A wire-disconnecting device based on rapid motor maintenance

A fast, clamping mechanism technology, used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of stator damage and large load, and achieve the effect of stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

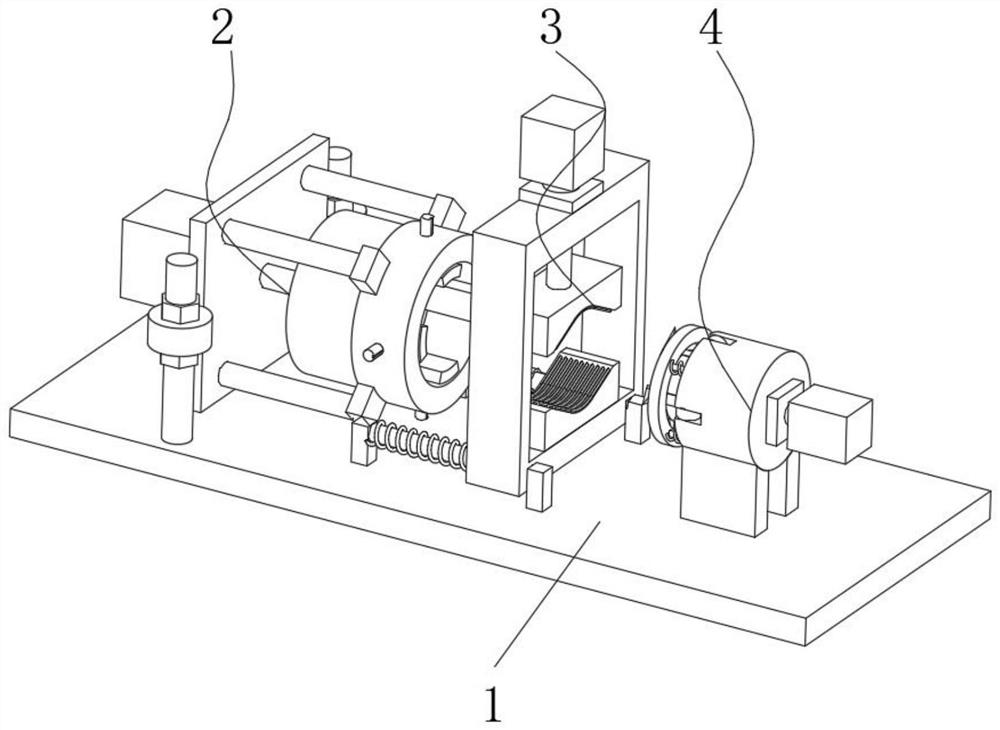

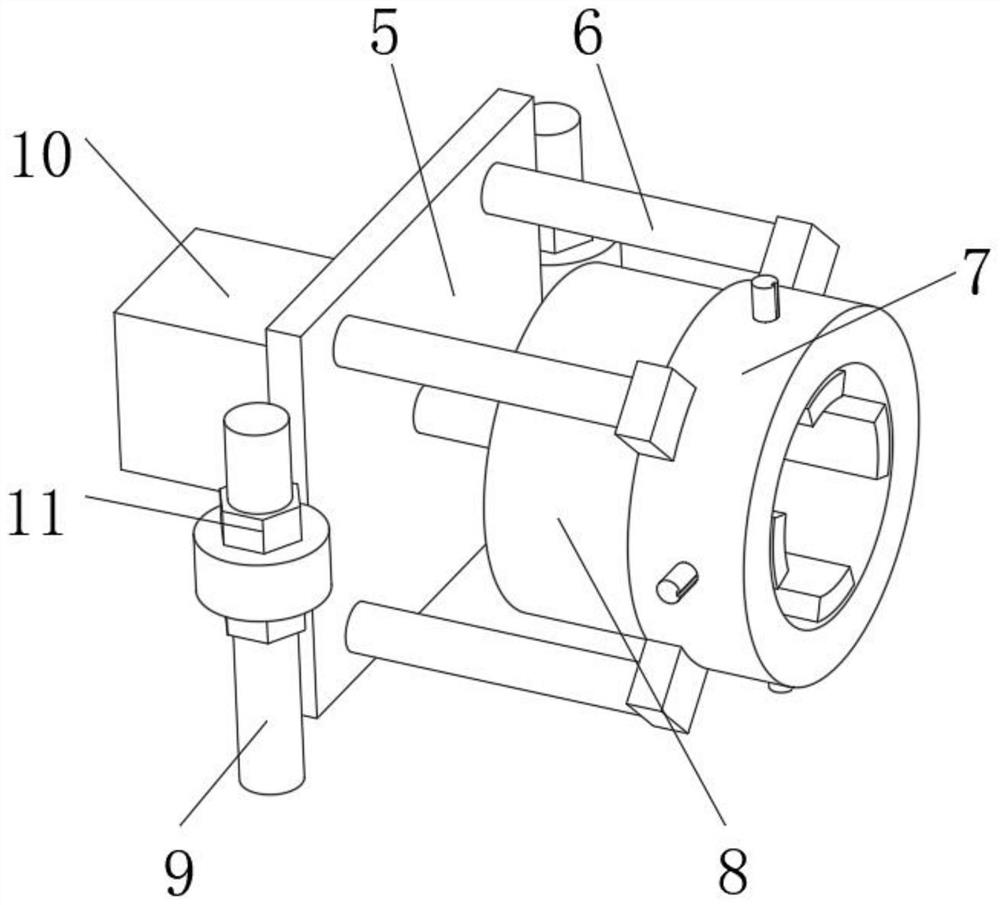

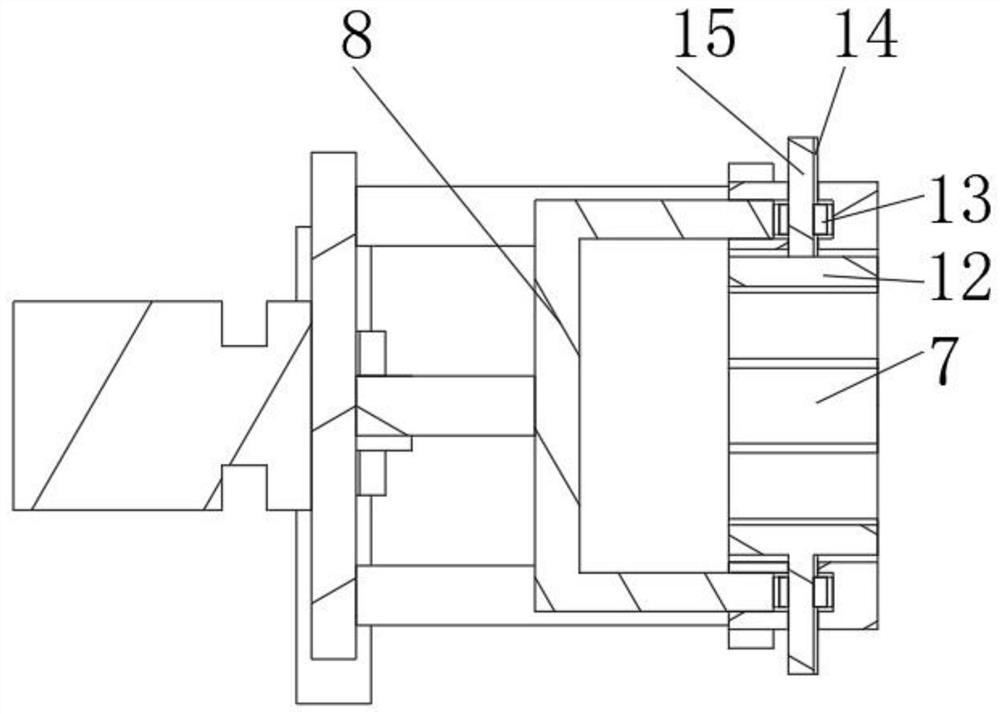

[0038] A wire removal device based on motor quick maintenance, such as Figure 1-3As shown, including a workbench 1, the top outer wall of the workbench 1 is sequentially provided with a shaping mechanism 2, a clamping mechanism 3 and a separation mechanism 4, and the shaping mechanism 2 includes a support plate 5, an outer ring 7 and an inner ring 8, Both outer walls of the support plate 5 are movably connected with lifting screws 9. The lifting screws 9 are fixed on the top outer wall of the workbench 1 by bolts. Adjust the nut 11, the outer wall of one side of the support plate 5 is fixed with the rotary motor 10 by bolts, the output shaft of the rotary motor 10 is welded to the outer wall of the axis of the inner ring 8, and the outer ring 7 is fixedly connected to the support plate 5 through four support rods 6 , the outer ring 7 is slidingly connected with the inner ring 8, and the inner wall of the outer ring 7 is connected with four shrinking screws 15 through threads....

Embodiment 2

[0042] A wire removal device based on rapid motor maintenance, in order to solve the problem of coil detachment device; this embodiment makes the following improvements on the basis of Embodiment 1, such as Image 6 As shown, the outer wall of the separating hook 30 is integrally