Anti-icing structure of inlet guide vane of aero-engine and inlet guide vane

A technology of aero-engines and inlet guide vanes, which is applied in the direction of machines/engines, liquid fuel engines, and parts of pumping devices for elastic fluids, etc., which can solve problems such as engine performance degradation and achieve the effect of maintaining aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

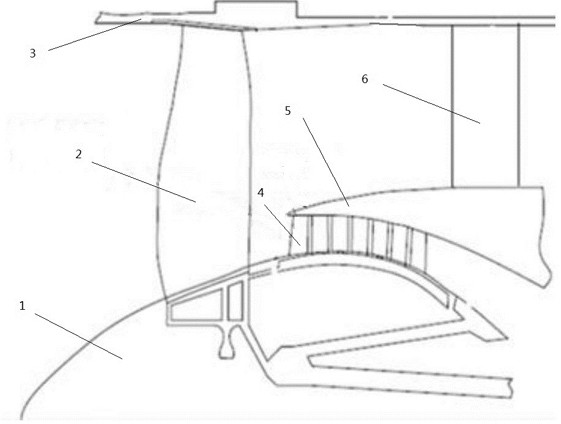

[0050] The embodiment of the present invention provides an anti-icing structure of the inlet guide vane 4 of an aero-engine, such as figure 1 Shown is a schematic diagram of the internal structure of an aero-engine, which includes an air intake cone 1, a fan blade 2, a fan case 3, an inlet guide vane 4, a splitter ring 5 and an outlet guide vane 6, wherein the fan blade 2 is connected to the inlet Air cone 1 , inlet guide vane 4 and outlet guide vane 6 are all arranged downstream of fan blade 2 , and splitter ring 5 is arranged between inlet guide vane 4 and outlet guide vane 6 . The anti-icing structure can be used on the inner icing surface of the aeroengine, especially on the icing surface of the inlet guide vane 4 .

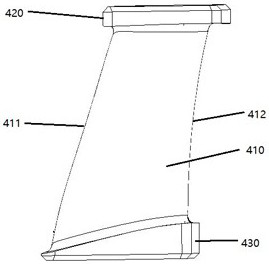

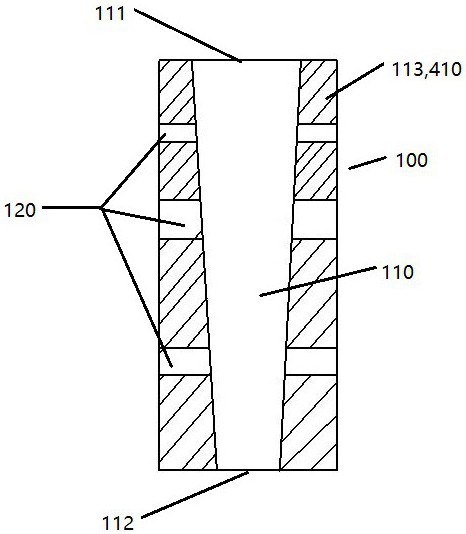

[0051] Such as image 3As shown, the anti-icing structure includes an installation part 100 and a deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com