Method and system for calibrating parallelism of incongruous turning light pipe based on double-mirror splicing

A calibration system and calibration method technology, which is applied in the field of parallelism calibration method and system of anisotropic deflection light pipe, can solve the problems of high cost, low comprehensive calibration accuracy of double theodolite mutual aiming method, high risk of calibration with large aperture plane mirror method, etc. problems, achieve cost reduction, improve calibration efficiency, and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

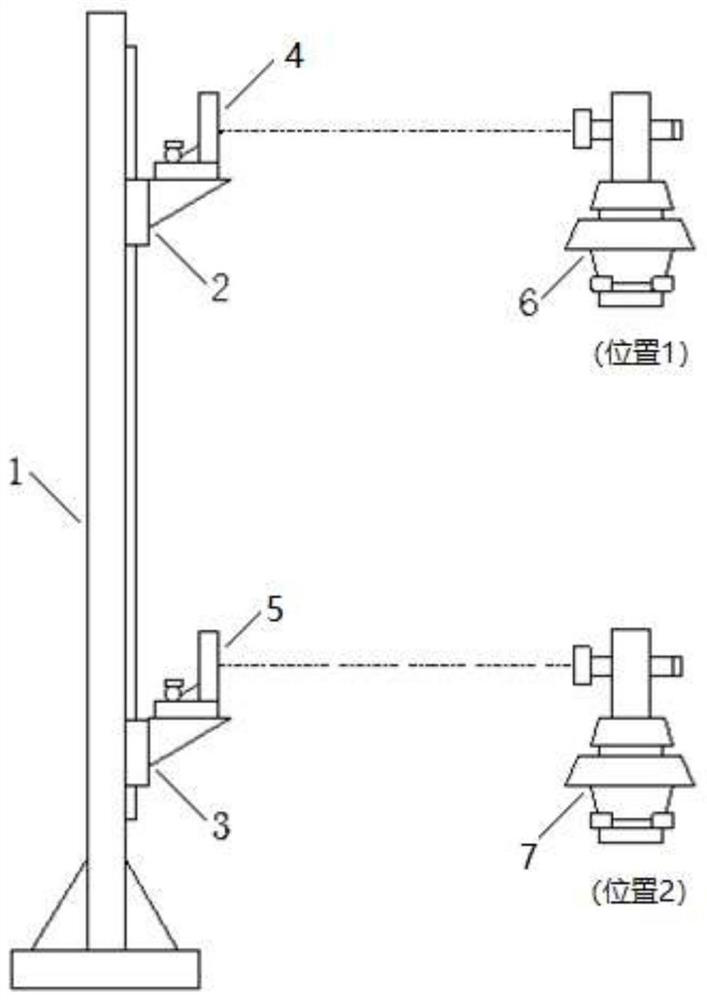

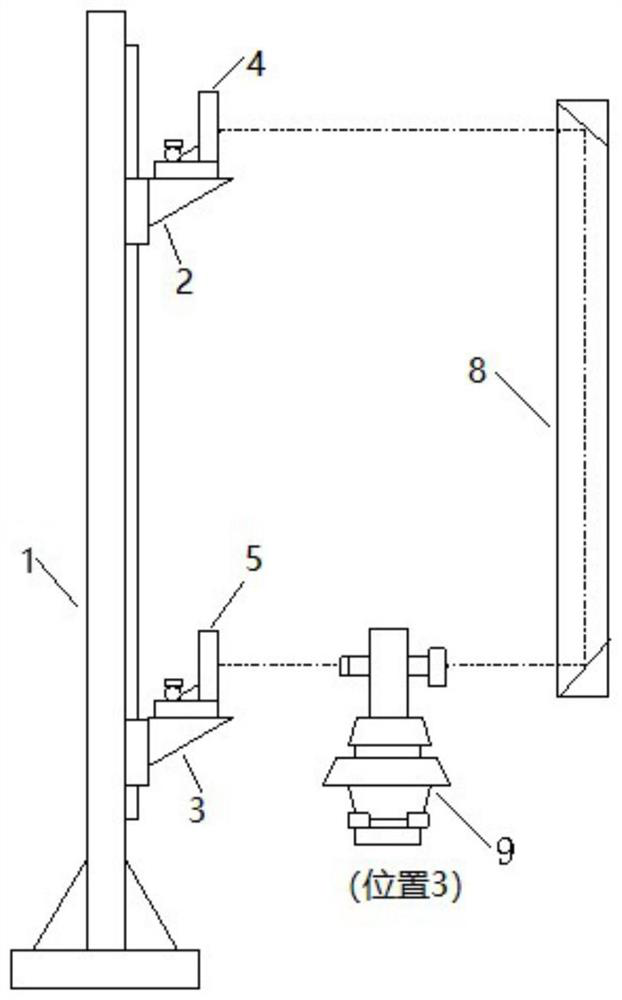

[0042] The present invention provides an anisotropic deflection light pipe parallelism calibration system based on double-mirror splicing. The system includes: a vertical one-dimensional guide rail 1, a first sliding translation stage 2, a second sliding translation stage 3, a first plane Mirror device 4, second plane mirror device 5, high-precision gyro theodolite (position 1) 6, high-precision gyro theodolite (position 2) 7, anisotropic refracting light pipe to be tested 8, high-precision gyro theodolite (position 3 )9.

[0043] The length of the vertical one-dimensional guide rail 1 is 1200 mm to 1300 mm, and the double tracks are arranged in parallel. The first sliding translation platform 2 and the second sliding translation platform 3 are driven by screw screws on the vertical one-dimensional guide rail 1, and the straightness of the guide rail is better than 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com