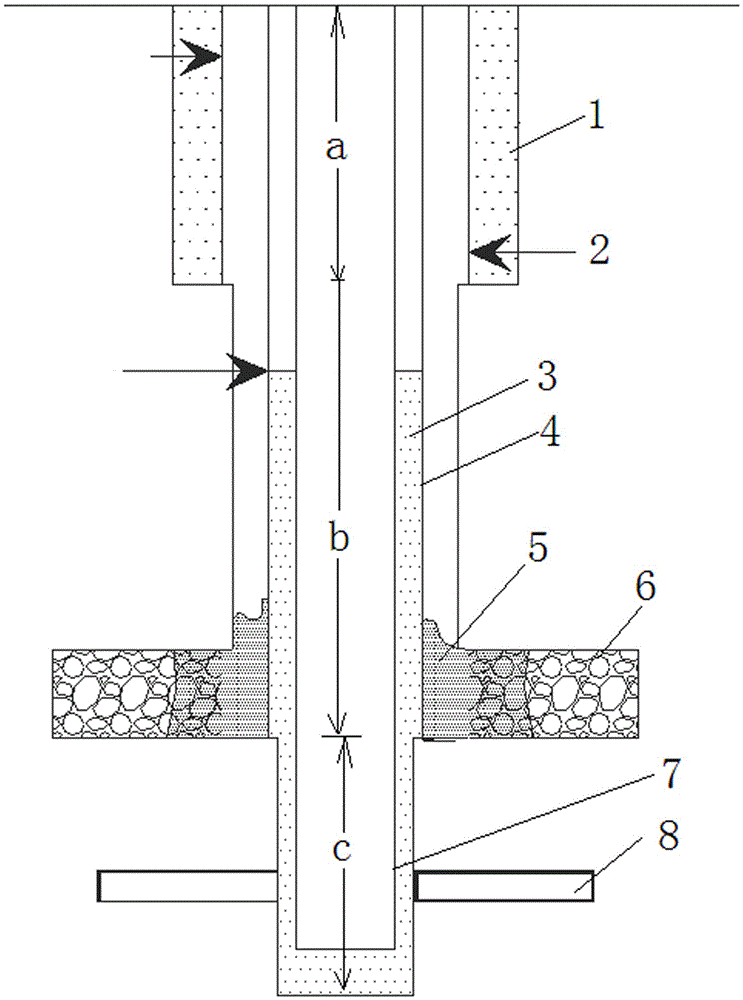

[0015] Such as figure 1 As shown, in order to ensure that the goaf can be successfully traversed, the surface drilling adopts a three-split shaft structure.

[0016] First hole: use Φ374.70mm first-hole drill bit to drill the final hole 10m below the weathered bedrock, lower the Φ273.05mm surface casing 2 to the bottom and cement the well with cement 1, and return the cement 1 to the surface.

[0017] Second hole: use the casing instead of the drill pipe to drive the Φ193.70mm second hole drill bit to drill the casing drilling process so that the second hole bit can drill to the coal seam floor of the goaf. After the second hole is drilled, replace the casing of the drill pipe The pipe remains in the wellbore as a technical casing, and cementing is carried out on the well wall (contact surface of the water-conducting fracture zone) between the technical casing and the goaf.

[0018] Three openings: Continue to use the drill pipe to drive the Φ171.50mm three opening drill bit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com