Manufacturing method of high-surface-quality extra-thick plate

A manufacturing method and a technology of extra-thick plates, which are applied in the field of steel rolling production, can solve problems such as difficult to meet the size requirements, achieve uniform performance, improve surface quality, and prevent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] In this embodiment, 250mm / 350mm*2000mm*2400-4800mm Q345R and Q345qE billets are selected, and the rolling of steel plates with a thickness specification ≥ 50 mm is completed in a 5000mm wide and thick plate double-stand rolling mill production line. The specific rolling process control is as follows:

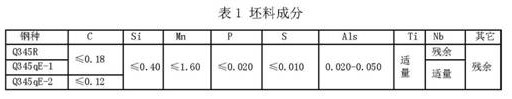

[0033] Select a representative component system that is prone to watermarks for rolling, and the components are shown in Table 1:

[0034]

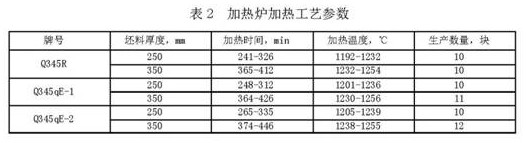

[0035] The billet heating process is used to produce low-alloy steels with different composition systems. The process execution is shown in Table 2:

[0036]

[0037] The actual value of the descaling pressure during the descaling process is between 20.5-21.5MPa.

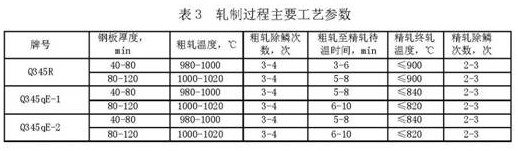

[0038] Process control: the thickness of the rolled steel plate is 50-120mm, the rough rolling temperature is 980-1020°C, the rough rolling is descaled 3-4 times, the thickness of the intermediate billet after the rough rolling is ≥1.5, it is rolled after being warme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com