formed with a shrinking inclined surface protrusion 29, and the inner wall of the limit ring 24 is rotatably connected with a shrinking roller 28 corresponding to the position of the shrinking inclined surface protrusion 29; when the hydraulic cylinder 23 is in the shrinking state, After it pulls the coil out of the stator, when the shrinking slope protrusion 29 reaches the shrinking roller 28, its limiting action will rotate the four separating hooks 30 closer to each other, so that they are separated from the coil, so that the coil can be more closely connected with the device. A good separation completes the collection of coils.

Embodiment 3

[0044] A wire removal device based on rapid motor maintenance, in order to further solve the separation problem between the coil and the device; this embodiment makes the following improvements on the basis of Embodiment 2, such as Figure 6-8 As shown, a blocking ring 27 is slidably connected to one side of the outer wall of the limit ring 24 through four sliding rods 26 . It is a tapered type, and the outer side of the tapered shape is an inclined surface, and the inner side is a flat surface; since the four separation hooks 30 in the embodiment 2 are contracted, the coil is affected by gravity and will still hang on the separation hook 30 at the top, Manual separation is also required. In this embodiment, the blocking ring 27 is provided. When the separating hook 30 is contracted to the other side of the coil and contacts the blocking ring 27, the retracting roller 28 cooperates with the retracting slope protrusion 29. During the process of approaching each other, on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com