Dumbbell bearing automatic assembling device

A technology for automatic assembly of devices and bearings, which can be applied to devices that apply liquid to surfaces, assembly machines, metal processing, etc., and can solve the problems of uneven grease application, high assembly costs, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

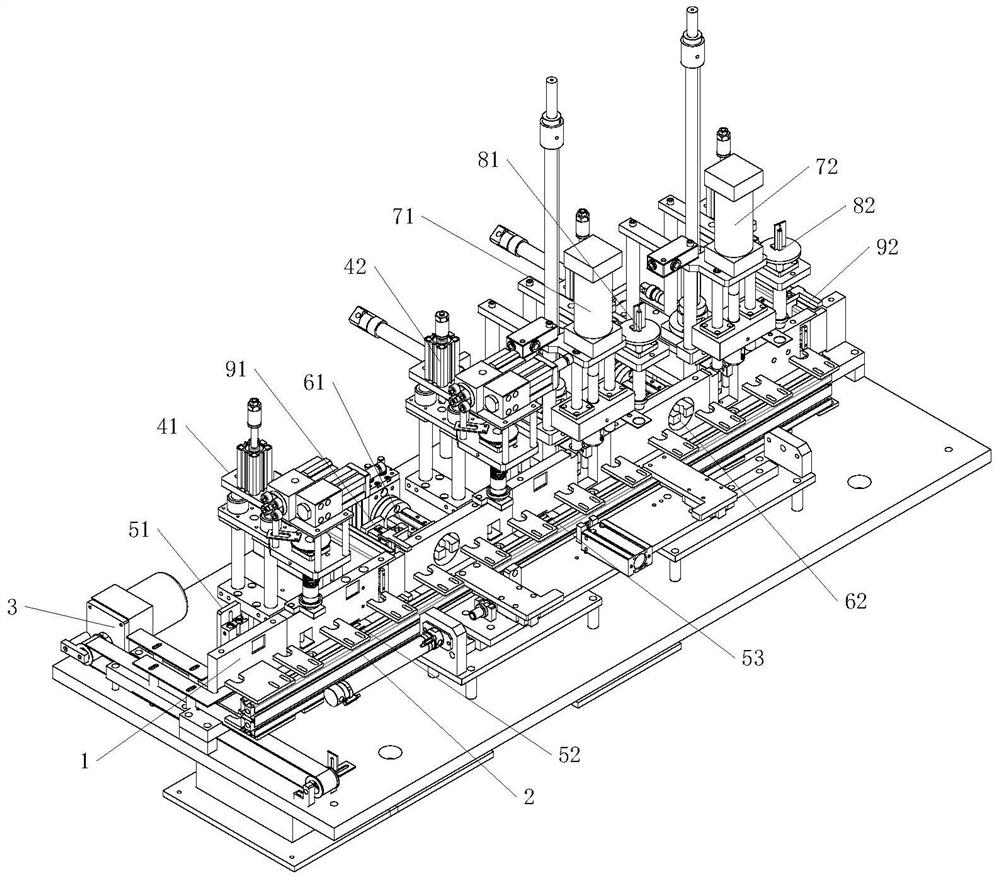

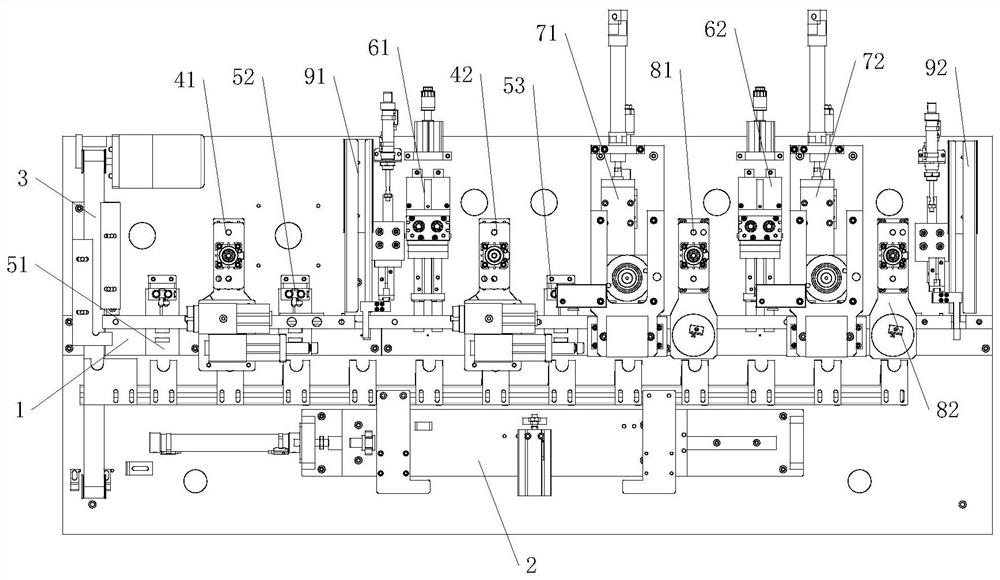

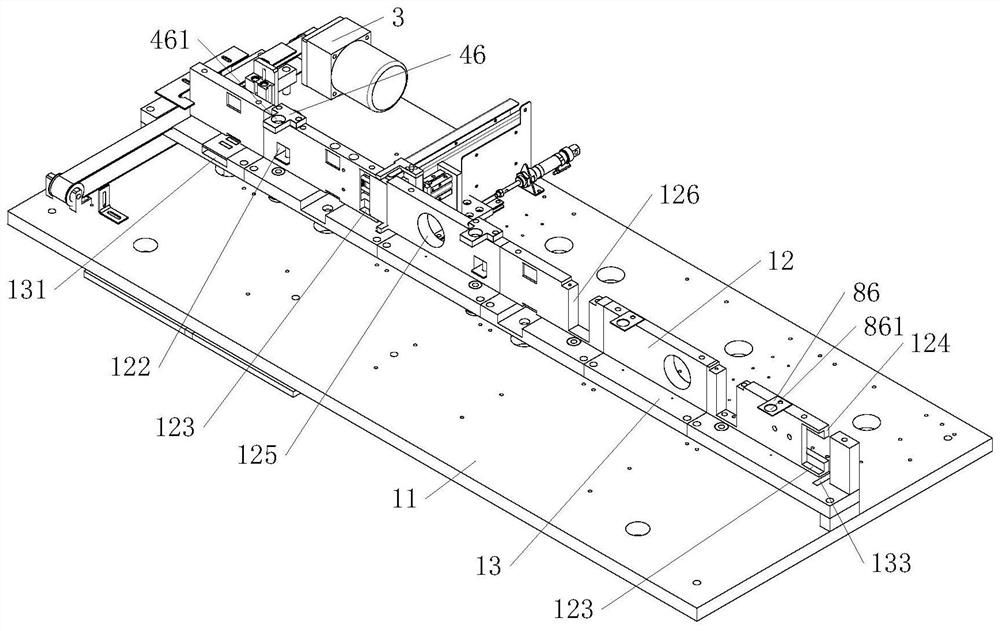

[0038] The present invention will be further described now in conjunction with accompanying drawing.

[0039] Such as Figure 1 to Figure 21 As shown, the automatic assembly device for dumbbell bearings includes: an assembly frame 1 for movingly placing dumbbell bearings 10, a material transfer device 2 arranged in parallel with the assembly frame 1, and a feeding device 3 located at one end of the material transfer device 2. The device 2 is used to move the dumbbell bearings 10 on the feeding device 3 to the assembly frame 1, and move the dumbbell bearings 10 on the assembly frame 1 to each station in sequence; Weighing device 51, the first greasing device 41 for adding grease, the second weighing device 52, the first sorting device 91 for removing unqualified dumbbell bearings 10, the second greasing device 42 , the first turning device 61 for turning over the dumbbell bearing 10, the third weighing device 53, the first tablet pressing device 71 for pressing the dust cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com