A kind of welding assembly method of side plate of breaker

A welding assembly and breaking hammer technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as easy deformation, achieve the effects of reducing deformation, ensuring precision, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

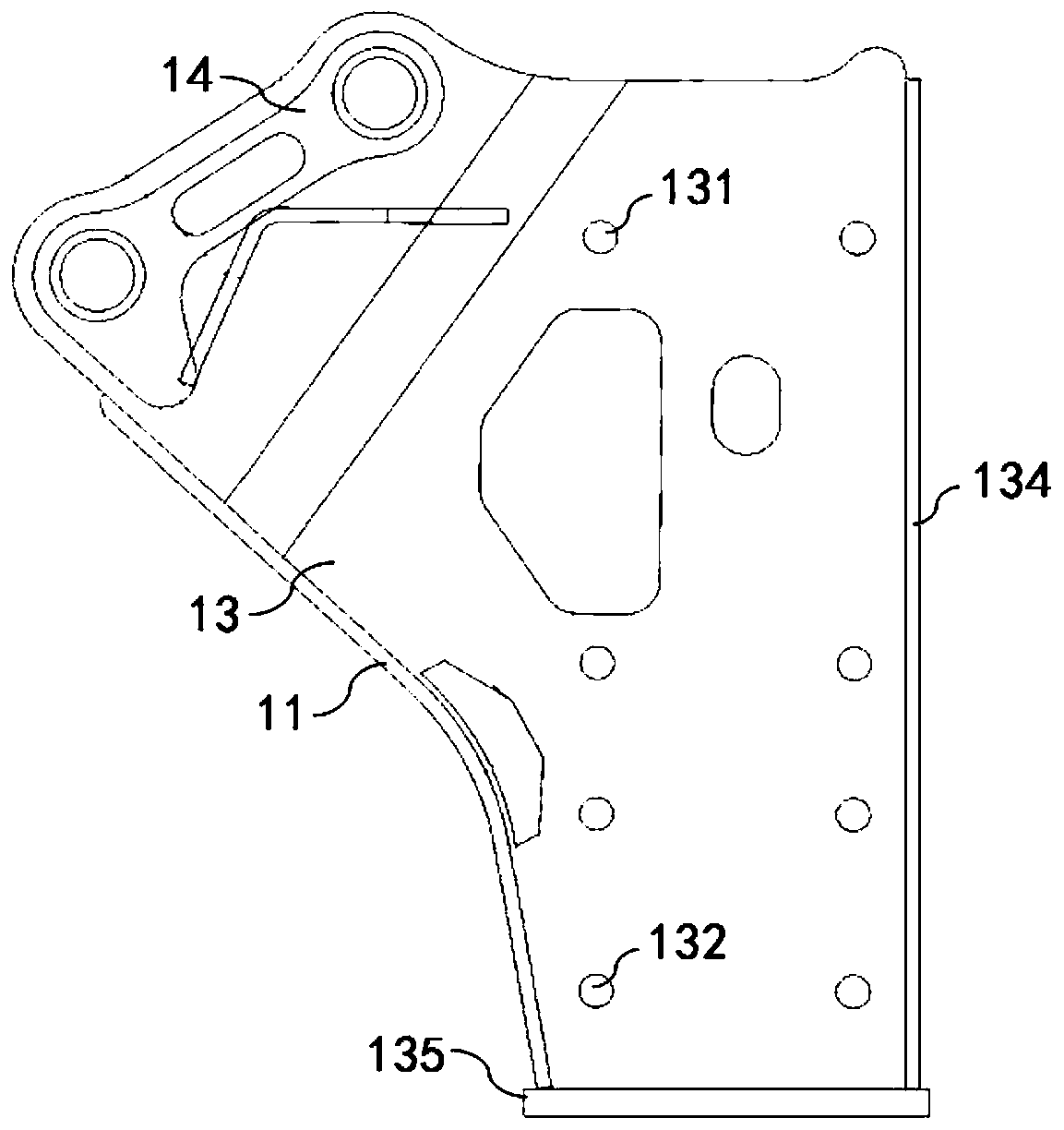

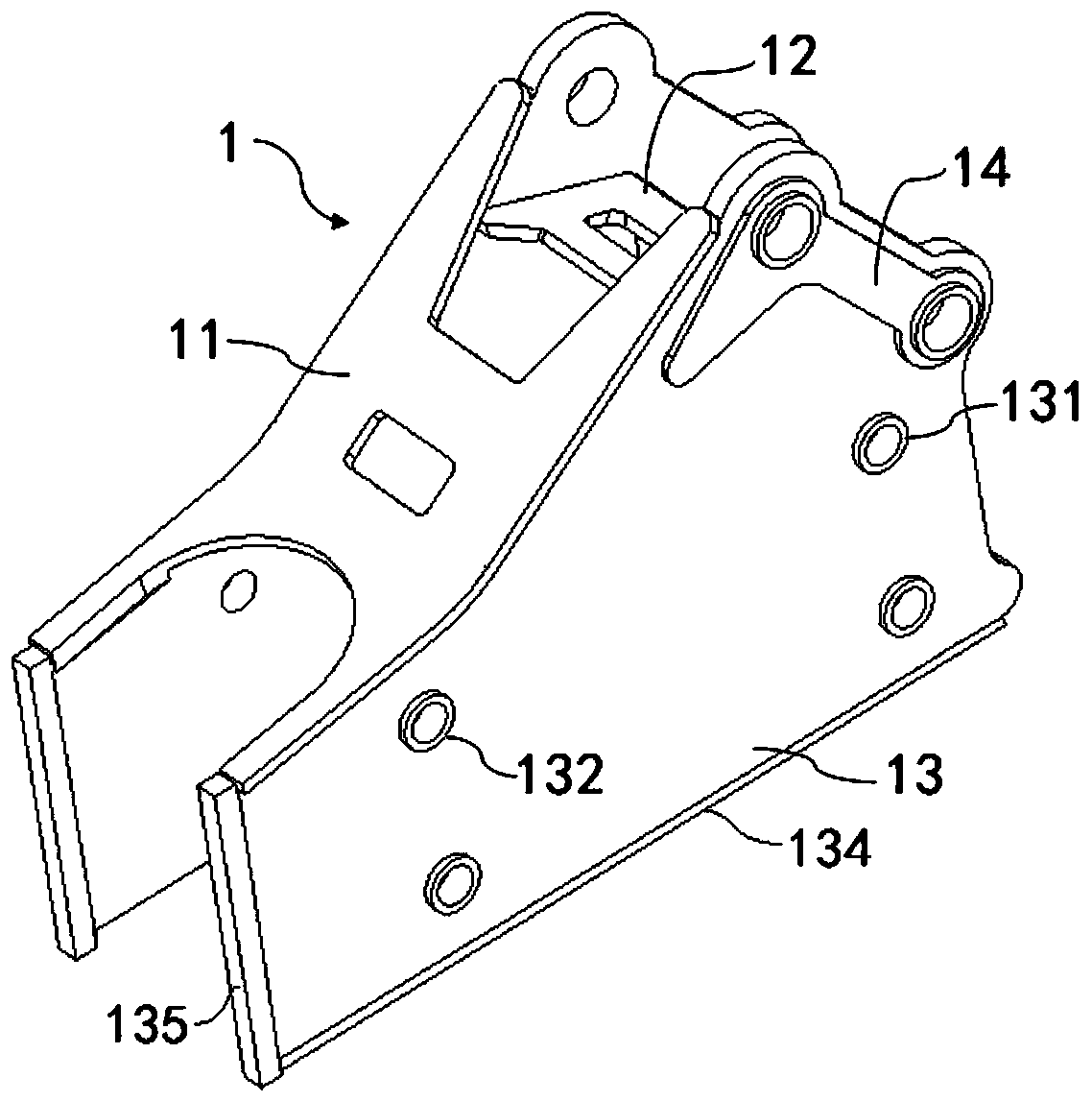

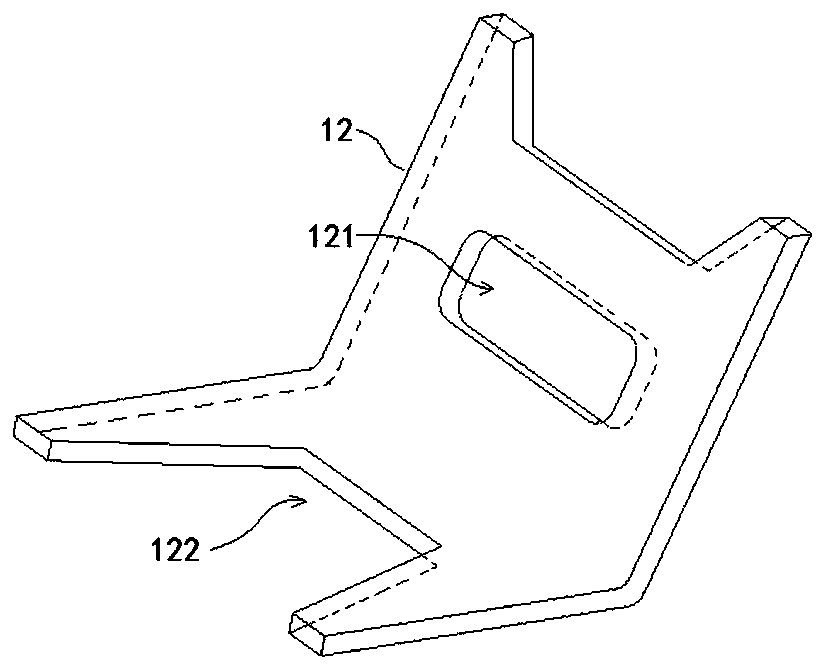

[0048] combine Figure 5 , Figure 6 , a welding and assembling method of the side plate of the breaker in this embodiment, the side plate is bent and flattened by the flattening mechanism 4, and the welding and assembly process of the side plate is performed by the welding fixing mechanism 2. Wherein, the compacting mechanism 4 comprises a compacting cylinder 41, an upper bracket 42 and a compacting platform 45, the upper bracket 42 is supported above the compacting platform 45 by a briquetting guide rod 43, and the compacting cylinder 41 is vertically fixed on the upper bracket 42, the piston rod of the pressing cylinder 41 is connected with the pressing