A connected metering and filling device for corrosive liquid

A filling device and corrosive technology, applied in the field of connected metering and filling devices, can solve the problems of low efficiency, lack of transfer and movement, etc., and achieve the effects of improving efficiency, easy promotion and application, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

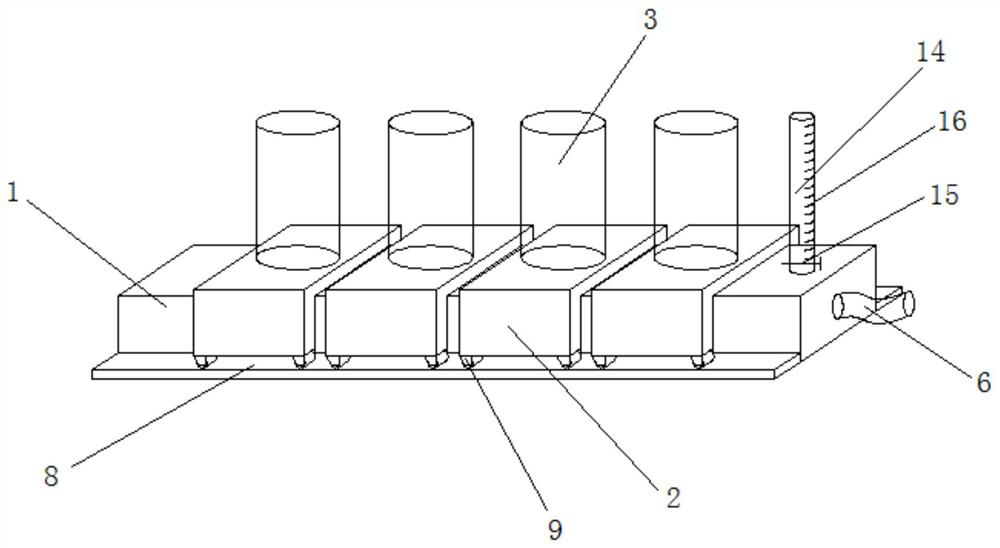

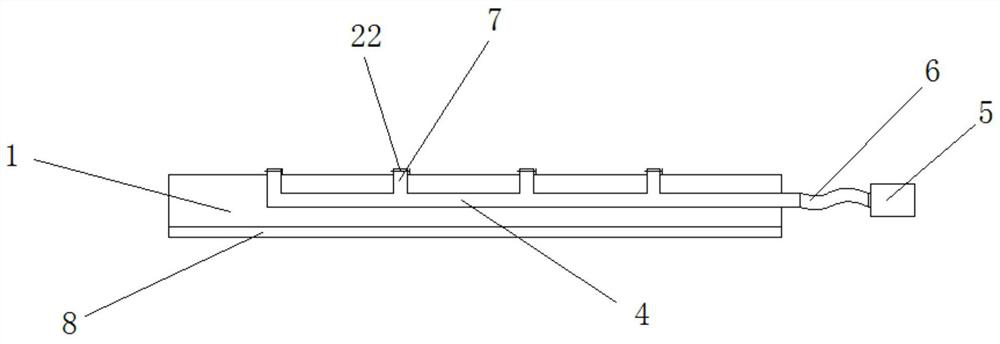

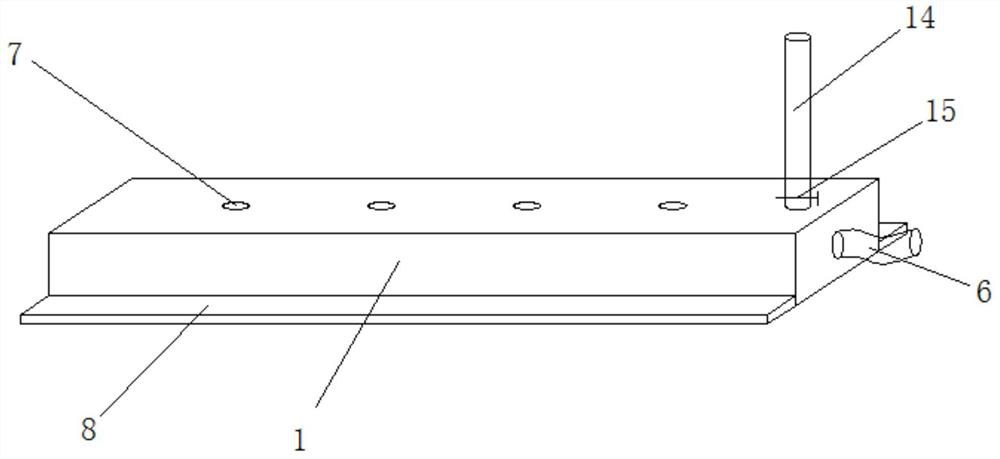

[0023] Embodiment 1: as Figure 1-4 As shown, a connected metering and filling device for corrosive liquids includes a base 1, a moving seat 2 and a barrel 3, the base 1 is elongated, and the moving seat 2 is provided with several groups. A through hole 18 is opened through the top of the moving base 2, and several groups of the moving base 2 are movably connected with the base 1; the moving base can straddle the upper part of the base and move.

[0024] The inner cavity of the base 1 is provided with a connecting pipe 4 whose right end runs through the right side of the base 1 and is fixedly connected with a hose 6, and the right end of the hose 6 is fixedly connected with a metering pump 5, and the top of the communicating pipe 4 The side is fixedly connected with several groups of butt joint tubes 7, the top of the butt joint tube 7 protrudes from the top of the base 1, the top of the right end of the communication tube 4 is fixedly connected with an observation tube 14, an...

Embodiment 2

[0031] Embodiment 2: as Figure 1-7 As shown, a connected metering and filling device for corrosive liquids includes a base 1, a moving seat 2 and a barrel 3, the base 1 is elongated, and the moving seat 2 is provided with several groups. A through hole 18 is opened through the top of the moving base 2, and several groups of the moving base 2 are movably connected with the base 1; the moving base can straddle the upper part of the base and move.

[0032] The inner cavity of the base 1 is provided with a connecting pipe 4 whose right end runs through the right side of the base 1 and is fixedly connected with a hose 6, and the right end of the hose 6 is fixedly connected with a metering pump 5, and the top of the communicating pipe 4 The side is fixedly connected with several groups of butt joint tubes 7, the top of the butt joint tube 7 protrudes from the top of the base 1, the top of the right end of the communication tube 4 is fixedly connected with an observation tube 14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com