Fluid conveying system and control method thereof

A fluid conveying system and fluid conveying technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of waste of material and liquid, low efficiency, dripping pollution, etc., to ensure efficiency, avoid damage, avoid the effects of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

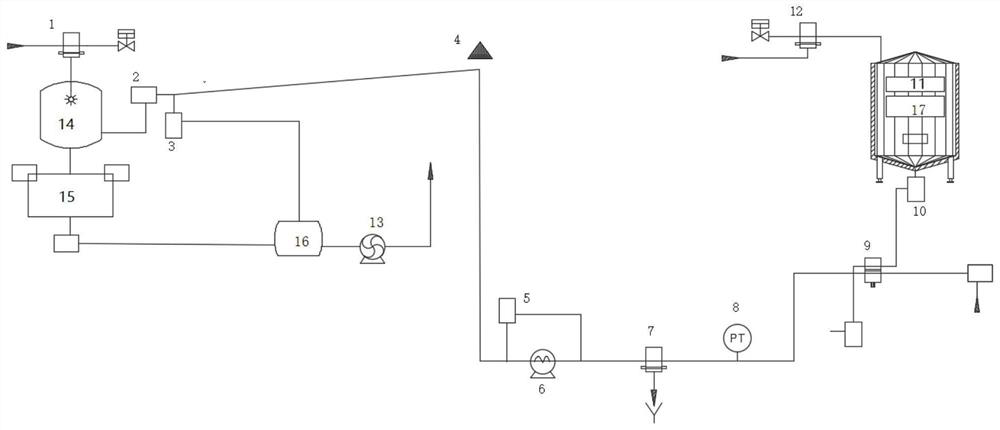

[0054] This embodiment provides a fluid delivery system. In one embodiment, as figure 1 As shown, the fluid delivery system includes a fluid delivery target, a fluid delivery source 11 .

[0055] Among them, the fluid delivery target includes a material cylinder 14 and a fluid output unit 15. The material cylinder 14 is connected with a first air intake control unit 1 and a feed valve 2, and the first air intake control unit 1 is suitable for controlling the feeding of sterile air into the material cylinder. , the fluid output unit 15 communicates with a cleaning return pipeline; the fluid delivery source 11 is provided with a feed valve 9, and the feed valve 9 is connected to the feed valve 2 through a feed pipeline; the feed pipeline is provided with the highest point 4, the highest The height of point 4 is higher than that of the feed valve 2, and there is a drainage branch connected between the feed pipeline close to the feed valve 2 and the cleaning return pipeline, and ...

Embodiment 2

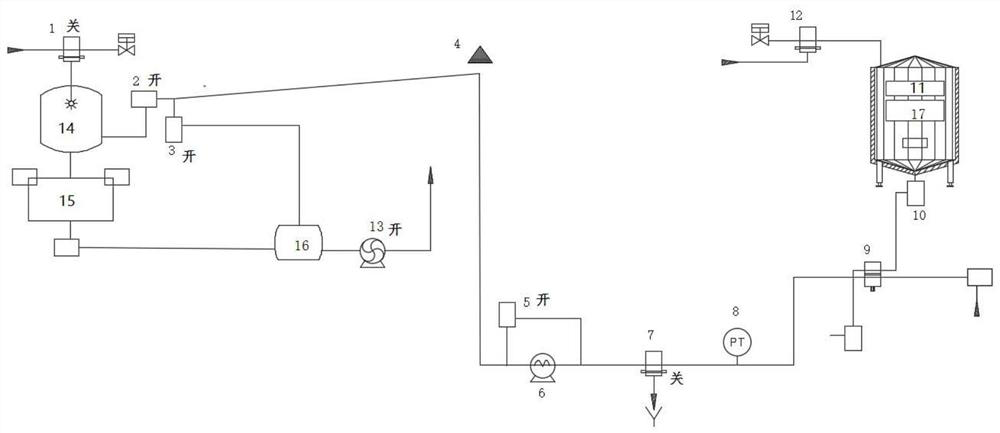

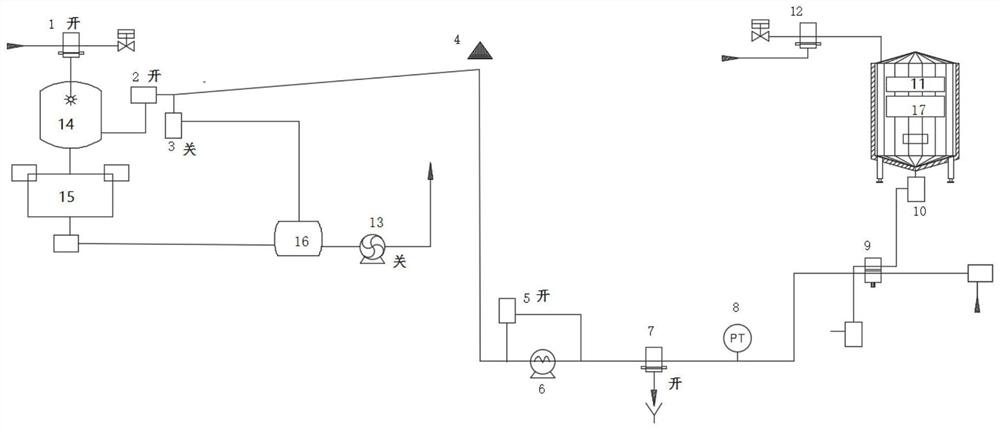

[0072] This embodiment provides a control method using a fluid delivery system, and the control method is used in the fluid delivery system provided in Embodiment 1. In one embodiment, the control method includes the following steps:

[0073] S1: Discharge the water from the highest point 4 to the feed valve 2;

[0074] S2: Control the opening of the first air intake control unit 1 and the feed valve 2, so that the feed pipeline is filled with sterile air;

[0075] S3: Control the opening of the feed valve 9 and the top air discharge valve 3, so that the feed liquid in the fluid delivery source 11 enters the feed pipeline, and the feed liquid pushes the sterile air to be discharged through the feed top air discharge valve 3.

[0076] In this embodiment, the water in the feeding pipeline is discharged first, and the temperature of the feeding pipeline can be lowered during the process of filling the feeding pipeline with sterile air, thereby avoiding the impact of sterile hot ...

Embodiment 3

[0102] This embodiment provides a control method using a fluid delivery system, and the control method is used in the fluid delivery system provided in Embodiment 1. The difference between this embodiment and embodiment 2 is:

[0103] Step S1 includes: controlling the feed valve 2, turning on the cleaning return pump 13, and discharging the water from the highest point 4 to the feed valve 2.

[0104] In this embodiment, step S1 can drain the hot water in the second branch section by increasing the backflow delay function in the last link of cleaning and disinfection, without manual operation by the operator, and also realizes the manual operation error prevention function.

[0105] Specifically in this embodiment, the following steps are included:

[0106] Step S1: control the feed valve 2 and the cleaning return pump 13 to turn on, and discharge the water from the highest point 4 to the feed valve 2. Increase the time-delay function of reflux and evacuation after cleaning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com