block body 44, the lower surface of the pressing block body 44 is flat, and the side plate 13 can be bent or flattened by using the cushion block 46 and the rectangular pressing rod 47. operate. Such as Figure 5 As shown, a rectangular pressing bar 47 is placed on the lower side of the side plate 13, the side plate 13 is...

Embodiment 2

[0054] The improvement of the method for welding and assembling the side plate of the breaking hammer in this embodiment is that a collar 24 is arranged on the outer wall of the box body 21, and the inner diameter of the collar 24 is equal to the size of the through hole 23, and is in line with that of the through hole 23. The through holes 23 are arranged coaxially. The box body 21 can be set as a hollow structure, and the collar 24 can increase the structural strength. After being installed in the positioning shaft, it can play a main supporting role, and the through hole 23 will not be deformed after long-term use. In this embodiment, the distance between the baffle plate 25 and the positioning plate 22 is 1.4 times the thickness of the side plate 13 of the hammer.

Embodiment 3

[0056] The improvement of the method for welding and assembling the side plate of the breaker in this embodiment is that a collar 24 is provided on the outer wall of the box body 21, the inner diameter of the collar 24 is smaller than the size of the through hole 23, and the collar 24 can Put it into the through hole 23 and weld it to the inner wall of the through hole 23 . In this embodiment, the positioning shaft is directly supported by the collar 24, which has high structural strength. The distance between the baffle plate 25 and the positioning plate 22 is 1.6 times of the thickness of the side plate 13 of the breaking hammer.

[0057] Further, there are four through holes 23 at each end of the box body 21 , and there are two on the upper and lower sides of the positioning plate 22 , and the positioning plate 22 is located in the area surrounded by the four through holes 23 . That is, at the same end of the side wall of the box body 21 , two through holes 23 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com